Servo Amplifiers for Precision Motion Control Servo amplifiers are essential components in industrial automation, responsible for controlling servo motors with high accuracy and responsiveness. Whether…

Servo Amplifiers for Precision Motion Control

Servo amplifiers are essential components in industrial automation, responsible for controlling servo motors with high accuracy and responsiveness. Whether you’re operating a simple conveyor or a multi-axis robotic system, choosing the right servo drive ensures efficiency, precision, and system stability. Our Mitsubishi Electric servo amplifier range combines cutting-edge technology with proven reliability, making it a top choice for a wide range of automation needs.

1. Types of Servo Amplifiers

AC Servo Amplifiers

Designed for AC servo motors, these amplifiers offer high performance, reliability, and are suitable for complex motion control tasks. The Mitsubishi MR-J5 series is a premium AC servo amplifier designed for ultra-fast response and real-time adjustment.

DC Servo Amplifiers

Used with DC servo motors, these amplifiers offer straightforward control in systems requiring low-speed, high-torque applications. While less common in modern systems, they are still relevant in specialized industrial equipment.

Digital Servo Amplifiers

Digital amplifiers offer precise control through advanced signal processing and support for fieldbus communication. Mitsubishi’s digital servo amplifiers provide seamless integration with EtherCAT, CC-Link IE TSN, and other modern automation networks.

Analog Servo Amplifiers

Analog models use continuous signals and are typically used in older or simpler systems. While lacking the sophistication of digital types, they are reliable and easy to configure for basic applications.

2. Benefits of Servo Amplifiers (Why Choose Mitsubishi?)

- Precision & Speed: Mitsubishi servo amplifiers offer ultra-fast response times and high-resolution feedback for accurate motion control.

- Energy Efficiency: Regenerative braking and energy-saving modes reduce power consumption.

- Advanced Tuning: Built-in auto-tuning and vibration suppression features simplify commissioning.

- Scalability: From single-axis systems to complex multi-axis setups, Mitsubishi’s servo drives fit all levels of automation.

- Reliability: Backed by Mitsubishi Electric’s decades of engineering, these drives are designed for long life in tough environments.

3. Key Features of Mitsubishi Servo Amplifiers

- Real-time communication via CC-Link IE TSN / EtherCAT / SSCNET

- Support for absolute and incremental encoders

- Built-in vibration suppression and machine diagnosis tools

- Multi-axis synchronization capabilities

- Auto-gain tuning and load-adaptive control

- Compact design with DIN rail mounting options

- Integrated safety functions (STO, SS1, etc.)

4. Applications and Use Cases

- Robotics: Smooth and coordinated joint movement with high repeatability

- Packaging Machinery: High-speed and precise product handling

- Conveyors and Material Handling: Accurate start-stop control with torque management

- CNC Machinery: Stable and precise multi-axis machining

- Pick-and-Place Automation: Fast cycle times with reduced jitter

- Printing and Textile Equipment: Speed and tension control with precise registration

5. Technical Specifications and Comparison Table

| Model | Power Range | Communication | Encoder Support | Vibration Suppression | Safety Features |

|---|---|---|---|---|---|

| MR-J5-G | 0.1–3.0 kW | CC-Link IE TSN | Absolute/Incremental | Yes | STO, SS1 |

| MR-J5W2 | Dual-axis 0.2–1.5 kW | CC-Link IE TSN | Absolute/Incremental | Yes | STO |

| MR-JET | 0.1–2.0 kW | Modbus / Pulse Train | Incremental | Basic | STO |

| MR-J4 | 0.1–55 kW | SSCNET III/H | Absolute/Incremental | Yes | STO, SS1, SS2 |

Note: Availability may vary by region.

6. FAQ – Servo Amplifiers

What does a servo amplifier do?

A servo amplifier supplies controlled electrical power to a servo motor based on input commands and feedback signals. It ensures the motor responds accurately to changes in position, speed, or torque, making it essential for precise motion control in industrial automation.

What is the difference between AC and DC servo amplifiers?

AC servo amplifiers are designed for use with AC servo motors and are commonly used in modern, high-speed applications. DC servo amplifiers, on the other hand, work with DC motors and are typically found in legacy systems or low-speed, high-torque applications.

Why choose Mitsubishi servo amplifiers?

Mitsubishi servo amplifiers offer advanced tuning capabilities, high-speed communication, and robust safety features. They are engineered for seamless integration with Mitsubishi PLCs and HMIs, delivering exceptional performance and reliability in complex automation environments.

Are Mitsubishi servo drives compatible with other servo motors?

Mitsubishi servo amplifiers are optimized for use with Mitsubishi servo motors. While some generic compatibility may exist, using the full Mitsubishi servo system ensures maximum performance, communication accuracy, and access to all advanced features.

What industries use servo amplifiers?

Servo amplifiers are widely used in robotics, packaging, CNC machinery, electronics manufacturing, printing, textile machines, and automotive production—anywhere high-precision motion control is needed.

What is a Servo Drive and Servo Motor?

