26

Safety Light Curtain Installation Guide

Understanding Safety Light Curtains

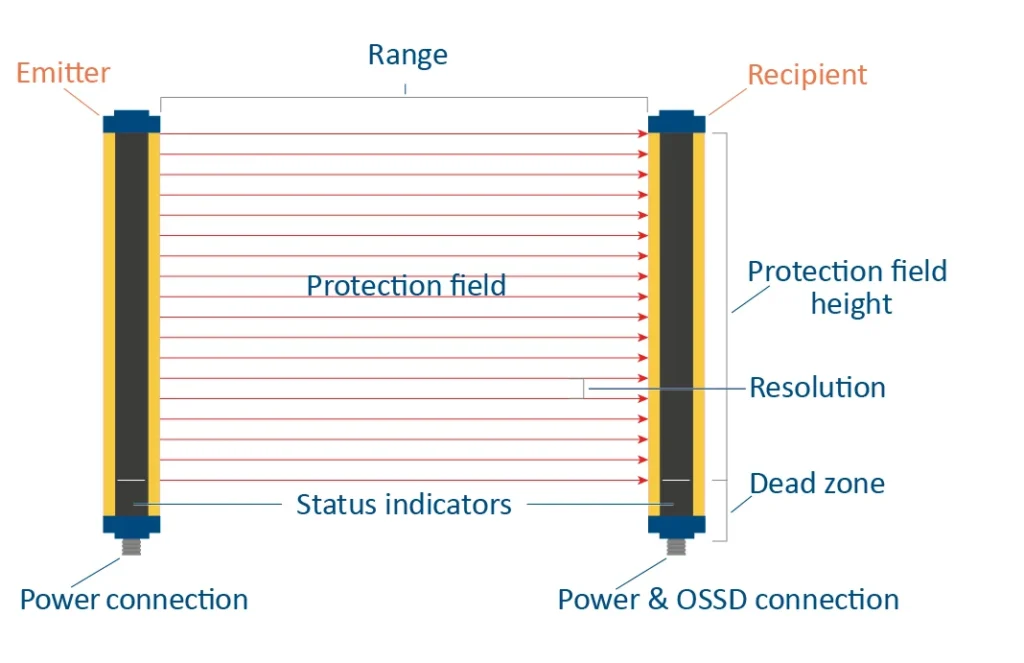

What Are Safety Light Curtains?

