“Safety Light Curtains: The Ultimate Guide to Industrial Safety Solutions”

Why are safety light curtain essential for industiral automation.

January. 31 2025 | Blog Post, Venus Automation

What Are Safety Light Curtains?

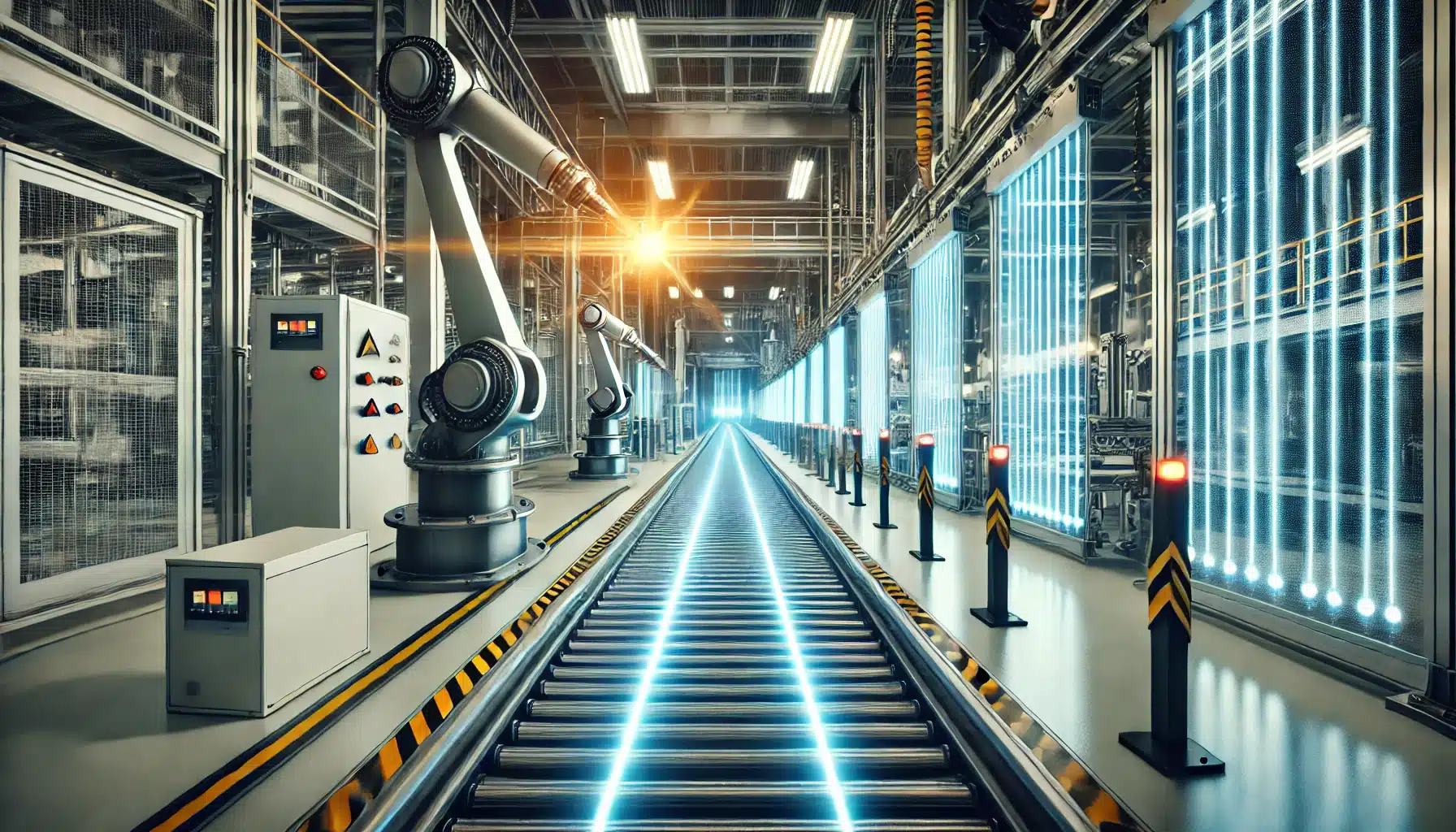

Safety Light curtains in the process industry essentially form a very important part of protection and safeguards to the workpeople from hazardous machinery, without loss of work flow efficiency. These advanced photoelectric safety systems develop an invisible guard of infrared beams that detect intrusions and thus promptly actuate a machine stop to avoid injury. Used widely in manufacturing, robotics, and assembly lines, safety light curtains have become a fundamental element of workplace safety strategies.