Servo and motion control systems are essential for high-precision automation, enabling accurate positioning, speed control, and synchronization in industrial applications. These systems ensure smooth, efficient, and reliable motion, enhancing productivity and performance across various industries.

Key Features:

- High-Speed & Precision Control: Ensures accurate positioning and smooth operation.

- Advanced Feedback Mechanisms: Uses encoders and sensors for real-time adjustments.

- Flexible Communication: Supports multiple protocols for seamless integration.

- Scalability: Adaptable for applications from single-axis to multi-axis control.

- Energy Efficiency: Optimized motor control reduces power consumption.

Applications:

- Industrial Automation: Robotics, conveyors, and pick-and-place systems.

- CNC Machinery: Precision machining, cutting, and milling operations.

- Packaging & Material Handling: High-speed sorting, labeling, and assembly lines.

- Medical & Laboratory Equipment: Accurate control for imaging, diagnostics, and testing devices.

Servo and motion control systems enhance accuracy, speed, and reliability, making them crucial for modern automation and high-performance machinery.

Frequently Asked Questions

1. What is the purpose of the servo system?

A servo system is designed to deliver high-precision control over position, speed, and torque in motion control applications. Used widely in industrial automation, servo systems ensure that machinery operates with exact movements. In the case of the Mitsubishi servo system, advanced servo motors and high-speed servo amplifiers offer seamless integration with factory automation, supporting everything from robotic arms to high-speed packaging lines.

2. Servo Motors vs. Servo Amplifiers

A servo motor generates controlled motion, while a servo amplifier (or drive) powers and regulates the motor using feedback from sensors. Together, they form the core of any servo system. Mitsubishi’s servo range, such as the MR-J5 series, offers advanced amplifiers that work in sync with high-resolution motors to deliver fast, responsive, and accurate control for complex automation tasks.

3. What is the main difference between a standard motor and a servo?

Unlike standard motors that run at a fixed speed, servo motors are built for precision and feedback-driven control. A servo system constantly adjusts the motor’s position and speed based on real-time data. With Mitsubishi servo motors, this capability is taken further using built-in encoders and intelligent servo amplifiers for ultra-precise industrial motion control.

4. How long do servo drives last?

Most servo amplifiers, including those from Mitsubishi Electric, have a typical lifespan of 10–20 years, depending on the operating environment and maintenance. Mitsubishi’s servo drives are known for their reliability and durability in demanding industrial conditions, especially when paired with compatible automation equipment like MELSEC PLCs.

5. How powerful is a servo motor?

Servo motors come in a variety of power ratings, from compact 50W models to high-powered industrial units delivering tens of kilowatts. Mitsubishi servo motors offer scalable power options suitable for lightweight pick-and-place systems up to heavy-duty machine tools and gantries, all while maintaining exceptional speed and control.

6. Why is it called servo?

The term “servo” comes from the Latin servus, meaning “to serve,” reflecting how these systems automatically adjust to reach a desired output. A servo system continuously monitors feedback and corrects its movements—precisely what Mitsubishi’s servo solutions are designed to do in modern factory automation.

7. What would you use a servo for?

Servo systems are used wherever precise motion control is required—such as in robotics, conveyors, CNC machines, and assembly lines. Mitsubishi servo motors are especially popular in industries like electronics, automotive, food & beverage, and packaging, where speed and precision are mission-critical.

8. What is the advantage of servo?

The key advantage of a servo system is its ability to offer high-speed, high-accuracy motion control with real-time responsiveness. Mitsubishi servo systems go further with features like absolute positioning, vibration suppression, and easy integration with their PLCs and HMIs—making them ideal for smart factories and Industry 4.0 setups.

9. What are the disadvantages of a servo?

While servo motors and drives offer incredible performance, they can be more expensive than basic motor systems and may require careful setup and tuning. However, Mitsubishi’s servo range simplifies commissioning with auto-tuning features and easy-to-use software tools—helping reduce engineering time and increase ROI.

At Venus Automation, we specialise in delivering high-performance servo motors and servo amplifiers tailored for demanding industrial environments. Featuring advanced technology from Mitsubishi Electric, our range of servo motors, servo amplifiers, and PLCs are built to power automation, robotics, CNC, and smart manufacturing systems. Whether you need high-torque performance, precise control, or seamless integration with PLCs, our servo solutions provide the speed control, accuracy, and reliability your applications demand.

Understanding Servo Systems

A servo system is much more than a basic motor—it’s an intelligent, feedback-driven control loop that brings machines to life with precise and dynamic movement. By combining Mitsubishi servo motors, servo amplifiers, and high-resolution encoders, these systems regulate motion with exceptional responsiveness.

Used in electric motors, automation lines, packaging machines, and robotics, servo systems deliver consistent results across a wide variety of industries. Whether you’re in food & beverage, pharmaceutical manufacturing, materials handling, or automotive assembly, Mitsubishi servos ensure efficiency and precision.

