Be Bold: DOLD’s Industrial Solutions

Ensuring Precision and Safety: A Look at DOLD's Cutting-Edge Modules

August 23 2024 | Blog Post, Venus Automation

In today’s rapidly advancing industrial landscape, the demand for precision, reliability, and safety has never been greater. DOLD, a leading name in automation technology, offers an array of innovative safety modules designed to meet these rigorous demands. From delay modules to emergency stop devices, and from remote control systems to multifunctional safety modules, DOLD’s cutting-edge solutions are essential for safeguarding both machinery and operators. This blog delves into DOLD’s most advanced products, highlighting their crucial role in maintaining seamless and secure industrial operations.

Exploring DOLD’s Essential Modules: From Delay to Safety Monitoring

DOLD – BG 7925 and LG 7928 delay modules are designed to introduce precise timing delays in industrial processes. These modules are vital in applications requiring controlled sequencing, such as motor startups or emergency stops. By allowing a preset delay before triggering connected devices, these modules help prevent mechanical stress and enhance system longevity, ensuring operations run smoothly without sudden interruptions.

Emergency stops are a critical component in any industrial safety system, and DOLD offers a range of options. The BH 5928 and LG 5925 provide reliable emergency stop capabilities that can immediately halt machinery in case of danger. These modules ensure that operators can quickly intervene when safety is compromised. Paired with the UF 6925 emergency stop module, DOLD’s solutions offer comprehensive protection, whether for individual machines or complex systems.

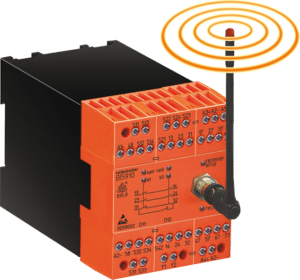

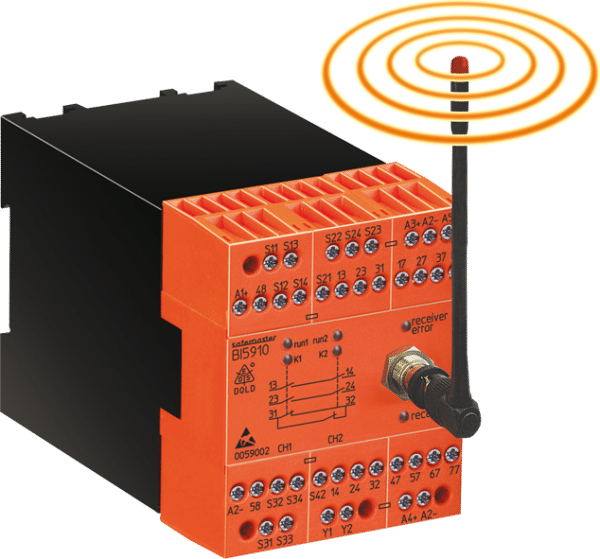

Wireless control offers flexibility and ease in industrial environments. The BI 5910, RE 6910, and UH 6900 modules bring radio-controlled safety to the forefront. Designed for remote control applications, these modules can activate safety mechanisms without direct contact, making them ideal for hazardous environments. DOLD’s radio-controlled systems ensure safety across long distances while maintaining precise control over critical functions.

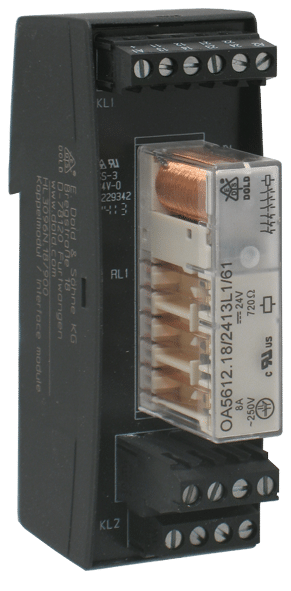

For smooth operation across complex systems, the HL 3096N and HC 3096N interface modules enable seamless communication between different control elements. These modules act as bridges, ensuring that different systems can work together without error. Whether it’s signal conversion or galvanic isolation, DOLD’s interface modules help industrial processes stay connected and efficient.

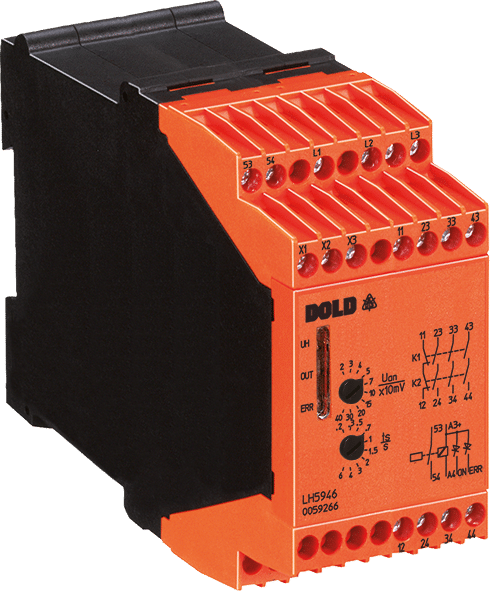

DOLD’s LH 5946 standstill monitor and UH 5947 speed and standstill monitor ensure that critical equipment operates within safe parameters. Monitoring key metrics such as speed, standstill, and frequency, these devices provide real-time feedback and prevent potential accidents. The UH 6937 goes a step further by tracking both speed and frequency, making it indispensable for processes requiring strict regulation of rotational equipment.

