22

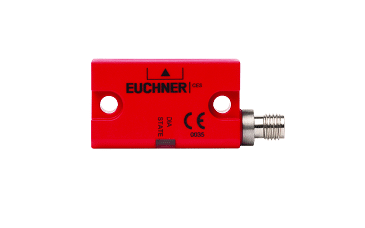

Locked In And Switched On: Euchner CES Devices

Safeguarding machinery – Euchner’s Interlocking Innovation

Maintaining safety in an industrial environment is critical; and modern strategies and technologies must be adopted to protect workers from hazards, and protect machinery from malfunction and failure. To do so, strict safety protocols for both workers and machinery must be undertaken through the deployment of sophisticated safety systems.

Ensuring industrial safety requires advanced solutions that seamlessly integrate with machinery to prevent unauthorized access, detect hazards, and minimize operational risks. Among the most effective technologies for safeguarding both workers and equipment are Euchner CES Devices, which utilize RFID-based safety switching to deliver precise and reliable protection. These cutting-edge safety systems provide highly secure access control while ensuring that machines remain locked until safe conditions are met.

One of the key innovations in this range is the Transponder Coded Read Head, which offers non-contact safety monitoring, ensuring that safety doors and enclosures remain securely locked until all risks are mitigated. Similarly, the RFID Safety Switch delivers highly tamper-proof protection, making it an ideal choice for safeguarding hazardous zones where mechanical switches may not provide adequate security.

For environments requiring advanced authentication and monitoring, the CES Evaluation Units integrate seamlessly with these safety switches, providing comprehensive access control and diagnostics. Additionally, the Inductive Coding RFID Safety Switch enhances security with unique coding, ensuring that only authorized access is granted to sensitive machine areas.

By implementing Euchner CES safety devices, industries can achieve superior safety standards while maintaining operational efficiency, reinforcing a proactive approach to industrial risk management.

Euchner’s CES series of transponder-coded safety systems exemplify steps taken to upkeep safe machine operation, using RFID technology to monitor the status of safety guards, doors, and other protective barriers. Euchner’s CES safety switches and read heads work in tandem to ensure that industrial machinery operates only when it is safe to do so, preventing accidents upon unauthorised/unsafe behaviour surrounding the machinery.

In environments such as automated manufacturing lines, Euchner’s transponder-coded switches are vital in preventing injuries by stopping machine operations when safety conditions are not met. These devices prove their value in settings that require precise control over access to hazardous areas; thus providing a reliable worker safety solution to prevent accidents.

WHAT is a CES?

A Coding Electronic System (CES) refers to a type of transponder-coded safety system used for high-security safety applications. They are non-contact, thus not requiring components to touch to trigger variances in inputs/outputs. A CES is comprised of three components:

1. Actuators (transponders) – coded keys or tags containing unique RFID codes, they are attached to the moving part of a guard, door or gate.

2. Read heads (sensors) – mount to the fixed part or guard of the machine. They read in the RFID code of the actuator once it comes into proximity.

3. Evaluation units – process the signals from the read heads and determine if the safety conditions are met. In Euchner’s CES series of automation safety, the evaluation unit and read heads are integrated into one assembly – which is often referred to as a safety switch.

Key overview of the CES system:

Purpose and Function

The CES series from Euchner intend to aid in the upkeep of safety in industrial applications. This particularly applies to moving parts surrounding powered machinery, such as the guards human-operated machines. Furthermore, the CES series can also be used in the environments within and around automated machinery. By placing CES switches on guards and gates, and relating them to the safe operating conditions of machinery, the states of these CES switches can thus enable/disable the ability for the machinery to remain/turn on.

