5

Keeping Workers Safe: An Overview of Light Curtains

Understanding Light Curtains:

safety first in industrial environments

Ensuring worker safety in industrial environments requires advanced protective solutions, and Safety Light Curtains play a critical role in safeguarding personnel from hazardous machine movements. These intelligent safety devices create an invisible barrier that immediately stops dangerous machinery when an object interrupts the detection field, preventing injuries and ensuring compliance with safety regulations. Whether used for Body Protection in high-risk zones or for precision-focused Finger Protection in applications requiring fine handling, light curtains offer unparalleled versatility.

For environments requiring extended coverage, Long Range Safety Light Curtains provide comprehensive perimeter protection, making them ideal for safeguarding large machinery and automated production lines. Additionally, outdoor applications benefit from the robust design of Outdoor Light Curtains, ensuring continuous protection even in harsh conditions.

To further enhance safety automation, Safegate Muting Light Curtains integrate advanced muting capabilities, allowing materials to pass through designated areas without triggering a safety stop, optimizing workflow efficiency. With essential components like Muting Arms and Reer Light Curtain Accessories, these systems offer complete flexibility for various industrial applications.

In today’s industrial landscape, worker safety is paramount. By safeguarding personnel during interactions with machinery, businesses can significantly reduce accidents, boost productivity, and improve employee morale. Safety devices like light curtains play a vital role in fostering safe work environments, making them a crucial investment.

Light curtains, also known as light guards or safety light curtains, are electronic safety devices used extensively in industrial settings to protect personnel near hazardous machinery or areas. Their functionality is based on the interruption of invisible infrared light beams emitted by a transmitter and received by a receiver unit.

how light curtains work

TRANSMISSION AND DETECTION:

The transmitter unit emits a grid of infrared beams across the area requiring protection. The receiver unit, positioned opposite the transmitter, detects these beams using photodetectors.

BEAM INTERRUPTION AND SAFETY RESPONSE:

When an object or person enters the detection field and breaks one or more light beams, the receiver detects the disruption. This triggers the safety system’s programmed response, such as stopping or disabling machinery movement within milliseconds.

Safety Standards and Compliance:

Light curtains are designed and validated according to international safety standards (e.g., ISO 13849, IEC 61496) and local regulations (e.g., AS/NZS 4024 in Australia, EN 61496 in Europe). These standards ensure light guards provide reliable safety functions and meet stringent performance criteria.

KEY INFORMATION ABOUT LIGHT CURTAINS

Light curtains detect objects, typically human operators, within their sensing field. A disruption triggers a signal to connected machinery, prompting it to stop or enter a safe state.

Light curtains adhere to safety standards like AS 4024.1 and AS/NZS 4024.2019 in Australia, ensuring they meet strict safety requirements.

Light curtains are used in various industrial applications where operators need access to machinery or processes that could pose a risk, including:

Automated production lines, Robotic work cells, Presses and stamping machines, Packaging and material handling equipment.

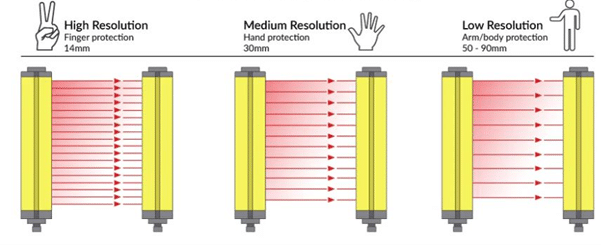

Determines the spacing between the light beams. Higher resolutions provide finer detection. Consider Venus Automation’s EOS4 X 14mm light curtain for high-resolution needs.

The vertical coverage range of the curtain, ensuring it safeguards the entire hazardous area. Venus Automation offers a wide range of light curtains with various protective heights, including the Admiral AX 90mm series.

How quickly the light curtain detects an obstruction and triggers a safety response. For applications requiring exceptionally fast response times, explore the Janus ML TRX light curtains offered by Venus Automation.

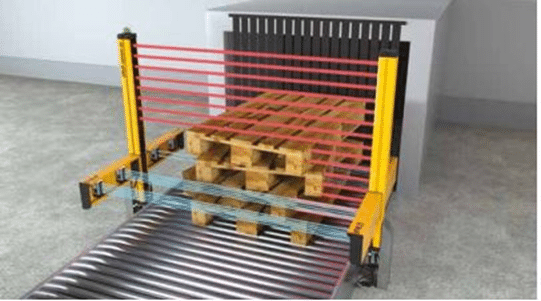

muting

Some light curtains incorporate advanced features like muting (temporarily disabling the safety function for controlled material passage) and blanking (ignoring specific areas within the detection field). Venus Automation’s SAFEGATE type 4 models by REER are programmable and can be configured for muting functions in various high-risk work environments.

calculation of safety distance

The position of the light curtain correlates with the effectiveness of the protection given by the light curtain. For maximum effectiveness, the light curtain must be positioned at a distance that it greater than or equal to the minimum safety distance because this would mean the access to the machine is only possible when any dangerous action by the machine has been ceased. The general formula for safety distance is as follows:

S = K * T + C

S – Minimum safety distance (mm)

K – Approaching speed of the body/ parts of the body (mm/s)

T – Total stopping time of the whole machine (s)

C – Additional distance (mm)

Conclusion

Light curtains are a valuable safety tool for industrial environments. By understanding their functionality, benefits, and considerations, you can make informed decisions to safeguard your workforce and create a safer work environment.

Looking for Light Curtains?

Venus Automation offers a comprehensive selection of light curtains from leading manufacturers to suit your specific needs and safety requirements. Visit our website or contact