1

Whats the Difference? Safety Relays vs Safety PLCs.

SAFETY RELAYS and Safety PLCs

An introduction to Relays and Plcs

In industrial workplaces, safety relays and safety PLCs are crucial for preventing accidents and ensuring employee safety. Safety relays manage safety-critical inputs and outputs, like emergency stop buttons, to stop machinery when hazards are detected. These devices are vital in industries such as manufacturing and automotive. Safety systems, including controllers, relays, and sensors, protect workers and machinery by monitoring safety functions and ensuring compliance with standards. The samos® PRO, with its intuitive samos® PLAN 6 software, and MOSAIC safety controllers, known for their expandable and modular design, are key solutions for managing multiple safety functions and enhancing safety control systems.

Key differences and features

The primary difference between a safety relay and a safety PLC lies in their complexity and functionality. Safety relays are simpler, electromechanical devices designed for specific safety functions, such as emergency stops or guard monitoring, and are well-suited for straightforward, single or two-step safety applications. In contrast, safety PLCs are more advanced and programmable, capable of handling complex safety tasks by using redundant microprocessors, which eliminate the need for multiple safety relays. Safety PLCs are ideal for applications requiring integrated and flexible safety solutions across multiple machines or processes.

Functionality | Simple devices for opening/closing circuits

Complexity | Suitable for basic control tasks

Programming | No programming required

Scalability | Limited scalability; each relay performs a specific function

Diagnostics | Minimal diagnostics, typically visual indicators

Applications | Used for simple on/off control, e.g., lighting or motor starting

Costs | Generally, less expensive

Additional Features

Safety Relays

- Emergency Stop Monitoring: Safety relays can monitor emergency stop buttons to ensure machinery stops immediately when needed.

- Safety Gate Monitoring: They can monitor the status of safety gates and interlocks, ensuring that machinery operates only when gates are closed.

- Two-Hand Control: Some safety relays are designed to require two-hand operation, which is essential for certain machinery to prevent accidental activation.

- Cross Monitoring: This feature ensures that both channels of a dual-channel safety system are functioning correctly and are not short-circuited.

- Automatic and Manual Start/Restart: Safety relays can be configured for automatic or manual start/restart, depending on the safety requirements of the application.

- Time Delays: Some relays include time delay functions for controlled stopping of machinery.

- Feedback Loop Monitoring: This ensures that external contactors or relays are functioning correctly and are in the expected state.

- Force-Guided Contacts: These ensure that the contacts move together, providing a reliable indication of the relay’s status.

- LED Indicators: Many safety relays have LED indicators for easy status monitoring and diagnostics.

Safety PLCs

- Programmability: Safety PLCs can be programmed to handle a wide range of safety tasks, allowing for customization to specific application needs.

- Redundancy: They often include redundant microprocessors to ensure reliability and prevent failures.

- Integrated Safety Functions: Safety PLCs can manage multiple safety functions, such as emergency stops, safety gate monitoring, and speed control, within a single system.

- Modular Design: Many safety PLCs are modular, allowing for expansion with additional input/output modules to accommodate larger or more complex systems.

- Communication Interfaces: They typically support various communication protocols for integration with other systems and devices, facilitating data exchange and remote monitoring.

- Diagnostic Capabilities: Safety PLCs provide detailed diagnostics and status information, which helps in troubleshooting and maintaining the system.

- Compliance with Safety Standards: They are designed to meet international safety standards, ensuring that they provide a high level of safety assurance.

- User-Friendly Software: Programming and configuration are often done through intuitive software interfaces, which may include features like drag-and-drop programming and simulation tools.

High-Speed Processing: Safety PLCs are capable of processing safety functions quickly to ensure rapid response to unsafe conditions.