Applications

CES transponder-coded systems enhance industrial safety by ensuring that machinery operates only when safety guards, doors, or barriers are securely closed. These systems use Radio Frequency Identification (RFID) codes to prevent unauthorised access and unsafe operation. In guards onboard machinery or high-risk zones surrounding those machines, Euchner’s switches provide repeatedly reliable protection by controlling access to the operation of these machines, and compliance with safety standards.

features

The CES transponder-coded safety systems are non-contact interlock systems for machine safeguarding solutions. They feature RF technology, with two semi-conductor outputs to allow for redundancy in their design; and are monitored using evaluation units to enable for a dynamic, self-checking system. The system’s unique RFID signals ensures a high level of security, thus reducing the chances for unsafe use or unauthorised ‘tricking’ of the system. CES series units operate on 24V DC, ensuring its compatibility with standard industrial power supplies.

integration

CES devices comprise modular safety switches and sensors, and thus support the connection of switches and read heads to one another to allow for custom variations. This customisation enables Euchner to offer a holistic solution for a safety switching system. Euchner offer a variety of shapes and sizes of their read heads and switches, and the provisions for both guard-locked and non-guard-locked switches, Euchner’s CES series can thus be integrated into a variety of systems that call for safeguarding of moving parts.

The CES series from Euchner intend to aid in the upkeep of safety in industrial applications. This particularly applies to moving parts surrounding powered machinery, such as the guards human-operated machines. Furthermore, the CES series can also be used in the environments within and around automated machinery. By placing CES switches on guards and gates, and relating them to the safe operating conditions of machinery, the states of these CES switches can thus enable/disable the ability for the machinery to remain/turn on.

CES transponder-coded systems enhance industrial safety by ensuring that machinery operates only when safety guards, doors, or barriers are securely closed. These systems use Radio Frequency Identification (RFID) codes to prevent unauthorised access and unsafe operation. In guards onboard machinery or high-risk zones surrounding those machines, Euchner’s switches provide repeatedly reliable protection by controlling access to the operation of these machines, and compliance with safety standards.

The CES transponder-coded safety systems are non-contact interlock systems for machine safeguarding solutions. They feature RF technology, with two semi-conductor outputs to allow for redundancy in their design; and are monitored using evaluation units to enable for a dynamic, self-checking system. The system’s unique RFID signals ensures a high level of security, thus reducing the chances for unsafe use or unauthorised ‘tricking’ of the system. CES series units operate on 24V DC, ensuring its compatibility with standard industrial power supplies.

CES devices comprise modular safety switches and sensors, and thus support the connection of switches and read heads to one another to allow for custom variations. This customisation enables Euchner to offer a holistic solution for a safety switching system. Euchner offer a variety of shapes and sizes of their read heads and switches, and the provisions for both guard-locked and non-guard-locked switches, Euchner’s CES series can thus be integrated into a variety of systems that call for safeguarding of moving parts.

applications and functions

CES systems are integral to machine guarding applications, ensuring that safety doors, gates, and protective coverings for machinery are secured in the correct position before the machine can operate.

CES help to prevent accidental access to dangerous areas, thereby protecting workers from serious injuries. In industries dealing with hazardous materials or high-energy processes, CES are employed to controlled access to critical areas.

Instances of use of a CES can be seen widely in packaging and assembly lines, where the status of safety interlocks on automated machinery is monitored. By verifying that all guards and doors are properly closed, a CES can prevent the machinery from starting if any risk of exposure to moving parts is present.

CES systems are integral to machine guarding applications, ensuring that safety doors, gates, and protective coverings for machinery are secured in the correct position before the machine can operate.

CES help to prevent accidental access to dangerous areas, thereby protecting workers from serious injuries. In industries dealing with hazardous materials or high-energy processes, CES are employed to controlled access to critical areas.

Instances of use of a CES can be seen widely in packaging and assembly lines, where the status of safety interlocks on automated machinery is monitored. By verifying that all guards and doors are properly closed, a CES can prevent the machinery from starting if any risk of exposure to moving parts is present.

Euchner’s CES transponder-coded system provides key benefits by ensuring machinery only operates when guards and barriers are securely closed. It enhances safety through RFID technology; preventing unauthorised access, and will instantly halt machine function if safety conditions are not met. Rather than previous interlock methods which employed electromagnetic actuators and sensors which allowed for only particular mounting and directions of approach, the RF technology present in the CES allows for any direction of approach, and various degrees of mounting.

key benefits of the CES EuCHNER system

Description:

CES-AR series of switches can be connected with up to 20 switches in series, and up to 12 of these switches can be monitored. Thus, in a system with multiple gates, the ability to monitor these gates becomes a powerful tool in ensuring all doors are closed.

