13

MOSAIC SAFETY CONTROLLERS: IT’S DOUBLE OR NOTHING

Overview of MOSAIC Safety PLC:

WHAT classifies as mosaic safety controllers?

In industrial automation, efficiency and safety must go hand in hand. As machinery and processes become more complex, ensuring a secure working environment while maintaining operational flexibility is a top priority. This is where MOSAIC Safety Controllers come into play, offering an advanced and scalable solution for managing multiple safety functions within a single system. Designed to streamline safety operations, MOSAIC controllers eliminate the need for multiple safety relays, reducing wiring, installation time, and overall system complexity.

Unlike traditional safety devices that require individual configurations, MOSAIC safety controllers provide centralized control, making it easier to monitor, adapt, and expand safety applications across multiple machines. Their modular design allows for seamless integration with a variety of safety components, ensuring adaptability in dynamic industrial settings. Whether used in automotive manufacturing, robotics, or high-speed production lines, these controllers enhance both compliance and efficiency, ensuring that safety is never compromised.

By integrating multiple safety functions into one cohesive system, MOSAIC controllers offer a future-proof solution for businesses looking to optimize their industrial safety strategy. With enhanced diagnostics, flexible programming, and a cost-effective approach, these controllers are redefining the way industries approach machine safety.

MOSAIC safety controller typically refers to a system or device used in industrial automation or safety-critical environments to monitor and ensure the safety of operations involving machines or processes. MOSAIC safety controllers are considered a unique safety device due to its ability to control and manage multiple safety functions for single or multiple machines simultaneously.

This function can be attributed to ability to be easily expandable, configured and modular design. MOSAIC expansion units are components designed to extend the capabilities of MOSAIC safety PLCs (Programmable Logic Controllers). These expansion units provide additional inputs and outputs (I/O) to the base MOSAIC PLC, allowing for more complex and larger-scale safety control systems.

Key features of MOSAIC systems:

PURPOSE AND FUNCTION

A MOSAIC safety controller is designed to execute various safety functions such as emergency stop, light curtains, safety gates, and safety interlocks. These functions ensure that personnel and equipment are protected from potential hazards.

INTEGRATION

It integrates with other industrial control systems (such as PLCs – Programmable Logic Controllers) to coordinate safety-related activities with operational tasks. This integration allows for seamless control and monitoring of safety measures across the entire system.

APPLICATIONS

Manufacturing/ Food Processing – MOSAIC systems are used to monitor safety devices like emergency stops, light curtains, and safety mats, and to control the safety functions of machinery. They help prevent accidental machine starts, reduce risks during setup and maintenance, and stop operations when a hazard is detected.

Automation Industry – MOSAIC systems help manage multiple safety inputs like emergency stops, safety scanners, and door locks, ensuring the safe shutdown of machinery and robots in case of any hazards.

COMPLIANCE AND STANDARDS

MOSAIC safety controllers adhere to international safety standards such as ISO 13849, IEC 61508 and AS4023.2019. These standards define the requirements for the design, implementation, and validation of safety-related systems to ensure reliability and effectiveness in safeguarding personnel and assets.

PROGRAMMING AND CONFIGURATION

MOSAIC safety controllers typically have user-friendly programming interfaces or software tools for configuring safety functions, defining safety zones, and setting parameters related to safety performance.

SYSTEM DIAGNOSIS

Fault Tolerance: They often incorporate features for fault tolerance and diagnostic capabilities to detect and respond to faults or failures within the safety system promptly.

Monitoring and Reporting: They provide real-time monitoring of safety conditions and may generate reports or alerts in case of safety breaches or anomalies. This helps in maintaining a high level of safety awareness and operational efficiency.

Scalability: Depending on the application, MOSAIC safety controllers may need to support scalability, allowing for expansion or modification of safety functions as operational requirements change.

A MOSAIC safety controller is designed to execute various safety functions such as emergency stop, light curtains, safety gates, and safety interlocks. These functions ensure that personnel and equipment are protected from potential hazards.