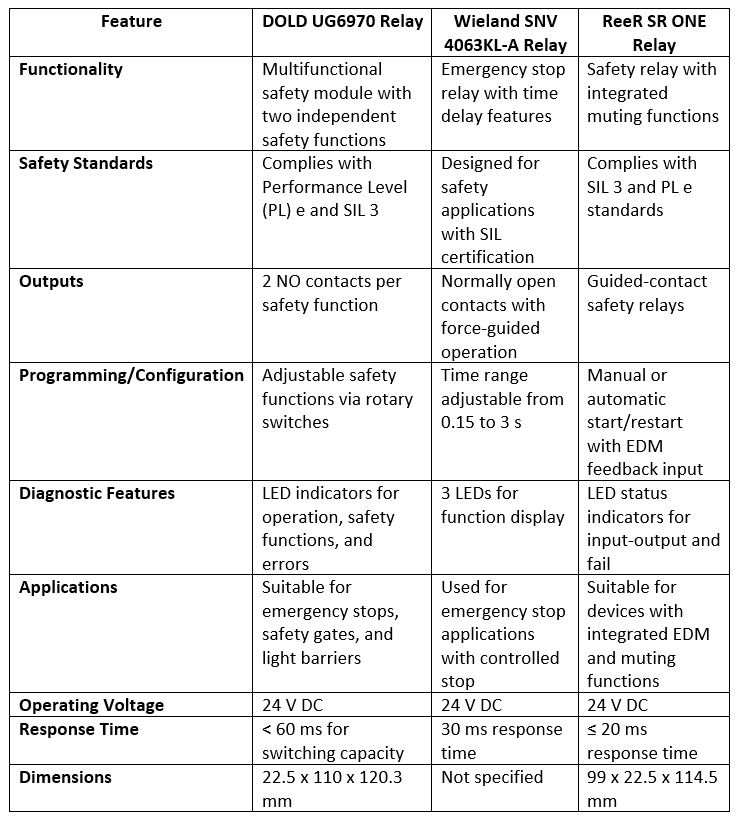

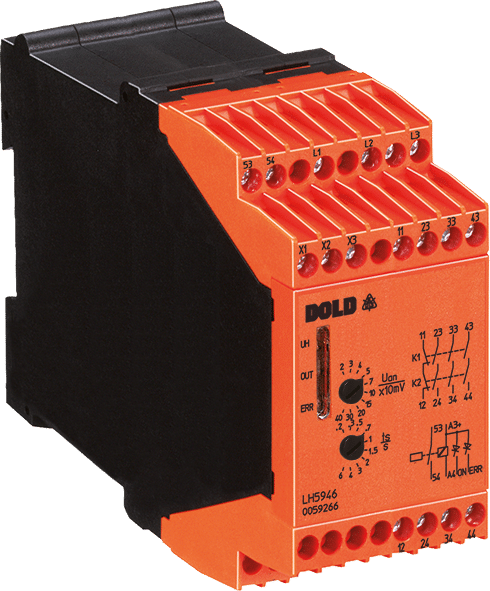

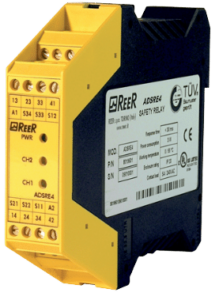

Safety Relays (DOLD vs Wieland vs ReeR)

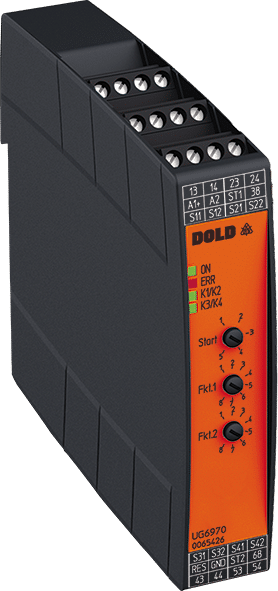

At Venus, we offer a range of different safety relays from DOLD, Wieland and ReeR. The DOLD UG6970 is a multifunctional safety module suitable for emergency stops, safety gates, and light curtains, complying with PL e and SIL 3 standards, and featuring adjustable safety functions with LED diagnostics. The Wieland SNV 4063KL-A is an emergency stop relay with time delay capabilities, designed for controlled stops with SIL certification, offering force-guided contacts and adjustable time ranges. The ReeR SR ONE is a safety relay with integrated muting functions, ideal for devices needing manual or automatic start/restart with EDM feedback, meeting SIL 3 and PL e standards, and providing LED status indicators. Other types of safety relay include time-delay relays, speed-monitoring relays, standstill monitoring and timer relays, PCB relays and relay expansion modules. Also available are type-specific control relays, like the safety edge relay, light curtains relay, or two-hand control relay. Each relay addresses specific safety needs, enhancing control in industrial applications.