Description:

Some of Euchner’s safety switches, such as the CET line, feature guard locking, in which switches are able to lock into place unless certain requirements are met; such as button inputs or RFID sensing. These can maintain up to 6500 Newtons of locking force. The unique RFID signals required along with the high locking force allow for both physical and electronic guards against unsafe operation or misuse.

Description:

CES products like the CES-A-LNA-SC and CES-I-AP/AR can be mounted in various orientations. The CES family come in varying sizes and offer actuation in one, three, or five axes.

Description:

Euchners switches include 2 semiconductor outputs per item, allowing for redundant and therefore safer circuitry. Most CES systems meet Category 4 safety with one switch per door, and regardless of mounting, will continue to pass these requirements. By only requiring one switch per door, this reduces wiring and mounting costs. All CES products are rated with an IP67 protection rating, being fully protected from dust, debris, short-term immersion in water.

Description:

DSP technology facilitates the integration of laser systems with other digital and automated systems, enabling advanced automation and control in industrial and scientific settings. Guard-locking switches such as the CET-AS offers integration/communication with external interface software, and feature LEDs for detailed diagnostics and troubleshooting.

Description:

CES-AR series of switches can be connected with up to 20 switches in series, and up to 12 of these switches can be monitored. Thus, in a system with multiple gates, the ability to monitor these gates becomes a powerful tool in ensuring all doors are closed.

Description:

Some of Euchner’s safety switches, such as the CET line, feature guard locking, in which switches are able to lock into place unless certain requirements are met; such as button inputs or RFID sensing. These can maintain up to 6500 Newtons of locking force. The unique RFID signals required along with the high locking force allow for both physical and electronic guards against unsafe operation or misuse.

Description:

CES products like the CES-A-LNA-SC and CES-I-AP/AR can be mounted in various orientations. The CES family come in varying sizes and offer actuation in one, three, or five axes.

Description:

Euchners switches include 2 semiconductor outputs per item, allowing for redundant and therefore safer circuitry. Most CES systems meet Category 4 safety with one switch per door, and regardless of mounting, will continue to pass these requirements. By only requiring one switch per door, this reduces wiring and mounting costs. All CES products are rated with an IP67 protection rating, being fully protected from dust, debris, short-term immersion in water.

Description:

DSP technology facilitates the integration of laser systems with other digital and automated systems, enabling advanced automation and control in industrial and scientific settings. Guard-locking switches such as the CET-AS offers integration/communication with external interface software, and feature LEDs for detailed diagnostics and troubleshooting.

offered products

Beyond Interlocks: Exploring the Full Spectrum of Safety Inputs

While Euchner’s CES systems offer robust protection through intelligent interlocking, they represent just one layer of a complete safety strategy.

Venus Automation offers a wide range of safety input devices to suit varied industrial applications. Detection solutions include the safety light curtain range, available for body protection, hand protection, and finger protection. Options supporting long range sensing and outdoor environments are available, along with muting light curtain models designed for automated processes. Supporting components such as photo cells, connection boxes, and muting accessories are also stocked. Additional detection options include multi beam systems and advanced laser scanner technologies.

To detect presence or motion at close range, proximity sensors are available, including non-contact switches, with magnetic, RFID, or stainless-steel technologies. Enclosures come in plastic, metal, or stainless-steel body variants for application-specific durability.

Mechanical safety detection is supported by products such as safety edge and mounting systems, contact mats, and bumpers with relevant edge accessories. These are ideal for perimeter and surface-triggered protection zones. For advanced zone control, trapped key systems and blocking devices ensure process integrity.

Manual control inputs are also critical in many safety scenarios. Venus Automation provides safety enabling switches, limit switch options, foot pedal switches, control pads, and standard control components.

Together, these input systems interface with the machine’s transmission system, ensuring rapid response to unsafe conditions. Combined with suitable outputs and logic control, they serve as the first line of defence in safeguarding personnel and equipment.

Click to view our products