It integrates with other industrial control systems (such as PLCs – Programmable Logic Controllers) to coordinate safety-related activities with operational tasks. This integration allows for seamless control and monitoring of safety measures across the entire system.

Manufacturing/ Food Processing – MOSAIC systems are used to monitor safety devices like emergency stops, light curtains, and safety mats, and to control the safety functions of machinery. They help prevent accidental machine starts, reduce risks during setup and maintenance, and stop operations when a hazard is detected.

Automation Industry – MOSAIC systems help manage multiple safety inputs like emergency stops, safety scanners, and door locks, ensuring the safe shutdown of machinery and robots in case of any hazards.

MOSAIC safety controllers adhere to international safety standards such as ISO 13849, IEC 61508 and AS4023.2019. These standards define the requirements for the design, implementation, and validation of safety-related systems to ensure reliability and effectiveness in safeguarding personnel and assets.

MOSAIC safety controllers typically have user-friendly programming interfaces or software tools for configuring safety functions, defining safety zones, and setting parameters related to safety performance.

Fault Tolerance: They often incorporate features for fault tolerance and diagnostic capabilities to detect and respond to faults or failures within the safety system promptly.

Monitoring and Reporting: They provide real-time monitoring of safety conditions and may generate reports or alerts in case of safety breaches or anomalies. This helps in maintaining a high level of safety awareness and operational efficiency.

Scalability: Depending on the application, MOSAIC safety controllers may need to support scalability, allowing for expansion or modification of safety functions as operational requirements change.

mosaic safety designer (MSD) SOftware:

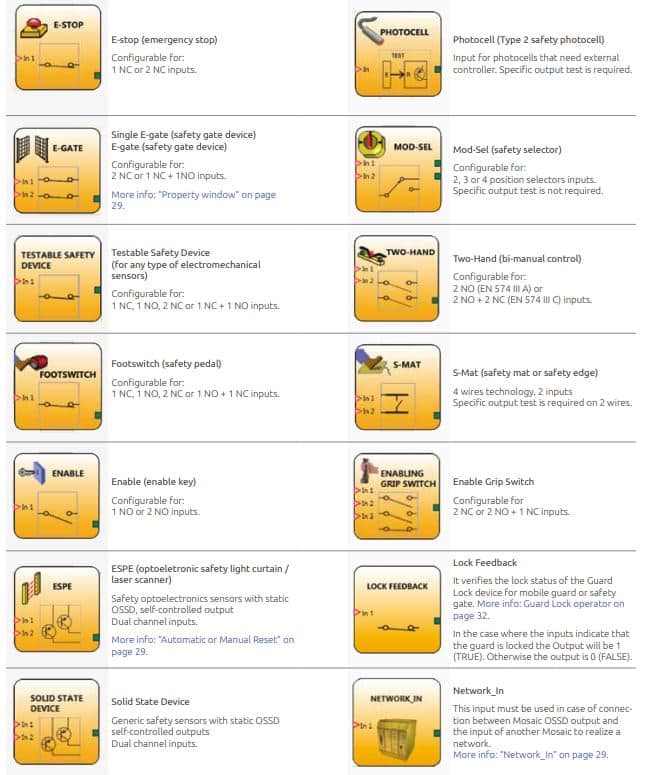

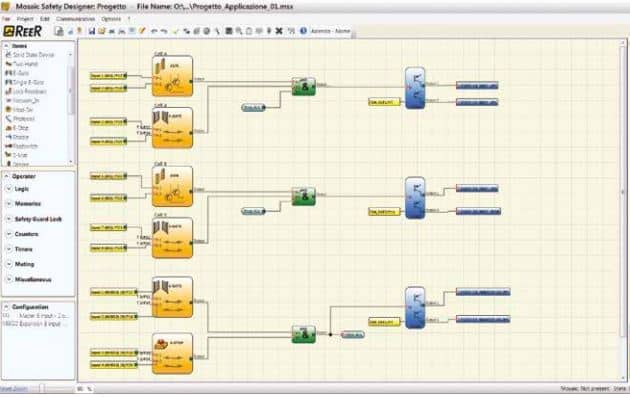

The MOSAIC safety relays come with a complementary software from ReeR used for configuring the safety relays and designing complex systems and then simulating the output which will be integral for faultless safety system. The ReeR Safety Designer software is designed to be easy to use and full of functional blocks that contain different safety equipment to be flexible with designing a wide range of safety systems. Furthermore, the I/O monitor allows for monitoring of all I/O’s of any designed safety system in real-time.

