IO-Link Safety: What it is and what is means

IO-Link Safety: What it is and what is means

April 17, 2024 | Blog Post, Venus Automation

The ever-evolving landscape of industrial automation demands robust, flexible, and safe solutions. Enter IO-Link, a communication protocol rapidly transforming how sensors and actuators interact with controllers in manufacturing environments. This blog post dives deep into the world of IO-Link, exploring its core functionalities, its safety extension (IO-Link Safety), and the advantages it brings to modern industrial automation systems.

Recent Posts

WHAT IS IO-LINK?

IO-Link is a communication protocol used in industrial automation enabling efficient communication between sensors, actuators, and controllers in industrial systems. The primary goal of IO-Link is to provide a point-to-point communication interface for smart devices in the field, allowing for seamless integration into the overall control system. IO-Link enables communication between a master device (such as a PLC or controller) and individual sensors or actuators, creating a point-to-point connection. It allows for the exchange of digital data between devices, providing more information and flexibility compared to traditional analogue connections. IO-Link also allows for the configuration and parameterization of connected devices, making it easier to set up and manage automation systems. This protocol supports bidirectional communication, allowing for real-time data exchange, diagnostics, and monitoring of connected devices. A key feature of these IO-Link devices are that they are typically designed for easy integration, and the protocol supports plug-and-play functionality, simplifying the installation and replacement of devices. IO-Link is an international standard (IEC 61131-9), ensuring compatibility between devices from different manufacturers.

WHAT IS IO-LINK SAFETY?

IO-Link Safety is an extension of the standard IO-Link communication protocol specifically designed for implementing safety-related communication in industrial automation systems. It allows for the integration of safety functions into the IO-Link architecture, enabling the transmission of safety-related data between safety devices and controllers. This extension enhances the flexibility and efficiency of safety solutions in manufacturing environments.

Functional Safety Fieldbus Profiles (FSCP), as standardized in IEC 61784-3, offers the possibility to conduct safe communication via certain communication channels such as backplane buses of a bus terminal. This is called “tunneling”. IO-Link can also be considered as a possible communication channel. However, such a solution is then not fieldbus-independent as expected from IO-Link, but a solution of the respective fieldbus profile and is also managed and accounted for by the corresponding fieldbus organization and not by the IO-Link community.

IO-Link Safety, on the other hand, is a fieldbus-independent safe communication profile that is tailored to the needs of IO-Link and standardized in IEC 61139-2. This means that safety devices only have to be developed once and not anew for each fieldbus variant. By adhering to the IO-Link Safety standard, manufacturers ensure interoperability and streamline the development process, ultimately leading to more efficient and cost-effective safety solutions in industrial settings.

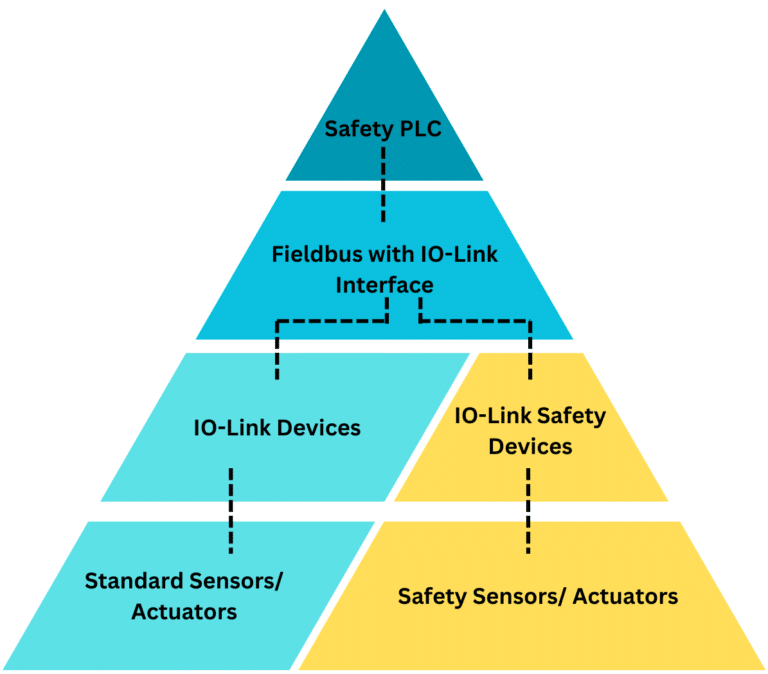

The architecture of the Io-link System

The Safety PLC: The Safety PLC (Programmable Logic Controller) is a dedicated controller responsible for managing and executing safety-related functions in an industrial automation system. It may interact with the IO-Link Safety Master through a fieldbus or another communication interface.

Fieldbus with IO-Link Interface: The Fieldbus is the communication network that connects various devices within an industrial automation system. In the context of IO-Link Safety, the Fieldbus includes an IO-Link interface to support communication with IO-Link devices, including both standard IO-Link devices and IO-Link Safety devices.

IO-Link Devices: IO-Link devices are standard sensors, actuators, and other industrial devices that communicate over the IO-Link protocol. These devices are part of the broader industrial automation system and can include sensors like proximity sensors, photoelectric sensors, and actuators like valves and motors. Standard IO-Link devices are typically used for non-safety-critical functions in the automation process.

IO-Link Safety Devices: IO-Link Safety devices are specifically designed for safety-critical applications within the industrial automation system. Examples of IO-Link Safety devices include safety light curtains, emergency stop buttons, and safety interlock switches. These devices communicate safety-critical information using the IO-Link Safety protocol, ensuring that the information is transmitted reliably and with a high level of integrity.

What can an IO-Link device do that a standard sensor cannot?

IO-Link devices supply three types of data:

Process data: Condition information that the IO-Link device reads and sends to the IO-Link master or information that the IO-Link master sends to the IO-Link device. Status information is also transmitted in this process. You can thus check whether the process data is valid.

Service data: Information that can be written to the IO-Link device or read from the IO-Link device.

Event data: Notifications such as error messages, which are sent from the IO-Link device to the IO-Link master as soon as the event occurs.

Other Benefits

Productivity: IO-Link devices furnish the controller with intricate condition data, offering invaluable insights for maintenance planning. Swift problem identification is facilitated, allowing users to schedule preventative measures promptly.

Simplicity: Installation becomes a breeze as standard cables and connectors are all that’s needed. Maintenance is hassle-free, thanks to the ability to monitor systems and tweak settings effortlessly. With IO-Link devices’ error detection feature, pinpointing issues becomes quick and straightforward. Even the replacement process is a cinch, as parameter data is conveniently stored in the controller.