Electrical enclosures are protective casings designed to house sensitive electronic equipment and electrical components. Their primary purpose is to safeguard internal components such as sensors or…

Electrical enclosures are protective casings designed to house sensitive electronic equipment and electrical components. Their primary purpose is to safeguard internal components such as sensors or PLCs from environmental factors such as moisture, dust, and physical impact. Whether used for control panels, terminal blocks, or PCBs with terminals, the right enclosure type plays a critical role in ensuring safe and efficient electrical connections.

Importance in Various Settings

In both industrial settings and outdoor environments, electrical enclosures offer essential protection. From traffic control systems to remote power supplies, their role in shielding electrical systems from environmental hazards is vital. The use of adaptable box formats and secure termination points ensures a reliable enclosure solution tailored to customer requirements, even in harsh environments or corrosive substances.

Types of Electrical Enclosures

General Multi-Purpose Enclosures

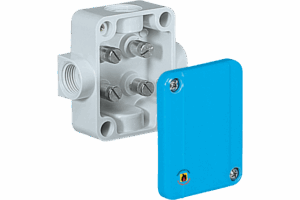

Multi-purpose enclosures are the most common types used across a wide range of applications. These units typically feature a removable cover and cable entry points to facilitate easy installation and maintenance. They support a variety of internal components, from additional wire connections to panel-mounted devices, making them an ideal solution for generic electronic enclosures in both indoor and outdoor applications.

Specific Application Boxes

These enclosures are tailored to meet particular needs in demanding applications. For instance, junction boxes with hinged covers are popular in settings requiring quick access for inspection or rewiring. Their high level of protection and corrosion resistance make them suitable for industrial applications that involve direct contact with harsh elements.

DOLD Distribution Enclosure

DOLD distribution enclosures are designed to meet strict industry standards. With optimized module widths and nominal depth configurations, they provide excellent protection for distribution systems and control panels. Their robust construction ensures durability in both indoor installations and outdoor environments.

Features and Specifications

IP and NEMA Ratings Explained

IP ratings (Ingress Protection) and NEMA ratings define the level of protection an enclosure offers against dust, water, and physical intrusion. An IP66-rated electrical junction box, for instance, ensures total protection against dust and powerful water jets, making it suitable for outdoor enclosures in industrial settings. Understanding these ratings helps match enclosure types with specific electronic equipment and environmental hazards.

Influence of Ratings on Durability and Protection

The higher the rating, the greater the enclosure’s ability to withstand environmental factors such as UV radiation and corrosive substances. Ratings directly impact the enclosure’s long-term durability, especially in outdoor application scenarios. This is particularly crucial for enclosures protecting power supplies or sensitive electrical components in exposed conditions.

Materials Used in Enclosure Construction

Polycarbonate Enclosures

Polycarbonate enclosures provide high impact resistance and clarity, making them ideal for visible monitoring of internal components. They’re commonly used in electronic enclosures requiring durability and protection against UV radiation and corrosion, especially in outdoor applications.

ABS Enclosures

ABS plastic is favored for its lightweight yet rigid properties. These enclosures are well-suited for indoor and mild outdoor environments where protection against dust and moderate impacts is necessary. Their adaptable design supports a range of enclosures for low to medium-voltage electrical systems.

PVC Enclosures

PVC enclosures offer robust resistance to corrosive substances and environmental hazards. They are a reliable choice for junction boxes installed in areas with high exposure to chemicals or moisture. Their excellent insulation and cable entry support make them suitable for complex electrical connections.

Waterproof and Weatherproof Options

IP66-Rated Junction Boxes

These junction boxes provide exceptional sealing for outdoor environments, offering protection against dust ingress and strong water jets. Their high degree of protection makes them a preferred choice for critical electrical equipment used in industrial and construction applications.

Construction Advantages

The design of waterproof enclosures often includes reinforced walls, hinged covers, and advanced gasket systems to maintain a tight seal. This structure ensures longevity and continued protection even under direct contact with rain, humidity, or particulate matter. For demanding applications, these are a go-to enclosure solution.

Industrial and Commercial Applications

Typical Industries Using Enclosures

Electrical enclosures are integral to industries such as manufacturing, automation, utilities, and infrastructure. They house terminal blocks, secure connection wires, and protect control panels in environments exposed to mechanical wear, dust, or temperature fluctuations. In each industrial application, the enclosure’s durability and specification are key factors in maintaining safe operations.

Residential Usage Scenarios

In residential settings, smaller junction boxes and distribution enclosures are used to manage electrical systems safely. These units provide secure termination and facilitate easy maintenance of wiring for lighting, appliances, and networked systems, often with a removable cover for simplified access.

Selecting the Right Enclosure

Assessing Needs and Environments

Choosing the right electrical enclosure involves evaluating the intended environment, required level of protection, and the nature of the electrical components housed within. For outdoor applications, enclosures with UV protection and corrosion resistance are essential. Indoors, ABS plastic options often suffice for less demanding scenarios.

Comparing Features and Specifications

It’s important to match enclosure type to application demands by comparing nominal depth, panel depth, IP/NEMA ratings, and internal layout for components like terminal blocks and cable routing. A well-matched enclosure enhances safety, longevity, and compliance with industry standards.