How Do Safety Light Curtains Work?

The functionality of safety light curtains relies on their ability to detect interruptions within their sensing field. They include an emitter and a receiver facing each other, forming a protective grid of light beams together. If an object or a person obstructs one of these beams, the system sends a signal to the machine’s control unit to stop the operation in no time. The speed at which it stops reduces injury, which is very effective in dynamic industrial settings where manual interventions are frequent.

Safety light curtains are integrated appropriately with programmable logic controllers or safety relays to institute safety. The system works complementary to ensure that hazardous equipment like presses, cutters, or robotic arms goes to rest once unauthorized entry is detected. Unlike physical barriers that slow down production, light curtains keep areas accessible while offering robust protection; thus, it is a compromise between safety and efficiency in operation.

Key Components of Safety Light Curtains.

Safety light curtains rely on precision components for effective operation. The emitter projects infrared beams in a parallel array while the receiver detects interruptions. Advanced models feature muting sensors, allowing materials to pass without stopping production—crucial for conveyor-based workflows.

These curtains integrate with safety controllers to process signals and enforce protocols. Cascading configurations enable broader coverage, while adjustable resolution settings fine-tune the detection sensitivity. Real-time status updates are available on diagnostic displays to prompt the resolution of issues.

With ever-improving safety regulations and expanding smart manufacturing, safety light curtains improve protection in the workplace without hindering productivity and thus are indispensable to modern industry.

Recent Posts

Benefits of Using safety light curtains in industral automation.

Safety light curtains are an advanced, non-intrusive safeguarding solution for industrial environments that effectively mitigate workplace risks while continuity of operations is maintained. These optoelectronic devices form a very important link in the chain of modern automation, standing out for their seamless approach to accident prevention, productivity enhancement, and regulatory compliance.

Safety light curtains are the light, highly sensitive barriers that instantly stop machinery if an obstruction has been detected. This fast response greatly minimizes the possibility of injury around machinery like robotic arms, presses, and automated conveyors. These safety light curtains do not reduce operational flexibility but allow for the same free space as a solid physical barrier and meet very rigid safety criteria. Their seamless integration enhances a proactive safety culture, reinforcing the dual priority of worker well-being and industrial efficiency. By their very nature, these devices make for a much safer workplace because they remove the unnecessary exposure to moving parts, reducing downtime and liability while optimizing workflow.

Safety integrated, besides increasing productivity, adds to the effectiveness of the work process. Most of the conventional safeguarding methods slow down the operations, whereas safety light curtains allow smooth work processes without interruption. Noncontact operation means that workers can interact with machinery without sacrificing speed or compromising security. Advanced models provide muting that allows controlled passage of materials through them without initiating shutdowns. This ensures that automatic assembly lines, conveyor systems, and robotic workstations achieve maximum throughput with no superfluous stops. The possibility of integrating safety light curtains with programmable logic controllers allows for even finer operational control, enabling responses adapted to the various production situations.

The evolution in industrial safety technologies is continuously developing the functionalities possible with safety light curtains. The emergent trends now include Industry 4.0 and the Industrial Internet of Things, really driving the development of smarter safety solutions with real-time monitoring and predictive maintenance. Modern safety light curtains are designed with data analytics functions that enable operators to assess system performance and predict failures for dynamic adjustment in view of safety. As manufacturing processes continue to be automated, the role of safety light curtains will further grow in securing protection while keeping workplaces highly efficient. Companies using these advanced solutions will position themselves as leaders in industrial safety while attaining maximum compliance and excellence

Understanding with Safety Standards (OSHA, ISO, etc.)

Safety light curtains are crucial for industrial automation as they protect employees from hazardous machinery. With industrial automation becoming advanced, compliance with OSHA and ISO safety standards ensures a very safe workplace.

OSHA specifies the need for machine guarding at 29 CFR 1910.212 and lockout/tag out at 29 CFR 1910.147 to prevent workplace injuries and requires appropriate protection, including light curtains, that can prevent accidental exposure to hazardous equipment.

ISO sets global safety guidelines, particularly ISO 13849 and ISO 12100, on specifying performance levels within safety control systems and the principles of risk assessment. These ensure that safety light curtains meet some industrial reliability and redundancy requirements.

Compliance with OSHA and ISO enhances workplace safety and operational efficiency. Properly implemented safety light curtains reduce accidents, minimize downtimes, and in still a proactive safety culture that helps companies minimize legal and financial risks.

