RFID Safety Switches What Are RFID Switches? Definition and Basic Functionality RFID switches are electronic, non-contact safety devices that use Radio Frequency Identification (RFID) technology…

RFID Safety Switches

What Are RFID Switches?

Definition and Basic Functionality

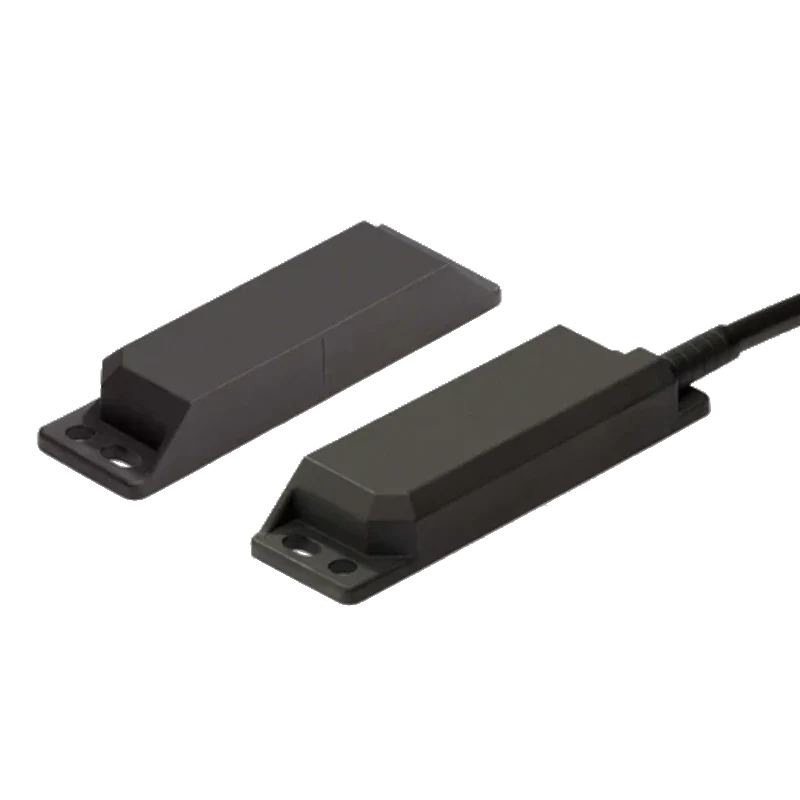

RFID switches are electronic, non-contact safety devices that use Radio Frequency Identification (RFID) technology to detect the presence of an actuator and control access to machines or safeguarded areas. Unlike mechanical or magnetic switches, RFID switches provide a coded, tamper-resistant link between the sensor and actuator, ensuring only correctly coded actuators can initiate a response.

Importance in Industrial Applications

In modern automation and machinery control systems, RFID switches offer enhanced safety, reduced maintenance, and increased system reliability. They are especially valuable in environments where contamination, vibration, or misalignment may affect traditional contact-based safety switches.

Key Features of RFID Switches

- RFID switches are available with multiple output types, including OSSD and relay outputs, to accommodate a range of control architectures. Devices are rated for specific switching currents, allowing safe operation within the electrical specifications of the system.

- Each switch model specifies a minimum distance between the actuator and sensor required for reliable detection, with some offering extended sensing ranges for loose tolerance applications.

- To ensure proper functionality, selecting a suitable actuator is essential—models may be coded uniquely or generically, with flat, cylindrical, or slotted geometries.

- The degree of protection offered by most RFID safety switches includes IP67 to IP69K, providing excellent protection requirements for dusty, wet, or high-pressure wash-down environments.

- RFID switches support series connection of multiple devices without degrading the overall safety level, simplifying multi-zone installation while maintaining compliance with safety standards.

- RFID switches come in multiple connection types, including cable sleeves, M12 connectors, and terminal blocks, allowing compatibility with diverse mounting and wiring schemes. This variety supports quick installation across new and legacy systems.

- They support circuit monitoring functions, ensuring continuity and real-time detection of open circuits or wiring faults. This enhances system reliability, particularly in series-connected configurations.

- Devices are rated for high impulse voltage and insulation voltage, providing robust protection against surges, interference, and electrical noise. This makes them suitable for demanding industrial environments with frequent voltage transients.

- These switches accommodate a range of circuit currents and load currents, making them adaptable for integration into light-duty signaling circuits or heavier relay-activated circuits.

- Most RFID safety switches operate using a 24V DC power supply, aligning with common industrial standards. Models with relay contacts and fixed or programmable output voltage ensure straightforward integration into safety controllers and PLC-based systems.

- Modern RFID switches offer monitoring outputs that enable real-time diagnostics and integration with higher-level control systems. These outputs support predictive maintenance and alert systems.

- Switches also feature varying switching distances, accommodating flexible installation tolerances while maintaining reliable operation across actuator types. Most devices operate on a low-voltage power supply, typically 24V DC, making them suitable for standardized industrial control environments.

