Safety sensors and switches play a critical role in industrial safety systems by monitoring hazardous areas, detecting unsafe conditions, and controlling machine operations. These devices…

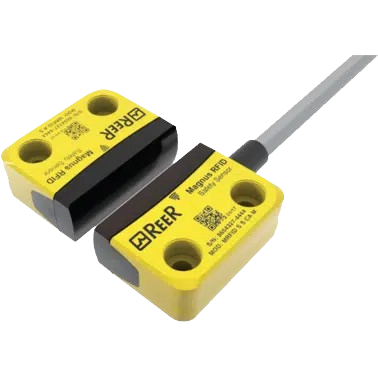

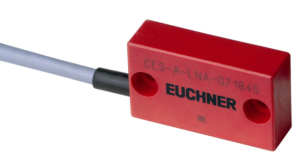

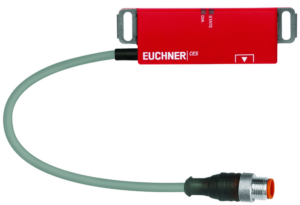

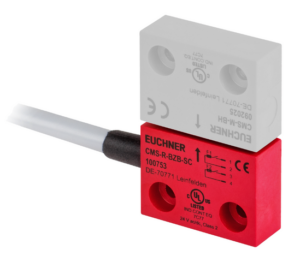

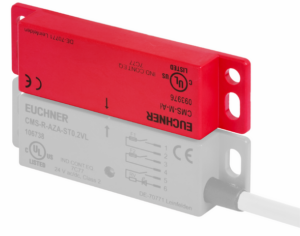

Safety sensors and switches play a critical role in industrial safety systems by monitoring hazardous areas, detecting unsafe conditions, and controlling machine operations. These devices help prevent accidents by ensuring that machines respond appropriately when unauthorized access, dangerous movements, or unsafe conditions occur. Safety sensors and switches work in tandem with safety controllers to provide a failsafe system that protects both operators and equipment.

Key Features:

- Precise Hazard Detection: Monitors machine status and detects abnormal conditions in real time.

- Versatile Sensor Types: Includes position sensors, proximity switches, and optical safety sensors to suit various safety needs.

- Durable Construction: Built to withstand industrial environments, including dust, moisture, and extreme temperatures.

- Fail-Safe Operation: Designed with redundancy and self-checking features to ensure reliable performance.

- Compatibility: Easily integrates with safety relays, controllers, and emergency stop circuits.

Common Types of Safety Sensors and Switches:

- Safety Limit Switches: Detect the position of machine parts or access points.

- Safety Proximity Sensors: Detect the presence of objects without direct contact.

- Interlock Switches: Ensure that safety gates and doors remain closed during operation.

- Photoelectric Sensors: Use infrared beams to detect objects and intrusions.

- Pressure Mats: Detect operator presence by sensing weight in hazardous zones.

Typical Applications:

- Machinery safeguarding for automated production lines

- Safety door monitoring for enclosures and robotic cells

- Perimeter protection in hazardous work zones

- Position monitoring for moving parts and assembly lines

Benefits of Safety Sensors and Switches:

- Enhanced Safety: Prevents unauthorized access to hazardous areas and stops machinery during unsafe conditions.

- Operational Efficiency: Allows automated monitoring and control, reducing the need for manual supervision.

- Flexibility: Suitable for a wide range of machinery and industrial processes.

- Compliance: Helps meet regulatory safety standards, ensuring adherence to industry guidelines (e.g., ISO 13849, IEC 60204).

Safety sensors and switches are essential for maintaining a safe working environment, providing accurate and reliable detection of hazards, and ensuring that machines operate only when conditions are safe. Their versatility and robust design make them indispensable components in modern industrial automation and safety systems.