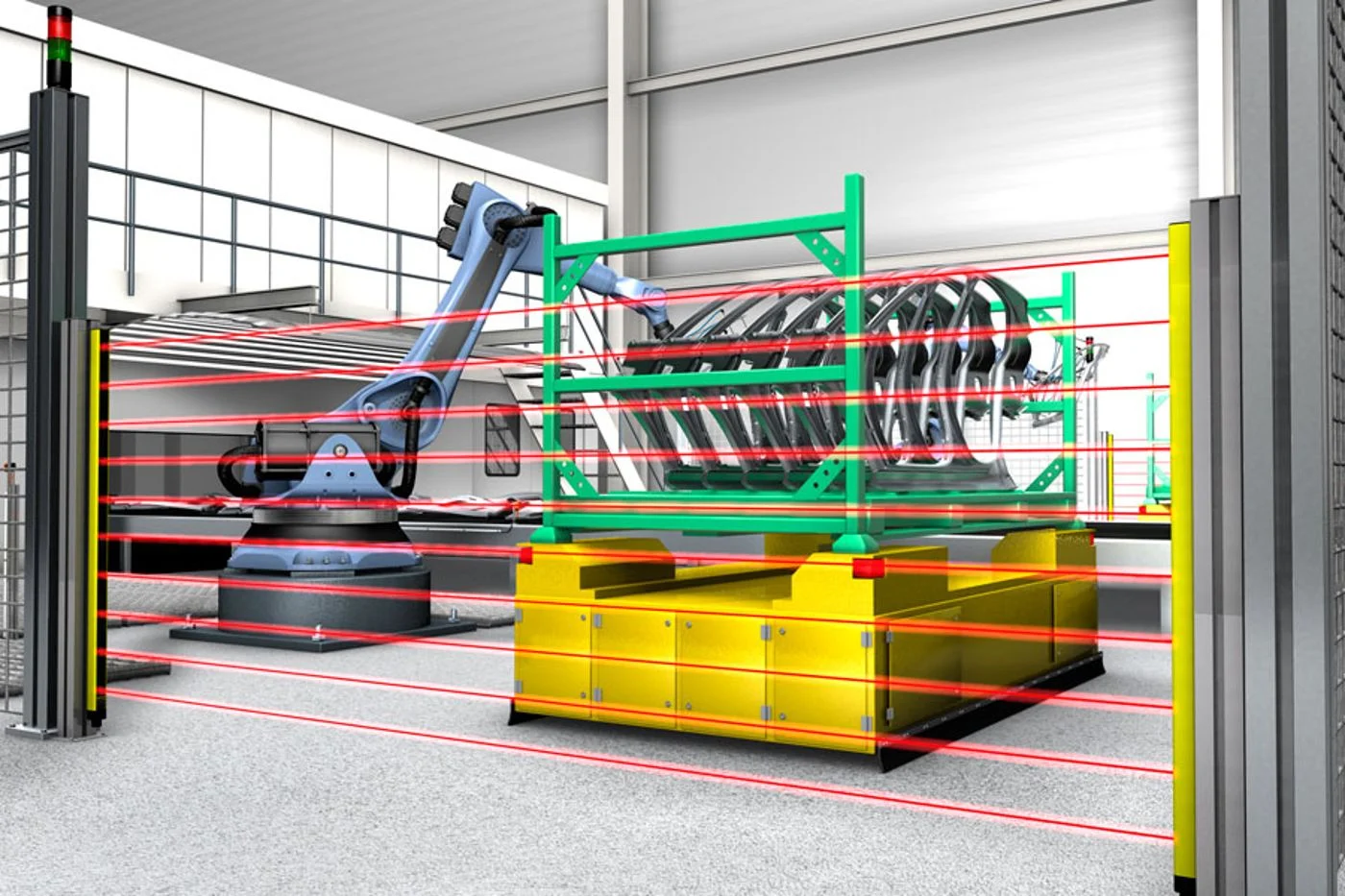

Safety light curtains are non-contact protective devices that safeguard workers around hazardous machinery. These systems use infrared beams between an emitter and receiver to create an invisible field. If any object interrupts a beam—like a finger, hand or larger body part—the system sends a stop signal to the machine, preventing injury. They are widely used in robotic cells, presses, and automated production lines where regular human access is required. By eliminating bulky physical guards, light curtains boost both safety and productivity—key for modern industrial automation.

Key Components

A typical system includes:

- Emitter & Receiver: Form the infrared beam curtain.

- Control Unit or Safety Relay: Processes signals and initiates safe machine stoppage.

- Mounting Hardware: Ensures proper positioning and alignment.

- Muting & Blanking: Allow safe workflow interruptions without unnecessary stops.

These components work together to meet stringent safety standards and ensure seamless integration into automated systems.

Benefits of Safety Light Curtains

Enhanced Industrial Safety

Unlike traditional guards, safety light curtains stop machines instantly when someone enters the hazardous zone. They help prevent accidents with equipment like palletizers, robotic arms, or hydraulic presses. Engineered to meet standards like ISO 13855 and IEC 61496, these systems offer detection resolutions for fingers, hands, or full bodies—ideal for varied industrial applications.

Improved Workflow Efficiency

By replacing mechanical guards, light curtains speed up maintenance, adjustments, and material handling. Features like muting and blanking enable smooth production flow even when objects pass through the protected zone. Integration with safety PLCs makes them ideal for flexible, high-speed operations

Types of Light Curtains

Standard models offer reliable finger, hand, or body detection. Commonly used with presses, conveyors, and molding machines, they are compact, easy to install, and compatible with most safety controllers. Features include cascading for multi-sided protection, automatic restart, and diagnostic indicators for efficient troubleshooting.