- Many include integrated evaluation electronics, eliminating the need for external safety modules and simplifying wiring in safety sensor installations.

Non-Contact Safety Solutions

One of the core advantages of RFID switches is their non-contact operation. This design eliminates mechanical wear and reduces contamination, making them ideal for hygienic environments, food processing lines, and cleanrooms.

Advanced Multicode Evaluation

RFID safety switches support various coding levels—basic, coded, and uniquely coded—for flexible integration into safety architectures. Advanced multicode evaluation allows multiple actuators to be recognized, offering redundancy and programmable logic functionality.

LED Indicators for Status Monitoring

Integrated LED indicators provide real-time status updates for switch activation, power, and fault conditions. This feature simplifies diagnostics, speeds up troubleshooting, and enhances operator awareness.

Safety Standards and Compliance

RFID switches are essential components in safety-rated systems, particularly for safeguarding safety doors in manufacturing and processing environments. When used in conjunction with safety switch modules, these devices contribute to meeting stringent Safety Category levels and functional safety requirements. Their non-contact operation and secure coding support compliance in series safety switches architectures, ensuring proper alignment and reliable operation of multiple interlocks.

Each unit typically incorporates redundant safety contacts to maintain control even in the event of actuator misalignment or partial failure, ensuring a consistent and high-integrity response in safety circuits.

EN ISO 13849-1 Overview

RFID switches are engineered to comply with EN ISO 13849-1, the key international standard for machinery safety. This ensures that the devices meet rigorous requirements for system reliability and performance.

Understanding PL e/SIL 3 Safety Levels

High-end RFID safety switches can achieve Performance Level e (PL e) and Safety Integrity Level 3 (SIL 3), offering the highest levels of safety assurance in automation systems. These levels are crucial for applications involving hazardous machine operations.

Compliance with IP69K Standards

Many RFID switches feature ingress protection ratings up to IP69K, signifying resistance to high-pressure, high-temperature wash-downs—ideal for pharmaceutical and food industry use cases.

Types of RFID Switches

Plug Connectors vs. Cable End Sleeves

RFID switches are available with different connection options, including M12 plug connectors and pre-wired cable end sleeves. Plug connectors offer ease of installation and replacement, while cable ends provide permanent wiring for tamper-proof reliability.

Tamper-Proof Designs

To prevent manipulation, RFID switches come in tamper-resistant housings with high-coded actuators. This reduces the risk of intentional or accidental bypass and enhances overall machine safety.

Actuating Range Variations

Different models support a variety of actuating ranges, from a few millimeters up to 20mm or more, allowing flexibility in mechanical design and system layout.

Major Brands and Models

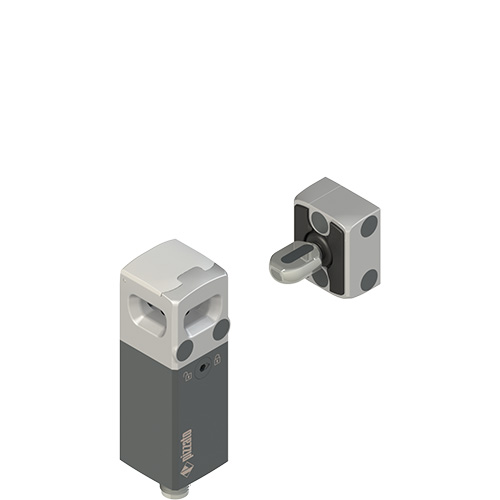

Pizzato ST Series Overview

The Pizzato ST Series delivers a robust solution for machine safety using high-coded RFID technology. These RFID switches are designed for non-contact operation, allowing safe detection of actuators with enhanced tamper resistance. With a housing made for durability, the ST Series provides IP69K-rated protection against dust and water ingress. Standard features include LED status indicators, multiple coding levels, and M12 quick-connect options, making them ideal for food processing, pharmaceutical, and general automation environments. These switches are compatible with Pizzato’s modular actuator system, supporting both flat and flexible actuator geometries.

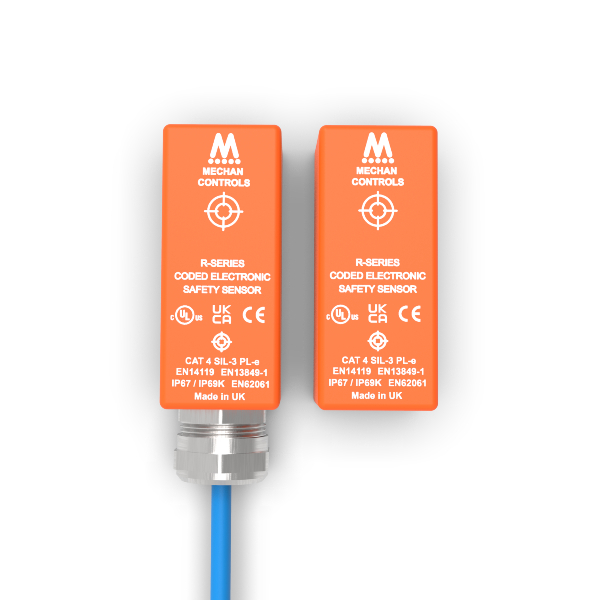

Mechan RSSG Series Overview

Mechan’s RSSG Series is built for heavy-duty machine guarding where high mechanical stress or environmental contamination is common. These switches combine RFID technology with robust, fully encapsulated housings to resist shock, vibration, and debris. RSSG models meet PL e and SIL 3 safety levels and feature dual safety outputs (OSSD), built-in LED diagnostics, and the capability to connect multiple switches in series. Their compact design allows flexible mounting, while the coded RFID link between actuator and switch offers dependable protection against bypass or manipulation.

