Introduction to Operator Interfaces What Are Operator Interfaces? Industrial operator interfaces are devices designed for machine control and system navigation in demanding automation environments. Whether…

Introduction to Operator Interfaces

What Are Operator Interfaces?

Industrial operator interfaces are devices designed for machine control and system navigation in demanding automation environments. Whether mounted on equipment or built into operator panels, these pads facilitate safe operation through precise control interfaces such as tactile keypads, mechanical interlocks, and intuitive touchscreen interfaces.

Role in Modern Industrial Automation

Operator interfaces are central to key systems that manage workflows across sectors like manufacturing, robotics, and process control. By enabling direct interaction with advanced PLC control capabilities, they support complex control tasks with speed, accuracy, and efficient control logic. Their use spans from mobile devices in remote applications to fixed control stations on the factory floor.

Benefits of Using Our Operator Interfaces in Machinery

Industrial operator interfaces offer a go-to solution for OEMs and integrators seeking:

- Reliable operation in hazardous locations

- Graphical interfaces for real-time visualization

- Ergonomic control layouts that minimize fatigue

- Support for advanced control features like diagnostics, feedback, and real-time status updates

Key Features of Industrial Operator Interfaces

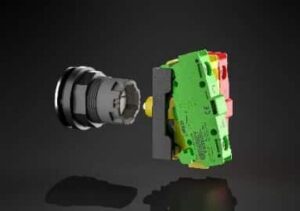

Rugged Design and Durability

With robust housings made of impact-resistant plastics or metals, industrial operator interfaces are built to endure vibration, dust, oil, and even direct washdowns. Their durability ensures reliable operation in industrial applications such as automotive assembly, mining equipment, and heavy-duty manufacturing.

IP Ratings and Environmental Protection

Most industrial operator interfaces come with IP65, IP66, or IP67 ratings, shielding internal components from water and particulates. This makes them ideal for hazardous locations or harsh process zones where exposure to liquids or debris is common.

Ergonomic Layout and User Interface

A core feature of modern operator interfaces is their ergonomic design, which enhances ease of use and operator productivity. Controls are spaced and sized for intuitive use, minimizing operational errors. This is especially valuable during high-speed operations or shift rotations.

Compatibility with PLCs and HMIs

Operator interfaces integrate effortlessly with leading PLC systems, such as those from Mitsubishi, through analog, digital, or networked outputs. They serve as operator panel extensions or standalone machine control units, supporting ladder logic, scripting, and advanced PLC control actions.

Safety Compliance and Certifications

Designed to support safe operation, many units come with:

- Built-in selector switches and E-Stop buttons

- CE, UL, and RoHS certifications

- Compatibility with mechanical interlocks and safety relays

These safety measures make our operator interfaces ideal for machines with hazardous energy sources or requiring controlled access control systems.

Types of Industrial Operator Interfaces

Touchscreen Control Pads

Touch screen models offer graphical interface displays with programmable layouts that adapt to different tasks and workflows. Ideal for process visualization or SCADA systems, these models allow operators to interact with sensors, alarms, and setpoints via swipes or taps — even with gloved hands in many cases.

Membrane Switch Pads

Membrane pads provide flat, compact size interfaces that are resistant to chemicals and dust, commonly used in medical and food processing industries. They combine low-profile design with flexible integration of control into operator panels or enclosures.

Keypad-Based Control Units

Traditional tactile models use mechanical interlocks, selector switches, or programmable rubber domes to manage discrete I/O or function-based macros. These units excel in scenarios requiring robust feedback, like robotic systems or material handling equipment.

Wireless and Remote-Control Interfaces

Operator interfaces with wireless capabilities are ideal for mobile devices or remote machine access. Used in mining, construction, or AGV control, they offer safe operation through encrypted protocols, reliable signal feedback, and high-range connectivity.

Applications of Operator Interfaces in Industry

Manufacturing and Assembly Lines

In high-volume manufacturing, operator interfaces enable operators to initiate sequences, change tooling modes, and manage errors quickly. Their reliable operation reduces bottlenecks, while ergonomic design supports shift-based human interaction.

Packaging and Material Handling

From labeling machines to carton sorters, operator interfaces provide precise control over conveyor direction, speed, and timing. Integration with sensors ensures efficient control over automated systems, especially when paired with mechanical safety interlocks.

Robotics and CNC Machinery

Operator interfaces connect with robot controllers and CNC systems to allow for real-time manual overrides, jogging, or reprogramming. Their graphical interfaces and selector switches offer streamlined options for complex control tasks like tool changes, calibration, and emergency shutdowns.

Process Control and Monitoring

In chemical plants, water treatment, and HVAC systems, operator interfaces allow engineers to adjust parameters, monitor alarms, and execute safety routines with intuitive touchscreen interfaces or keypad configurations. These are often integrated into distributed control systems (DCS) or SCADA platforms.

Choosing the Right Operator Interface

Voltage and Interface Requirements

Operator Interfaces support a variety of voltage inputs — typically 12V to 24V DC — and output formats like analog, digital, or serial. Depending on the need, they can include selector switch, E-Stop, or multifunction pushbutton capabilities with visual and tactile feedback.

Number of Inputs and Outputs

When choosing a model, assess the number of I/O points needed. Simple tasks may require just a few digital inputs, while complex control tasks like multi-axis robot control may need 10+ programmable functions or macro keys.

Resistance to Harsh Environments

For hazardous locations, select models with sealed enclosures, IP-rated protection, and robust housings that withstand shock, vibration, chemicals, and high humidity.