| Part Number | Supply Voltage | Contacts | Item Number |

| UF 6925.02 | 24 V DC | 2 NO Contacts | 0068316 |

| UF 6925.22 | 24 V DC | 2 NO + 1 NC Contacts | 0067558 |

| UF 6925.03 | 24 V DC | 3 NO | 0067556 |

| Part Number | Supply Voltage | Contacts | Item Number |

| UG 6970.04 | 24 V DC | 2 NO Contacts | 0065426 |

| Model | Product Number | Article Number | Supply Voltage | Number of Outputs |

| Dold – Control Unit | BH 5911.22 | 055532 | DC 24 V | 2 NO contacts, 1 NC contact |

| BH 5911.3 | 055531 | DC 24 V | 3 NO contacts |

3 NO Contacts

| Part Number | Ordering Code | Supply Voltage | Terminals | Outputs |

| SNA 4043K-A | R1.188.1810.0 | 24 V AC/DC | Screw Terminals | 3NO+1NC, 230VAC 6A |

| SNA 4043K-A | R1.188.1830.0 | 115-120 V AC | Screw Terminals | 3NO+1NC, 230VAC 6A |

| SNA 4043K-A | R1.188.1840.0 | 230 V AC | Screw Terminals | 3NO+1NC, 230VAC 6A |

| SNA 4043K-C | R1.188.1940.0 | 24 V AC/DC | Push-in Terminals | 3NO+1NC, 230VAC 6A |

| SNO 4043K-C | R1.188.5000.0 | 230 V AC | Push-in Terminals | 3NO+1NC, 230VAC 6A |

| SNA 4043KM-A | R1.188.3250.0 | 24 V AC/DC | Screw Terminals | 3NO+1NC, 230VAC 6A |

| SNA 4043KE-A | R1.188.3810.0 | 24 V AC/DC | Screw Terminals | 3NO+1NC, 230VAC 6A |

| SNA 4043KE-C | R1.188.3820.0 | 24 V AC/DC | Push-in Terminals | 3NO+1NC, 230VAC 6A |

4 NO Contacts

| Part Number | Ordering Code | Supply Voltage | Terminals | Outputs |

| SNA 4044K-A | R1.188.1860.0 | 24 V AC/DC | Screw Terminals | 4NO+1NC, 230VAC 6A |

| R1.188.1880.0 | 115-120V AC | Screw Terminals | 4NO+1NC, 230VAC 6A | |

| R1.188.1890.0 | 230 V AC | Screw Terminals | 4NO+1NC, 230VAC 6A | |

| SNA 4044K-C | R1.188.1960.0 | 24 V AC/DC | Push-in Terminals | 4NO+1NC, 230VAC 6A |

| SNA 4044KM-A | R1.188.1480.0 | 24 V AC/DC | Screw Terminals | 4NO+1NC, 230VAC 6A |

| SNA 4044KM-C | R1.188.3410.0 | 24 V AC/DC | Push-in Terminals | 4NO+1NC, 230VAC 6A |

| Model | Time range | Product Number | Supply Voltage | Terminals |

| SNE 4004K | – | R1.188.0590.0 | 24 VDC | Screw Terminals |

| SNE 4004K-C | – | R1.188.1980.0 | 24 VDC | Push-in Terminals |

| SNE 4004KV-A | 0.5s | R1.188.0460.0 | 24 VDC | Screw Terminals |

| 1s | R1.188.0470.0 | 24 VDC | Screw Terminals | |

| 2s | R1.188.0480.0 | 24 VDC | Screw Terminals | |

| 3s | R1.188.0490.0 | 24 VDC | Screw Terminals | |

| SNE 4004KV-C | 0.5s | R1.188.2410.0 | 24 VDC | Push-in Terminals |

| 1s | R1.188.2420.0 | 24 VDC | Push-in Terminals | |

| 2s | R1.188.2430.0 | 24 VDC | Push-in Terminals | |

| 3s | R1.188.2440.0 | 24 VDC | Push-in Terminals |

2 NO Contacts

| Part Number | Ordering Code | Terminals | Supply Voltage | Outputs | Safety Applications |

| SNO 4062K-A | R1.188.0700.2 | Screw Terminals | 24V AC/DC | 2NO+1NC, 230VAC 6A | E-Stop, Safety Gate, Light curtains |

| SNO 4062KM-A | R1.188.0720.2 | Screw Terminals | 24V AC/DC | 2NO+1NC, 230VAC 6A | E-Stop, Safety Gate, Light curtains |

| SNO 4062K-C | R1.188.2000.0 | Push-in Terminals | 24V AC/DC | 2NO+1NC, 230VAC 6A | E-Stop, Safety Gate, Light curtains |