As automation continues to evolve, compliance with OSHA and ISO keeps safeguarding systems both effective and adaptive. By prioritizing safety, industries can avoid injuries and stay compliant to ensure efficient and secure industrial operations.

How to Choose the Right Safety Light Curtain for Your Facility?

Factors to Consider: Resolution, Response Time, and Detection Capability

Other important parameters of a safety light curtain that have to be considered are resolution, response time, and other detection capabilities. The EOS4 X series does give a choice between several resolutions: 14 mm for finger protection and 30 mm for hand protection, it also supply 90 mm for body protection. Generally speaking, the higher the resolution, the greater the detail the item can be detected, making safety on applications with tasks quite intricate much safer. The EOS4 X models offer as much as 6 meters at 14 mm resolution and 20 meters with other models to make sure comprehensive coverage is given in most industrial environments. Built-in, selectable manual/automatic start/restart function and a response time of industry standards enhance the system for reliability and effectiveness.

Type 2 vs. Type 4 Safety Light Curtains: What’s the Difference?

There are some guidelines that will lead through the difference between Type 2 and Type 4 in selecting the right safety light curtain for industrial applications. These classifications have been defined by IEC 61496 for the performance level, fault tolerance, and reliability of the light curtain system.

Type 2 safety light curtains are used in situations with limited risk, where the possibility of serious injury is low. They offer a lower degree of safety integrity: SIL 1, PL c-not by constant monitoring but by periodic checks. They find their application in some basic automation environments where reduced redundancy and fault detection can be afforded.

Type 4 safety light curtains are for applications with the highest risk. The fault tolerance is higher and with increased self-monitoring capabilities. They realize SIL 3, PL e; immediate fault detection and inability to create unsafe conditions. Type 4 would be required for machinery that can inflict catastrophic injury, such as presses and robotic systems, should a failure occur and not be detected.

Choosing between Type 2 and Type 4 depends on risk assessment, required safety levels, and industry regulations to ensure optimal protection and compliance.

ReeR EOS4 (14mm) | SAFETY LIGHT CURTAIN

The ReeR EOS4 X series finger protection safety light curtain is a high-performance industrial safeguarding solution for applications requiring precision and reliability. Engineered for safety and efficiency, it offers 14mm and 30mm resolutions for finger and hand protection, ensuring compliance with ISO 13849 and IEC 61496 standards. Compact design, integrated EDM, and manual/automatic restart options make this device perfectly suitable for integration into a wide range of industrial contexts. The EOS4 X series up to 20 meters operating ranges enable the perfect combination in automation, robotics, and machinery protection. Rugged with fast installation, it reinforces workplace safety without compromising productivity.

| Model Number | Protected Height (mm) | Controlled Height (mm) | Overall Height (mm) |

| EOS4 151X | 160 | 150 | 213 |

| EOS4 301X | 310 | 300 | 363 |

| EOS4 451X | 460 | 450 | 513 |

| EOS4 601X | 610 | 600 | 663 |

| EOS4 751X | 760 | 750 | 813 |

| EOS4 901X | 910 | 900 | 963 |

| EOS4 1051x | 1060 | 1050 | 1113 |

| EOS4 1201X | 1210 | 1200 | 1263 |

| EOS4 1351X | 1360 | 1350 | 1413 |

| EOS4 1501X | 1510 | 1500 | 1563 |

| EOS4 1801X | 1810 | 1800 | 1911 |

ReeR EOS2 (30mm) | SAFETY LIGHT CURTAIN

Industrial automation requires safeguarding to protect personnel from hazardous machinery. The Type 2 EOS2 series from ReeR has a resolution of 30mm, targeting hand protection applications. These devices offer reliable detection capabilities to protect the operator without compromising productivity. Offering compact dimensions of only 30 x 28 mm, EOS2 light curtains come with M12 connectors for easy installation and maintenance. They have the IP65 and IP67 ratings, so they can be used in several industrial conditions. Compliant with SIL 1, SILCL 1, PL c, and Category 2 safety norms, EOS2 series provides reliable performance for Type 2 safety devices. Refer to the following table for protect dimensions.

| Model Number | Protected Height (mm) | Controlled Height (mm) | Overall Height (mm) |

| EOS4 151X | 160 | 150 | 213 |

| EOS4 301X | 310 | 300 | 363 |

| EOS4 451X | 460 | 450 | 513 |

| EOS4 601X | 610 | 600 | 663 |

| EOS4 751X | 760 | 750 | 813 |

| EOS4 901X | 910 | 900 | 963 |

| EOS4 1051x | 1060 | 1050 | 1113 |

| EOS4 1201X | 1210 | 1200 | 1263 |

| EOS4 1351X | 1360 | 1350 | 1413 |

| EOS4 1501X | 1510 | 1500 | 1563 |

| EOS4 1801X | 1810 | 1800 | 1911 |

ReeR EOS4 (30mm) | SAFETY LIGHT CURTAIN

Features and Benefits of ReeR EOS 4 Hand Protection Safety Light Curtain.