The flexibility and simplicity of the designing complex safety systems can be attributed to the different available terminal blocks for a range of safety devices found in the MOSAIC Safety Designer.

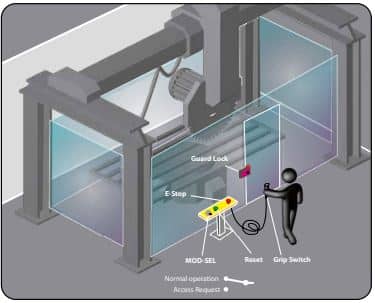

operational Scenario: Guard lock System

This is a safety feature that physically locks the door or access point to a hazardous area when the associated machinery is operating at normal speed. This prevents unauthorized access and ensures safety during operation.

Normal Operation: Access to the hazardous area is restricted while the machinery is running at normal speed. The guard lock remains locked.

End of Cycle or Access Request: Access is permitted either after the machine’s working cycle is complete or when the operator switches a selector (MOD SEL) to “Access Request”.

Tool Stop: When the machine stops, the guard lock is automatically unlocked, allowing the door to be opened to access the hazardous area. The speed controller verifies that the tool is indeed stopped (zero speed).

Maintenance Mode: To perform maintenance, the operator switches the MOD SEL to “Maintenance”. Once the machine stops, the guard lock unlocks to allow access. If the machine needs to operate at reduced speed for maintenance purposes while someone is inside, a Grip Switch allows this under strict speed monitoring. If speed exceeds a defined threshold or if the Grip Switch is released, the machine stops immediately.

Emergency Stop (E-stop): This button is available on the operator panel to immediately stop the machine in case of an emergency.

Reset Button: After an emergency stop or any intervention requiring the guard lock to be released, the reset button restores normal operating conditions of the safety lock system.

This is a safety feature that physically locks the door or access point to a hazardous area when the associated machinery is operating at normal speed. This prevents unauthorized access and ensures safety during operation.

Normal Operation: Access to the hazardous area is restricted while the machinery is running at normal speed. The guard lock remains locked.

End of Cycle or Access Request: Access is permitted either after the machine’s working cycle is complete or when the operator switches a selector (MOD SEL) to “Access Request”.

Tool Stop: When the machine stops, the guard lock is automatically unlocked, allowing the door to be opened to access the hazardous area. The speed controller verifies that the tool is indeed stopped (zero speed).

Maintenance Mode: To perform maintenance, the operator switches the MOD SEL to “Maintenance”. Once the machine stops, the guard lock unlocks to allow access. If the machine needs to operate at reduced speed for maintenance purposes while someone is inside, a Grip Switch allows this under strict speed monitoring. If speed exceeds a defined threshold or if the Grip Switch is released, the machine stops immediately.

Emergency Stop (E-stop): This button is available on the operator panel to immediately stop the machine in case of an emergency.

Reset Button: After an emergency stop or any intervention requiring the guard lock to be released, the reset button restores normal operating conditions of the safety lock system.

Operational Sequence:

During normal operation, the guard lock remains engaged while the machine runs at standard speed, restricting access to the hazardous area until the machine stops naturally or the MOD SEL switch is activated. In maintenance mode, set via the MOD SEL switch, the guard lock automatically unlocks once the machine stops. If the machine must operate at reduced speed during maintenance with personnel in the hazardous area, the Grip Switch permits this under monitored conditions. The operator panel features emergency stop and reset buttons for immediate halting of operations and for restoring normal operations after safety interventions.

Reer mosaic safety controllers

ReeR MOSAIC safety controller is a modular and programmable system designed to manage the safety of machines and processes in industrial environments. It is highly flexible and can be customized to suit various safety applications by integrating different safety devices like emergency stops, light curtains, and safety gates.