Special Application light curtains can be designed for demanding environments, suiting washdown zones (IP69K), ATEX-rated explosive areas, or outdoor installations. Alternatively, they can feature extended ranges, configurable beam spacing, or built-in logic for complex workflows. Ideal for guarding robotic cells, transfer stations, or automated warehouses, these handle niche safety challenges without compromising performance.

Choosing the Right Light Curtain

Match Protection to the Process

Selection starts by assessing the risk level and workflow. For example:

- Finger or hand detection is crucial for operators working near cutting or packaging machinery.

- Full-body detection suits perimeter safety in automotive or palletizing areas.

- Environmental factors like washdown requirements or high dust levels should also guide product choice.

Consider Features: Restart, Muting, Blanking

- Manual vs. Automatic Restart: Manual restart enhances safety where frequent access occurs; automatic restart supports fast-paced automated systems.

- Muting: Temporarily disables beams for materials in transit—perfect for conveyors or robotic lines.

- Blanking: Ignores fixed objects in the beam path without halting operations, ideal for guarding fixtures or stationary tools.

Choosing the right features ensures safe and efficient operation.

Installation Planning

Site Assessment

Identify all hazardous access points and understand how operators interact with machinery. If workers reach into presses or cutting zones, install curtains with high-resolution detection. Physical layout, ambient lighting, and moving materials can affect light curtain performance. A thorough site survey ensures effective placement without workflow disruption.

Compliance with Safety Standards

Light curtains must comply with ISO 13855, IEC 61496, and relevant Work Health and Safety (WHS) codes. The system’s distance from the hazard must be calculated to ensure the machine halts before a person can reach the danger zone. Features like muting and blanking should also be configured according to safety guidelines to maintain compliance.

Installation Essentials

Correct Positioning

Installers must match the resolution to the risk. Finger or hand protection requires closer proximity than full-body protection. Use vertical mounting for openings and horizontal for perimeter detection. Ensure the sensor field remains unobstructed and stable. Reflective surfaces and vibration should be accounted for to maintain reliable performance.

Wiring and Integration

Connect the light curtain to a safety relay or safety PLC per the manufacturer’s diagrams. Ensure all cabling is shielded where necessary and protected from mechanical wear. LED indicators help confirm correct beam alignment before startup.

Testing and Calibration

Verify the system halts machine operation when beams are interrupted. Simulate real intrusion scenarios at various points in the field. Advanced models may include auto-alignment or diagnostics to speed up testing and ensure long-term reliability. Keep documented results for audits and safety checks.

Installers must match the resolution to the risk. Finger or hand protection requires closer proximity than full-body protection. Use vertical mounting for openings and horizontal for perimeter detection. Ensure the sensor field remains unobstructed and stable. Reflective surfaces and vibration should be accounted for to maintain reliable performance.

Connect the light curtain to a safety relay or safety PLC per the manufacturer’s diagrams. Ensure all cabling is shielded where necessary and protected from mechanical wear. LED indicators help confirm correct beam alignment before startup.

Verify the system halts machine operation when beams are interrupted. Simulate real intrusion scenarios at various points in the field. Advanced models may include auto-alignment or diagnostics to speed up testing and ensure long-term reliability. Keep documented results for audits and safety checks.

Ongoing Maintenance & Testing

Routine Inspections

Scheduled inspections ensure performance and compliance. Check alignment, clean optics, and verify beam integrity. Watch for physical damage or contamination that could affect performance. Testing should simulate realistic safety breaches to confirm system function. Any issues must be addressed immediately.

Maintenance Best Practices

- Clean sensor surface gently with non-abrasive materials.

- Avoid compressed air, which may push debris into sensitive areas.

- Inspect wiring for wear or stress.