3 NO Contacts

| Part Number | Ordering Code | Supply Voltage | Synchr. Time | Terminals |

| SNO 4083KM-A | R1.188.3580.0 | 24 V DC | 1.5 s | Screw Terminals |

| SNO 4083KM-A | R1.188.3590.0 | 115-120V AC | 1.5 s | Screw Terminals |

| SNO 4083KM-C | R1.188.3600.0 | 24 V DC | 1.5 s | Push-in Terminals |

| SNO 4083KM-C | R1.188.3610.0 | 115-120V AC | 1.5 s | Push-in Terminals |

| SNO 4083KM-A | R1.188.3840.0 | 24 V DC | 0.5 s | Screw Terminals |

| SNO 4083KM-A | R1.188.3830.0 | 115-120V AC | 0.5 s | Screw Terminals |

| SNO 4083KM-C | R1.188.3850.0 | 24 V DC | 0.5 s | Push-in Terminals |

| SNO 4083KM-C | R1.188.3860.0 | 115-120V AC | 0.5 s | Push-in Terminals |

| Model | Product Number | Contacts | Outputs | Operating Voltage | Adjustment Range | Terminals |

|---|---|---|---|---|---|---|

| SNS 4084K-A | R1.188.3640.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.5 – 99Hz | Screw Terminals |

| SNS 4084K-C | R1.188.3650.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.5 – 99Hz | Push-in Terminals |

| SNS 4074K-A | R1.188.3620.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.1 – 9.9Hz | Screw Terminals |

| SNS 4074K-C | R1.188.3630.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.1 – 9.9Hz | Push-in Terminals |

| SNS 4084K-A | R1.188.3480.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.5 – 99Hz | Screw Terminals |

| SNS 4084K-C | R1.188.3490.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.5 – 99Hz | Push-in Terminals |

| SNS 4084K-A | R1.188.3660.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.1 – 9.9Hz | Screw Terminals |

| SNS 4084K-C | R1.188.3670.0 | 4 Inputs | 4 Safe OSSD outputs and 2 OSSD outputs | 24 VDC | 0.1 – 9.9Hz | Push-in Terminals |

| Part Number | Ordering Code | Supply Voltage | Terminals |

| SNT 4M63K-A | R1.188.1050.0 | 24 V AC/DC | Screw Terminals |

| R1.188.1060.0 | 115-120V AC | Screw Terminals | |

| R1.188.1070.0 | 230 V AC | Screw Terminals | |

| SNT 4M63K-C | R1.188.2390.0 | 24 V AC/DC | Push-in Terminals |

| Part Number | Ordering Code | Outputs | Terminals | Supply Voltage |

| SNV4063KL-A | R1.188.0620.0 | 2NO, 1NO Off-delay 0.15-3 seconds, 230VAC 6A | Screw Terminal | 24VDC |

| R1.188.0640.0 | 2NO, 1NO Off-delay 1.5-30 seconds, 230VAC 6A | Screw Terminal | 24VDC | |

| R1.188.4100.0 | 2NO, 1NO Off-delay 7.5-150 seconds, 230VAC 6A | Screw Terminal | 24VDC | |

| SNV4063KL-C | R1.188.2010.0 | 2NO, 1NO Off-delay 0.15-3 seconds, 230VAC 6A | Push-in Terminal | 24VDC |

| R1.188.3900.0 | 2NO, 1NO Off-delay 1.5-30 seconds, 230VAC 6A | Push-in Terminal | 24VDC |

| Part Number | Order Code | Terminals | Supply Voltage |

| SNZ 4052K-A | R1.188.0530.1 | Screw Terminal | 24 AC/DC |

| R1.188.0940.1 | Screw Terminal | 115 – 120 AC | |

| R1.188.0950.1 | Screw Terminal | 230 V AC | |

| SNZ 4052K-C | R1.188.2020.0 | Push-in Terminal | 24 AC/DC |

| Part Number | Order Code | Contacts |

| AD SR0 | 1330902 | 2 NO + 1NC (2A at 250 VAC) |

| AD SR0A | 1330903 | 2 NO (2A at 250 VAC) |

| Part Number | Order Code | Category | Terminals | Contacts |

| AD SRE4 | 1330913 | Cat. 4 | Screw Terminal | 3 NO +1 NC (5A at 250 VAC) |

| AD SRE4C | 1330914 | Cat. 4 | Clamp Terminal | 3 NO +1 NC (5A at 250 VAC) |

| AD SRE3 | 1330911 | Cat. 3 | Screw Terminal | 2 NO (6A at 250 VAC) |

| AD SRE3C | 1330912 | Cat. 3 | Clamp Terminal | 2 NO (6A at 250 VAC) |

| Part Number | Order Code | Terminals | Contacts |

| AD SRT | 1330915 | Screw Terminal | 2 NO (6A at 250 VAC) |

| Part Number | Order Code | Start/Restart | Terminals | Contacts |

| SR E4 | 1330803 | Either Automatic or Manual | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR E4 C | 1330808 | Either Automatic or Manual | Clamp Terminal | 2 NO (6A at 250 VAC) |

| SR E4C | 1330804 | Manual Only | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR E4C C | 1330809 | Manual Only | Clamp Terminal | 2 NO (6A at 250 VAC) |