The ReeR EOS 4 series is a high-performance safety light curtain engineered for demanding industrial applications that require Type 4, SIL 3, and PL e compliance. It has been designed for hand protection, offering precision, reliability, and easiness of integration in automation contexts where the safeguard of personnel is crucial.

Offering a resolution of 30mm, EOS 4 guarantees correct hand detection with minimum superfluous machine stops. Due to the compact profile, mounting in confined areas is also quite easy, hence making it suitable for a wide range of industrial applications. With IP65 and IP67 protection ratings, EOS 4 resists adverse working conditions, such as dust, water, and vibrations.

By combining self-monitoring with redundant safety circuits, fault detection is ensured in real-time – well before an unsafe condition can occur. A number of applications are possible with the EOS 4 from EDM options to manual/automatic restart selections.

By implementing EOS 4, industries achieve improved operator safety without compromising productivity. The fast response time minimizes downtime, and its high immunity to electromagnetic interference ensures stability in automation-heavy environments. With easy wiring and fast installation, the EOS 4 optimizes machine safety while maintaining the best in operational efficiency and regulatory compliance.

| Product | Protected Height (mm) | Overall Height (mm) |

| EOS4 153X | 160 | 213 |

| EOS4 303X | 310 | 363 |

| EOS4 453X | 460 | 513 |

| EOS4 603X | 610 | 663 |

| EOS4 753X | 760 | 813 |

| EOS4 903X | 910 | 963 |

| EOS4 1053X | 1060 | 1113 |

| EOS4 1203X | 1210 | 1263 |

| EOS4 1353X | 1360 | 1413 |

| EOS4 1503X | 1510 | 1563 |

| EOS4 1803X | 1810 | 1911 |

Vision VX Series:

- Resolution: 30 mm, suitable for hand detection.

- Protected Height: Varies by model, accommodating different safeguarding requirements.

- Operating Range: Up to 20 meters, allowing for flexible installation in diverse environments.

- Safety Level: Complies with Type 4, SIL 3, and PL e standards, ensuring high-level safety integrity.

- Features: Equipped with automatic and manual restart options, external device monitoring (EDM), and high immunity to optical and electromagnetic interference.

Vision VXL Series:

- Resolution: 30 mm, optimized for hand protection.

- Protected Height: Available in various lengths to suit specific application needs.

- Operating Range: Up to 60 meters, ideal for large-scale industrial settings.

- Safety Level: Meets Type 4, SIL 3, and PL e criteria, providing robust safety performance.

- Features: Includes floating blanking, fixed blanking, and reduced resolution capabilities, enhancing adaptability to complex safety scenarios.

Vision MXL Series:

- Resolution: 30 mm, ensuring precise hand detection.

- Protected Height: Customizable to fit various machinery dimensions.

- Operating Range: Up to 8 meters, suitable for medium-range applications.

- Safety Level: Certified to Type 4, SIL 3, and PL e standards, guaranteeing top-tier safety assurance.

- Features: Integrates an advanced muting function for temporary automatic suspension of the safety function during non-hazardous operations, such as material insertion or extraction.

ReeR EOS2 (90mm) | SAFETY LIGHT CURTAIN

The ReeR EOS2 body protection safety light curtain is designed for industrial applications needing Type 2, PL c, and SIL 1 compliance. It protects access and perimeter points while securing personnel and optimizing the workflow.

With long-range detection up to 50 meters, the EOS2 is perfectly designed for guarding large hazardous areas where material flow cannot be obstructed. Its rugged IP65/IP67 enclosure is impervious to dust, water, and industrial contaminants-assuring reliability under demanding conditions.

EOS2 is easily integrated into automated systems with M12 quick-connect cabling and the option for either manual or automatic restart, depending on operating requirements. Advanced optical filtering technology minimizes false triggering from ambient light or EMI, ensuring stability of operation.