- Maintain logs for maintenance and incidents—helpful for audits and predictive maintenance.

Troubleshooting Safety Light Curtains

Installation Issues

Misalignment is the most common issue. Use laser tools or built-in indicators to confirm accurate beam alignment. Improper mounting height can leave gaps in protection—e.g., installing too high might allow hands to slip under the detection field. Always follow ISO and manufacturer guidelines. Improper integration with the machine’s safety circuit can cause the system to malfunction. Verify connections to relays, emergency stop systems, and PLCs.

Diagnostic Alerts

Modern light curtains display diagnostic codes or LED status indicators. Blocked beams from dust or clutter are common and easily resolved by cleaning optics and removing interference. Recurring muting or blanking errors may point to misconfiguration or environmental shifts. Check settings and ensure sensors aren’t being triggered by unintended movement or reflections. Power supply issues or faulty cables can also cause errors. Check voltage and cable integrity, and refer to the manufacturer’s manual for code interpretation.

Governance and Safety Culture

Document Everything

Keep complete records of selection, installation, testing, and maintenance. Include wiring diagrams, test logs, and compliance certificates. This documentation is essential for ISO or WHS audits and resolving any future incidents.

Train Your Team

Operators and technicians must understand how light curtains work, how to respond to alerts, and the risks of bypassing safety features. Training should cover emergency procedures, fault codes, and routine checks. Periodic refresher training keeps your team aligned with evolving standards and technologies.

Trends in Light Curtains

As factories become more automated and connected, safety light curtain technology continues to evolve:

- IO-Link & Industry 4.0: Modern curtains provide real-time diagnostics for predictive maintenance and remote monitoring.

- Slim Designs: Space-saving models suit tight installations like robotic arms or electronics assembly lines.

- Integrated Logic: Built-in muting and blanking reduce the need for external modules—simplifying installation.

- Enhanced Optical Performance: Advanced filtering improves immunity to ambient light or reflections for reliable detection in harsh settings.

Beyond Light Curtains – Safety Monitoring & Output Products

While selecting a robust safety input method is vital to any industrial safety system, equally critical is the ability to monitor and respond appropriately to those inputs. The safety monitoring and output range at Venus Automation provides tailored solutions to meet the needs of diverse machines and projects.

A key component in modern safety systems is the safety PLC. These programmable devices allow custom safety logic, with flexible input/output terminal assignments. Venus Automation offers a variety of models, including the MOSAIC PLC from ReeR, Samos PLC from Wieland, and GEMNIS PLC from Pizzato—each delivering advanced and reliable safety functionality.

Where complex programmability is unnecessary, alternative options such as safety relays are available. These include standalone relays, time-delay relays, speed-monitoring relays, standstill monitoring and timer relays, PCB relays and relay expansion modules. Also important are type-specific control relays, like the emergency stop relay, safety edge relay, light curtains relay, or two-hand control relay. These options provide effective and application-specific safety responses.

Regardless of input device or control relay, the emergency stop remains integral to any safety architecture, albeit not providing direct monitoring. To provide a complete solution, emergency stop accessories are also available, as well as emergency stop variants such as rope pull switches, and standard non safety-rated pushbuttons. Emergency stops are also sold integrated on other safety monitoring devices such as two-hand stations. Finally, Wireless safety systems, including wireless emergency stop units or remote controls and accessories, are also available.

Additional safety monitoring components include the safety encoder, which monitors motor speed, and interlock devices such as tongue solenoid interlock switch or electro-magnetic switches. For more complex safety guarding, multifunctional gatebox units provide a consolidated interface, easily mounted on protective enclosures, such as concertina guards.

Access restriction and control can also be achieved through electronic key systems, ensuring machinery operates only under authorized conditions. To connect chosen elements together, contact blocks are readily available. Finally, for output-side protection, safety contactors and pneumatic safety valve solutions are available to ensure reliable machine stoppage when hazardous conditions are detected.