Definition and Components

A complete servo system includes a type of motor (like AC servo motors, DC servo motors, or Brushless Servo Motors), a servo amplifier, feedback devices such as Absolute encoders, and a motor controller. Mitsubishi’s MELSERVO platform integrates these seamlessly.

Key Functions and Applications

Servos perform critical functions like:

- Torque and speed control

- Accurate position feedback and speed feedback

- Smooth linear motion or rotary actuation through a drive shaft or output shaft

Applications span industrial servomotors, Integrated servomotors, robotics, and Linear Servo Motors, with Mitsubishi’s solutions trusted in Modern servomotors and automation setups.

Servo Motor Fundamentals

Mitsubishi servo motors offer dynamic response, high torque output, and low electrical noise, making them ideal for high-speed, high-precision applications. With built-in control circuitry and robust software control options, these motors are built to handle rigorous power requirements.

How Servo Motors Work

A servo motor receives a control input from a controller and adjusts its position using encoder data. This creates a closed-loop control system that dynamically adjusts power and feedback.

Differences Between Servo Motors and Stepper Motors

Stepper motors are a common type used in basic systems, but lack position feedback. Closed-loop stepper motors and closed loop stepper systems try to bridge this gap, yet Brushless DC and Brushless Servo Motors remain superior in terms of maximum torque, responsiveness, and safe torque delivery.

Common Applications of Servo Motors

Typical applications include:

- CNC machines in metal fabrication

- Robotic pick-and-place in electronics assembly

- High-speed labeling in packaging

- Conveyor tracking in logistics

- Precision dosing and filling in pharmaceuticals

- Automated palletizing in food and beverage production

Servo Amplifier Basics

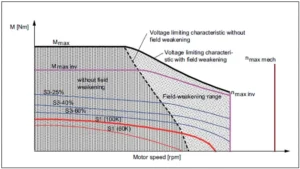

Servo amplifiers regulate power between the controller and the motor. Mitsubishi’s MELSERVO-J4 series delivers high-resolution response and built-in digital drives.

Function and Importance of Servo Amplifiers

Amplifiers adjust current to match load demands and power source quality. They connect directly to the connector to power and factor in current consumption, avoiding spikes in consumption under max load.

Differences Between Servo Drives and Servo Amplifiers

Though terms often overlap, analog servo drives refer to legacy systems. Newer Tuning Free Servo Motors and Tuning Free Servo Motor Drivers simplify setup and offer better output torque tuning.

Applications of Servo Amplifiers

- Robotics and automated gantries

- Servo-controlled tools in branch of power electronics

- Integration with dedicated servo drivers, servo controller units, and controller circuits

Feedback Mechanisms in Servo Systems

Accurate motion relies on encoder feedback. Mitsubishi motors include Absolute encoders, high-end encoder types, and support torque limit settings based on system loads.

Role of Encoders

Encoders measure motor shaft rotation, reporting back via control signal wires. High-end systems even adjust torque output in real time.

Importance of Precise Control and Positioning

Thanks to position at power, systems hold their place during startup. This ensures accuracy, especially in environments with electrical noise or fluctuating power supply.

Integration with Microcontrollers

While industrial setups use PLCs, basic demonstration setups may integrate simple servos with Arduino or Raspberry Pi to simulate servo behaviors. These help illustrate the inherent benefits of Mitsubishi’s industrial-grade servos.

Using Servos with Arduino

Prototype systems may test movement logic and control options using control input and voltage regulators, but real-world deployment relies on robust systems from Venus Automation.

Practical Examples and Circuits

Examples include simulating packaging processes or demonstrating tracking movement in lab automation—use cases that scale up seamlessly using our Mitsubishi servo range.

Industrial Applications

Servos power modern industry—enabling accuracy, speed, and dependability across production lines.

Servo Systems in Industrial Automation

From metal fabrication, robotics in electronics, and packaging machinery, to pharmaceutical dispensing and food processing, Mitsubishi servo motors and servo amplifiers are designed for performance and reliability.

Case Studies: MELSERVO-J4 in Action

Our solutions have supported:

- Multi-axis CNC and robotic automation in automotive manufacturing

- High-speed, multi-head packaging machines in the food industry

- Hygienic motion control for pharmaceutical and medical device production

Advanced Servo Technologies

Servo innovation goes beyond motion—it’s about smart, adaptable systems.

Electrical Considerations in Servos

Account for:

- Proper power supply and correct power supply ratings

- Low current- consumption

- Use of reliable energy sources and protected cabling

Servo Systems in Entertainment and Robotics

Servos are also used in industrial-grade automation for advanced robotics and motion systems.

Broader integration with Safety & Automation Systems

In modern industrial environments, Servo Amplifiers are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Role in Industrial Robotics

In robotics, servo motors and servo amplifiers enable smooth motion and endurance under continuous operation. Whether for OEM builders or large-scale manufacturing, Venus Automation delivers motion with intelligence.

Need help finding the correct servo for your application? Contact Venus Automation for expert advice on selecting the right servo motor, servo amplifier, and accessories for your powerful motor application.