Unlike Type 4 curtains, EOS2 offers cost-effective protection for applications where only a moderate level of safety is required, reducing installation and maintenance costs. Its compact form factor of 28mm x 30mm allows installation in space-constrained setups without compromising performance.

For industries related to warehousing, material handling, and automated assembly, EOS2 provides dependable safety compliance with minimum disruption to improve productivity without adding unnecessary system complexity.

Here are the specifications for EOS category 2 body protection safety light curtains. And the ReeR Vision VX series is a range of advanced safety light curtains designed for body protection in industrial environments.

| Product | Protected Height (mm) | Overall Height (mm) |

| EOS4 153X | 160 | 213 |

| EOS4 303X | 310 | 363 |

| EOS4 453X | 460 | 513 |

| EOS4 603X | 610 | 663 |

| EOS4 753X | 760 | 813 |

| EOS4 903X | 910 | 963 |

| EOS4 1053X | 1060 | 1113 |

| EOS4 1203X | 1210 | 1263 |

| EOS4 1353X | 1360 | 1413 |

| EOS4 1503X | 1510 | 1563 |

| EOS4 1803X | 1810 | 1911 |

ReeR EOS4 (90mm) | SAFETY LIGHT CURTAIN

The EOS4 body protection safety light curtain from ReeR represents the completion of harmonization with Type 4, SIL 3, and PL ‘e’, conceived for high-risk industrial settings. It provides very accurate real-time detection, preventing access to dangerous zones and thus safeguarding personnel around hazardous machinery.

The 50mm resolution of the EOS4 works effectively in detecting a person’s presence without false triggering, which is suitable for body detection applications. Compact and with a durable IP65/IP67-rated housing, it works optimally even in areas with dust, wetness, and vibration. This detector features long-range capabilities of up to 20 meters for flexible installation across large workspaces.

The M12 plug-and-play connectors make integration easy, with options for manual or automatic restart functions, to provide flexibility across various industrial systems. Self-diagnostic capabilities are also on-board, allowing the EOS4 to run continuously with the least amount of downtime.

Designed to automate, the EOS4 ensures a safer workplace without sacrificing productivity and, thus, is indispensable in industries where high-level protection is non-negotiable.

| Product | Protected Height (mm) | Overall Height (mm) |

| EOS4 155X | 160 | 213 |

| EOS4 309X | 310 | 363 |

| EOS4 459X | 460 | 513 |

| EOS4 609X | 610 | 663 |

| EOS4 759X | 760 | 813 |

| EOS4 909X | 910 | 963 |

| EOS4 1059X | 1060 | 1113 |

| EOS4 1209X | 1210 | 1263 |

| EOS4 1359X | 1360 | 1413 |

| EOS4 1509X | 1510 | 1563 |

| EOS4 1809X | 1810 | 1863 |

Maintenance and troubleshooting tips for safety light curtains.

Regular Inspection and Cleaning Best Practice

Proper maintenance of safety light curtains is important for their good performance and adherence to standards of safety. Regarding regular inspection, emphasis should be placed on the alignment of sensors, wiring, and deposition of contamination. Ensure the emitter and receiver are mounted properly without any source of vibration that could misalign the beams. Test for correct functioning to see whether the proper time is used and if the light curtain indicates obstructions just as expected.

Cleaning with lint-free cloths and using non-abrasive cleaning agents will help prevent damage to the optical surfaces. Avoid the use of solvents that may degrade the protective coatings. If operating in a high-dust environment or one prone to moisture, the installation of protective covers can help protect components from debris accumulation. Periodic validation of Safety Outputs and Control Integration ensures the system interacts appropriately with emergency stop mechanisms and automation controls

Common Issues and How to Fix Them

Among the most common faults, one finds misalignment, which generally arises due to mechanical shocks or vibrations. Realignment requires the recalibration of mounting brackets with confirmation of the operating range and angular tolerance by the manufacturer between emitter and receiver.

It minimizes false causes from ambient light, reflecting surfaces, and electromagnetic noise via adjustment in sensitivity settings, polarized filters, or by repositioning light sources around. If the penetration of the beam is poor because the lenses are dirty or greased up, clean them and make sure the field of sense is clear of obstruction.

Damage in wiring-be it in cables or loose connections-can result in intermittent failures. Perform continuity tests, looking at connectors for corrosion or wear. If the safety light curtain does not reset, use the diagnostic interface for fault codes according to muting and override conditions in automated workflows.

Proactive maintenance and swift troubleshooting minimize downtime and enhance safety compliance, ensuring protection uninterruptedly in manufacturing and industrial automation environments.