| Part Number | Order Code | Description | Terminals | Contacts |

| SR ONE | 1330900 | Safety Interface for Safety Light Curtains | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR ONE C | 1330811 | Safety Interface for Safety Light Curtains | Clamp Terminal | 2 NO (6A at 250 VAC) |

| SR ONE M | 1330904 | Safety Interface for Safety Light Curtains, with Integrated Muting Functions | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR ONE MC | 1330812 | Safety Interface for Safety Light Curtains, with Integrated Muting Functions | Clamp Terminal | 2 NO (6A at 250 VAC) |

| Part Number | Order Code | Description | Terminals | Contacts |

| SR SELECT | 1330941 | Multifunction safety interface | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR SELECT C | 1330813 | Multifunction safety interface | Clamp Terminal | 2 NO (6A at 250 VAC) |

| Part Number | Order Code | Terminals | Contacts |

| SR T | 1330805 | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR TC | 1330810 | Clamp Terminal | 2 NO (6A at 250 VAC) |

| Part Number | Order Code | Description | Terminals | Contacts |

| SR X | 1201710 | Safety Interface for Cat. 2 safety photocells | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR XC | 1201714 | Safety Interface for Cat. 2 safety photocells | Clamp Terminal | 2 NO (6A at 250 VAC) |

| SR XM | 1201711 | Safety Interface for Cat. 2 safety photocells, with integrated Muting functions | Screw Terminal | 2 NO (6A at 250 VAC) |

| SR XMC | 1201715 | Safety Interface for Cat. 2 safety photocells, with integrated Muting functions | Clamp Terminal | 2 NO (6A at 250 VAC) |

Featured Products

Our Product Range

Both safety relays and safety PLCs play essential roles in maintaining safe and efficient industrial operations. While safety relays provide reliable and straightforward solutions for specific safety tasks, safety PLCs offer flexibility and advanced control for complex safety requirements. Together, they form a comprehensive safety framework that protects workers, machinery, and the environment, ensuring compliance with safety standards and enhancing overall operational efficiency. As industries continue to evolve, the integration of these safety technologies will remain crucial in fostering safe and productive workplaces. Click the products below to view the offered products at Venus!

Click to view our Safety Relay product Range

Click to view our Safety PLC product Range

What does the PLC or Relay receive? – Safety Input Device Range

The effectiveness of any safety system, regardless of choice of PLC or relay, begins with its ability to detect hazards and trigger appropriate protective responses. As such, safety input products form the foundation of a reliable safety architecture. Selecting the correct components to match specific hazards is essential for maintaining workplace safety.

Venus Automation offers a wide range of safety input devices to suit varied industrial applications. Detection solutions include the safety light curtain range, available for body protection, hand protection, and finger protection. Options supporting long range sensing and outdoor environments are available, along with muting light curtain models designed for automated processes. Supporting components such as photo cells, connection boxes, and muting accessories are also supplied. Additional detection options include multi beam systems and advanced laser scanner technologies.

To detect presence or motion at close range, proximity sensors are available, including non-contact switches, with magnetic or RFID coding technologies. Enclosures come in plastic, metal, or stainless steel variants for application-specific durability.

Mechanical safety detection is supported by products such as safety edge and mounting systems, contact mats, and bumpers with relevant edge accessories. These are ideal for perimeter and surface-triggered protection zones. For advanced zone control, trapped key systems and blocking devices ensure process integrity.

Manual control inputs are also critical in many safety scenarios. Venus Automation provides safety enabling switches, limit switch options, foot pedal switches, control pads, and standard control components.

Together, these input systems interface with the machine’s transmission system, ensuring rapid response to unsafe conditions. Combined with suitable outputs and logic control, they serve as the first line of defence in safeguarding personnel and equipment.

Conclusion

Choosing between a safety relay and a safety PLC depends on the complexity of the application and safety requirements. For straightforward, single-function safety measures like emergency stop monitoring, safety relays offer a simple and cost-effective solution. However, when managing multiple safety functions across interconnected machinery, programmable safety controllers such as the samos® PRO or MOSAIC safety controller provide greater flexibility, scalability, and diagnostics.

While traditional relays are reliable, industries increasingly lean towards integrated safety PLCs for their ability to streamline complex safety processes and reduce wiring. Both solutions play an essential role in industrial safety, ensuring compliance with stringent regulations and protecting workers and equipment. Selecting the right system involves balancing cost, expandability, and ease of implementation. Whether opting for modular safety relays or advanced programmable logic controllers, implementing a well-designed safety system is crucial to fostering a safe and efficient workplace.