Palazzoli accessories and mounting hardware are essential components in industrial electrical installations. Known for their robust build and innovative design, these accessories ensure secure fitting, enhanced protection, and long-term performance in demanding environments. Whether you’re dealing with control panels, junction boxes, or cable management systems, Palazzoli offers an extensive range of compatible and durable solutions suited for electrical supply and heavy-duty electrical equipment applications.

Importance of Mounting Hardware in Industrial Installations

Enhancing Safety and Stability

In industrial settings, safety and structural integrity are paramount. Palazzoli mounting hardware—such as metal brackets and plaster brackets—ensures secure and vibration-resistant installation of electrical products. These components support reliable operation by preventing movement and misalignment that could lead to equipment failure or hazards during use.

Protecting Electrical Components

Properly installed mounting systems shield sensitive electrical equipment from mechanical stress, impact, and environmental exposure. This is especially critical in settings where dust, moisture, or chemical exposure can affect circuit integrity. Mounting hardware provides a high level of protection, preserving the longevity and functionality of enclosures.

Key Features of Palazzoli Products

High-Quality Materials

Palazzoli products are manufactured using corrosion-resistant stainless steel, zinc-coated metals, and high-durability polymers. This ensures resistance to harsh industrial conditions and contributes to consistent, reliable operation.

Customization Options

Palazzoli offers customization for various installation scenarios. Whether it’s adjusting bracket size, designing for specific enclosures, or selecting the correct fitting kits, these tailored options improve compatibility with a wide variety of electrical supply systems.

Precision Engineering

Engineered with precision, Palazzoli accessories guarantee accurate alignment, optimal load distribution, and minimal installation time. Their hardware is designed to meet tight tolerances, reducing field errors and enhancing installation efficiency.

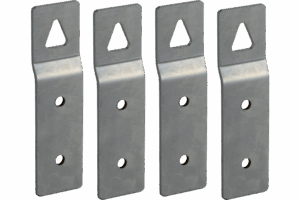

Understanding Electrical Mounting Brackets

Types of Mounting Brackets

Palazzoli provides multiple bracket types for different use cases:

- Metal brackets for securing enclosures to steel frames

- Plaster brackets for wall-integrated setups

- Wall-mounted installation kits for fixed box applications

These brackets accommodate a range of enclosure sizes, making them suitable for diverse electrical installation needs.

Benefits of Using Mounting Brackets

Mounting brackets improve safety, cleanliness, and accessibility of electrical systems. They allow for:

- Quick wall-mounted installation

- Reduced mechanical strain on cables & connectors

- Optimized airflow around components

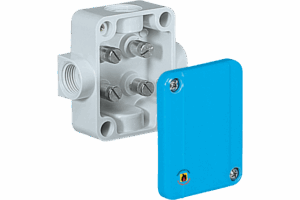

Wall Mounting Kits for Electrical Boxes

Installation Process

Palazzoli’s wall mounting kits simplify the wall-mounted installation of electrical boxes on various surfaces like concrete, plasterboard, or metal. Kits include pre-drilled plates, fastening bolts, and clear product details, ensuring secure and correct fitting every time.

Safety and Compliance Standards

All mounting kits meet rigorous IEC standards and local compliance codes. The components support proper clearance and secure fitting, meeting a high level of protection required for modern industrial electrical supply environments.

Overview of IP66-Rated Mounting Hardware

Characteristics of IP66 Certification

The IP rating of IP66 signifies complete protection against dust ingress and powerful water jets. Palazzoli’s IP66-rated mounting hardware guarantees high environmental resistance for electrical enclosures and accessories.

Applications in Harsh Environments

These components are ideal for outdoor or high-moisture areas like food processing plants and marine docks. The high IP rating ensures that sensitive electrical equipment is safeguarded even in extreme conditions, supporting reliable operation in critical systems.

Advantages of Using IP66-Rated Products

Ensuring Durability and Longevity

IP66-rated products from Palazzoli offer long service life by preventing corrosion and internal damage. Their ruggedness translates to lower maintenance and increased safety, especially in industrial electrical supply chains.

Enhancing Operational Efficiency

With fewer maintenance interruptions and improved protection, facilities using Palazzoli mounting hardware benefit from streamlined performance and reduced risk—leading to more reliable operation and fewer costly downtimes.

Comprehensive Range of Industrial Electrical Accessories

Selection and Compatibility

Venus Automation stocks a wide range of Palazzoli accessories, including fastening kits, cable glands, vent plugs, and brackets—ensuring perfect fit across new and legacy electrical supply products.

Meeting Industry Standards

Palazzoli hardware is designed to comply with global standards such as IEC, EN, and UL. Full product details are available for all items to aid in engineering planning and project compliance checks.

Innovations by Palazzoli in Electrical Solutions

Recent Product Developments

Palazzoli continues to develop advanced mounting hardware with new locking systems and pre-assembled modular kits. These innovations help speed up wall-mounted installations while maintaining strong environmental IP ratings.

Application-Driven Innovations

Feedback from industries such as mining, logistics, and wastewater has inspired more robust solutions capable of handling tough environments. These improvements help operators meet high levels of protection required in critical applications.

Customization for Specific Project Needs

Tailoring Solutions for Unique Challenges

Palazzoli provides tailored mounting and accessory solutions for projects with space constraints, environmental challenges, or specific installation requirements—such as custom arms, angled plates, or brackets for uneven surfaces.