Here at Venus Automation, the most commonly sold safety controller are:

- MOSAIC M1 – Equipped with 8 safety inputs, 2 independent programmable dual-channel safety outputs (OSSD), and 2 SIL 1/PL c outputs.

- MOSAIC M1S – Features 8 safety inputs, 4 independent programmable single-channel safety outputs (OSSD), and the capacity for up to 4 SIL 1/PL c outputs

- MOSAIC M1S COM – Combines 8 safety inputs, 4 independent programmable single-channel safety outputs (OSSD), up to 4 SIL 1/PL c outputs, and enhanced communication features by connection via an ethernet cable

MOSAIC safety expansion units are modular devices that extend the functionality and capacity of the MOSAIC safety controller system. These expansion units allow the system to manage additional safety inputs, outputs, and specialized functions, enabling it to handle more complex safety applications.

- MI8O2 – 8 inputs, 4 test outputs, 2 OSSD pairs with EDM and Start/Restart interlock, 2 signal outputs

- MI8O4 – 8 inputs, 4 test outputs, 4 single OSSD (or 2 pairs) with EDM and Start/Restart interlock, 4 signal outputs

- MO4 – 4 OSSD pairs with EDM and Start/Restart interlock, 4 signal outputs

MVO expansion modules for speed monitoring are designed to extend the capabilities of speed control systems, particularly in applications where precise monitoring of motor speed and position is critical for safety and efficiency. These modules are commonly used in industrial automation to ensure that motors and other moving parts are operating within safe speed limits, preventing hazards like overspeed or standstill.

The MVO is the most requested expansions module for speed monitoring at Venus Automation

ReeR MOSAIC Fieldbus modules are essential for Industry 4.0, enabling seamless communication between safety devices and controllers in real time. Supporting multiple protocols like PROFIBUS, PROFINET, EtherNet/IP, and CANopen, these modules facilitate efficient data exchange and centralized safety control. They simplify integration in smart factories, automating processes and enhancing safety in manufacturing and logistics. By connecting various components, they help maintain optimal machine performance and respond quickly to safety events, making them crucial for modern, interconnected industrial environments.

Here at Venus Automation, the ReeR MOSAIC – Fieldbus MBP is a house-hold staple.

From Centralized Safety Logic to Field-Level Action: A Complete Output Strategy

While MOSAIC Safety Controllers excel at managing and streamlining multiple safety functions within a single system, the real-world effectiveness of any safety strategy depends on how well those decisions are executed at the field level.

A key component in modern safety execution is the safety PLC. These programmable devices allow custom safety logic, with flexible input/output terminal assignments. Venus Automation offers a variety of models, including the MOSAIC PLC from Reer, Samos PLC from Wieland, and GEMNIS PLC from Pizzato—each delivering advanced and reliable safety functionality.

Where complex programmability is unnecessary, alternative options such as the safety relay range are available. This includes standalone relays, time-delay relay, speed-monitoring relay, standstill monitoring and timer, PCB relay, relay expansion modules, and control relays like the emergency stop relay, safety edge relay, light curtains relay, and two-hand control relay. These options provide effective and application-specific safety responses.

Essential manual inputs such as the emergency stop remain integral to any safety architecture, despite lacking an automatic safety input. Venus Automation supplies complete solutions including emergency stop accessories, pushbuttons, two-hand stops, and specialized devices like the rope pull emergency stop. For modern installations, wireless safety systems, including wireless emergency stop units, remote controls and accessories, are also available.

Critical integration elements such as contact blocks are supplied to ensure seamless circuit connections. Additional safety monitoring components include the safety encoder, which monitors motor speed, and interlock devices such as tongue solenoid interlock switch and electro-magnetic switches. For more complex safety guarding, multifunctional gatebox units provide a consolidated interface, easily mounted on protective enclosures like concertina guards.

Access restriction and control can also be achieved through electronic key systems, ensuring machinery operates only under authorized conditions. Finally, for output-side protection, safety contactors and pneumatic safety valve solutions are available to ensure reliable machine stoppage when hazardous conditions are detected.

Click to view our products