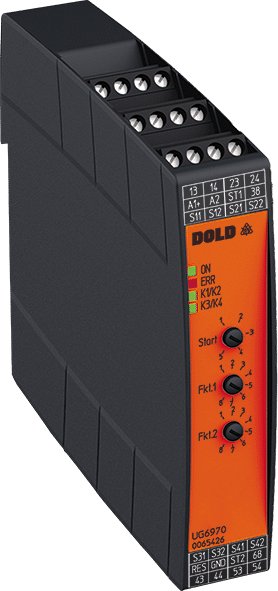

Versatility meets safety with the UG 6970 multifunctional safety module. This device is designed for varied safety tasks in industrial environments, such as monitoring different safety inputs and triggering appropriate outputs. Additionally, the RE 6909 three-stage enabling switch ensures operator safety by requiring intentional activation. Whether during setup or emergency situations, these modules provide essential control to keep operations secure.

Industry Applications

Automotive Manufacturing: DOLD’s delay modules and emergency stop systems play a critical role in automotive manufacturing. The delay modules are designed to ensure precise timing in operations, such as coordinating the start and stop sequences of machinery, which is crucial for maintaining smooth and efficient production lines. Emergency stop systems are integrated into high-speed assembly lines to provide immediate response capabilities, quickly halting machinery to protect workers from potential accidents or malfunctions. This combination of timing precision and rapid response contributes significantly to maintaining safety and operational efficiency in automotive manufacturing environments.

Robotics: In the robotics sector, DOLD’s standstill monitors and enabling switches are vital for ensuring safety during the programming, maintenance, and operation of robotic systems. Standstill monitors detect and prevent unintended movements of robots when they are in a stationary state, which is crucial during setup or maintenance procedures. Enabling switches are used to ensure that robotic arms or machines only operate when it is safe to do so, preventing accidental activation that could lead to injuries. These safety features help mitigate risks and enhance operational reliability in environments where precision and safety are of utmost importance.

Chemical Processing: In the chemical processing industry, DOLD’s radio-controlled safety modules provide a critical layer of safety by enabling operators to manage hazardous processes from a safe distance. These modules allow for remote control of equipment and processes, reducing the need for operators to be physically present in potentially dangerous areas where toxic substances or extreme conditions may be present. This remote operation capability not only minimizes exposure to hazardous chemicals but also improves the overall safety and efficiency of chemical processing operations by allowing for better control and monitoring from a safer location.

Technical Insights

DOLD BG 7925 Delay Module: Precision Timing with Adjustable Settings

The BG 7925 delay module features an adjustable time delay range of 0.05 seconds to 300 hours, making it highly versatile for various industrial applications. It supports both on-delay and off-delay functions, which can be selected via a front-panel switch. Installation is simplified with a DIN-rail mounting design, and the module is equipped with screw terminals for secure and reliable connections. The compact design, along with a wide operating voltage range of 24 to 240 V AC/DC, ensures compatibility with diverse systems. Its high accuracy in timing, combined with robust construction, minimizes wear and tear on connected devices, thereby extending system life.

DOLD UH 6900 Radio-Controlled Safety Module: Advanced Wireless Control

The UH 6900 radio-controlled safety module operates on the 868 MHz ISM band, providing a reliable and interference-resistant communication link. With a transmission range of up to 100 meters in open space, it ensures flexibility in hazardous environments where direct access is limited. The module is designed for easy integration, featuring a user-friendly interface for pairing and configuration. It supports multiple safety functions, including emergency stop and machine control, with a response time of less than 20 milliseconds, ensuring quick and precise activation. Additionally, the module is equipped with LED indicators for status monitoring, facilitating easy troubleshooting.

DOLD LH 5946 Standstill Monitor: Reliable Safety Through Accurate Detection

The LH 5946 standstill monitor is engineered for critical applications where the detection of motion or the lack thereof is crucial for safety. It features a sensor input that can monitor rotational speed down to 0.1 Hz, ensuring precise detection of standstill conditions. The monitor includes a relay output that can be configured to trigger safety circuits when motion ceases, offering a fail-safe mechanism. The unit is designed for easy installation on a DIN rail and includes a front-facing LED display for real-time monitoring of the operational status. The LH 5946 is also equipped with an adjustable delay time, allowing it to accommodate specific application needs, making it ideal for use in high-inertia systems where motion deceleration is gradual.