Emergency Stop (E-Stop) relays are essential safety devices used to trigger an immediate shutdown of machinery in critical situations. These relays play a pivotal role…

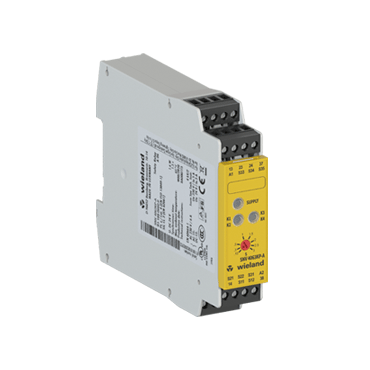

Emergency Stop (E-Stop) relays are essential safety devices used to trigger an immediate shutdown of machinery in critical situations. These relays play a pivotal role in industrial safety systems by monitoring and controlling emergency stop functions to prevent accidents. By integrating E-Stop relays into your safety circuit, you can ensure compliance with safety requirements and achieve a higher safety integrity level across various applications.

Importance of E-STOP Relays in Industrial Safety

In modern industrial environments, E-Stop relays are indispensable. They provide rapid disconnection of hazardous machine movements and initiate emergency shutdowns in the event of danger. Their compatibility with safety gates, light curtains, and other safety input devices allows for flexible, wide-ranging safety solutions. Incorporating high-quality safety relays ensures safe operation and supports safety functions across production lines and automation systems.

Key Features of E-STOP Relays

Maximum Functionality in Minimal Widths

E-Stop safety relays are engineered for compact installations without compromising on performance. Their slim design allows for optimal use of control cabinet space, while still offering a full suite of safety functions—ranging from safety inputs monitoring to emergency stop functions.

Efficient Hazardous Area Protection

Designed for enhanced safety in hazardous zones, E-Stop relays work seamlessly with safety input devices like light barriers and safety gates. These modules maintain control over the supply voltage and monitor safety contacts to detect faults or disconnections, ensuring continuous, safe operation even in challenging environments.

Rapid Problem-Solving for Simple Applications

For simpler machine architectures, E-Stop relays offer quick deployment and easy integration. Whether it’s an emergency stop button or a two-hand control setup, these relays simplify wiring and configuration while delivering maximum safety with minimal complexity.

Broader integration with Safety & Automation Systems

Emergency Stop Relays are a critical core of modern safety systems, but are only one part of an integrated architecture. These components will inevitably work in tandem with other critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are also key elements, managed by the logic structure of either a safety relay or safety PLC.

Advanced installations frequently incorporate safety non-contact switches, RFID switches, mechanical interlock switches, and/or solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Applications of E-STOP Relays

Use with Safety Gates

E-Stop relays integrated with safety gates help monitor open/close positions and ensure machine power is disconnected when gates are not securely closed. This is critical for protecting operators during maintenance or setup tasks.

Light Barriers Applications

In environments where access needs to be monitored without physical guards, light curtains and light barriers work alongside E-Stop relays to secure zones. The relay receives signals from safety devices and triggers immediate responses when beams are interrupted.

Integration with Contact Expansion Modules

When more safety contacts are needed, contact expansion modules can be added to E-Stop relays. This expands their capabilities and allows coverage of multiple safety zones, while maintaining a single point of control for emergency shutdowns.

Overview of Different Safety Relay Modules

E-STOP/Safety Gate Time Delay Relays

These modules are designed for applications requiring delayed disengagement of safety outputs. They are ideal for processes that must complete a specific sequence before halting, supporting both E-Stop and safety gate functions with configurable delay times.

Safety Mat & Edge Relays

Used in conjunction with pressure-sensitive safety devices, these relays detect force or presence on mats and edges to stop hazardous movements. They ensure safety functions are executed instantly upon detection.

Multifunction Safety Relays

Multifunction relays support a wide range of safety applications—from safety inputs like emergency stop buttons to two-hand control and light curtains. Their flexibility makes them suitable for diverse industrial safety systems requiring reliable and scalable solutions.

Advantages of Safety Relays

Ensuring Emergency Safety

E-Stop safety relays are critical for guaranteeing immediate response during hazardous events. They activate emergency stop functions to prevent injury and equipment damage, contributing to maximum safety in all operations.

Enhancing Operational Safety

By continuously monitoring safety contacts and input devices, safety control relays help maintain stable and secure machine operation. This ensures compliance with safety requirements and boosts overall productivity.

Meeting Future Safety Standards

High-quality safety relays are built to align with evolving safety standards and protocols. Their design supports advanced diagnostics, enhanced safety integration, and compatibility with safety integrity level (SIL) frameworks.

Differentiation Between Various Safety Relay Types

Analyzing Key Characteristics

Different types of safety relays vary in their number of safety inputs, supported functions, and reaction times. Some focus on emergency stop circuits, while others support complex safety devices like two-hand controls and safety modules. Understanding these differences helps in selecting the right fit for your system.

Selecting the Right Safety Relay for Specific Needs

Choosing the correct relay depends on the required safety function, the number of signals from safety devices, and integration with other safety components. E-Stop relays, for example, are best suited for rapid shutdowns, while multifunction relays offer broader capabilities in one unit.

Essential Characteristics for Implementation

Key implementation factors include supply voltage compatibility, number of safety contacts, mounting options, and diagnostic feedback. A successful safety relay setup requires evaluating these aspects based on the industrial environment, expected safety level, and connected safety input devices.

Conclusion and Market Insights

E-Stop relays are foundational elements of industrial safety systems. As demands for enhanced safety and compliance grow, the market continues to evolve with compact, intelligent, and multifunctional relay modules. Investing in a wide range of safety relays—from emergency stop buttons to advanced safety modules—ensures long-term protection, operational stability, and regulatory alignment for modern manufacturing.