Overview of EUCHNER RFID Switches

EUCHNER’s CES Series RFID safety switches are highly regarded for their smart, modular safety capabilities. These switches offer both standard and uniquely coded actuators, and can be integrated with locking mechanisms (CTP series) for advanced access control. The CES series includes IO-Link and ProfiSafe connectivity, allowing seamless integration with modern industrial networks. EUCHNER’s systems also support diagnostic memory, LED indicators, and extensive configuration through dedicated software—making them ideal for automotive, robotics, and multi-zone safety applications.

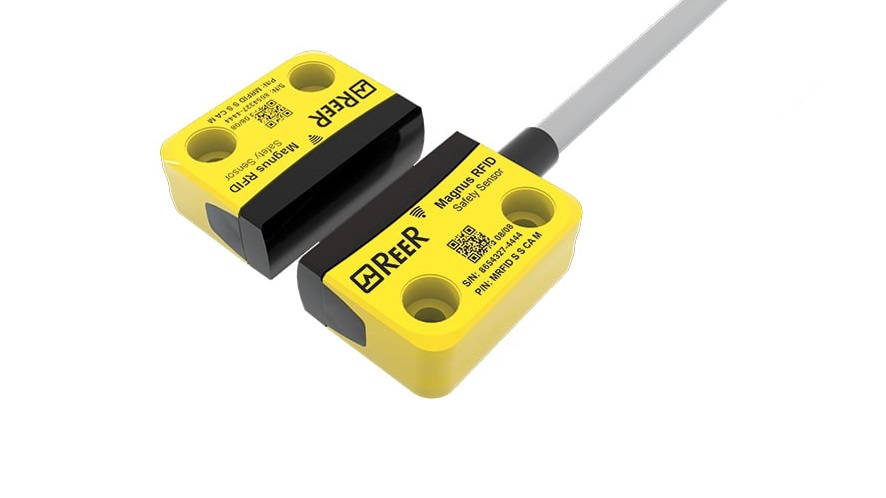

ReeR RFID Switch Characteristics

ReeR’s RFID safety switches are known for their compact footprint and adaptability to diverse automation needs. Designed to function with ReeR’s safety PLCs and control units, these switches offer multiple actuator coding options (low, high, and unique), reducing the risk of tampering. Their design supports front or side actuation, and LED indicators ensure fast setup and troubleshooting. IP67/IP69K-rated models are available for harsh environments, making them suitable for packaging, bottling, and material handling systems.

Compatibility and Integration

RFID safety switches support integration with various feedback inputs and feedback loops, providing continuous monitoring of safety conditions and actuator alignment. These features enable the development of closed-loop safety systems for high-integrity applications.

Mounting parameters, including the required mounting distance, vary by model and actuator type. Proper installation ensures consistent performance and prevents false triggering or missed detections.

Devices are designed to connect directly to safety inputs on PLCs or safety relays, ensuring compliance with functional safety architectures. Supported supply voltage is typically 24V DC, which aligns with standard industrial power configurations and simplifies panel design.

These systems are engineered to meet strict functional safety criteria, ensuring reliable performance in SIL- and PL-rated applications. The compatibility with contemporary safety protocols and diagnostics allows for smart factory and IoT integration.

Working with Various Actuators

RFID switches are designed to function with multiple types of actuators, including flat and cylindrical styles. The actuator and switch are coded to each other for safe and secure operation.

Compatibility with Contemporary Safety Systems

These switches integrate easily into modern industrial safety systems including PLCs, safety relays, and distributed I/O modules. Many offer OSSD (Output Signal Switching Device) outputs and diagnostics for smart factory integration.

Technological Advancements

Unique vs. Generic Coding

Advanced RFID switches allow users to select between uniquely coded actuators—tied to a single switch—and generically coded ones—usable across multiple switches. This flexibility supports both high-security and scalable system configurations.

Innovations in RFID Safety Solutions

Recent innovations include RFID switches with wireless transmission, edge computing for predictive diagnostics, and seamless integration with cloud-based safety monitoring platforms.

Benefits of Using RFID Switches

Enhancing Safety in Industrial Environments

By eliminating mechanical wear and improving resistance to tampering, RFID switches help maintain consistent safety integrity across a wide range of industrial environments.

Ensuring Secure Operational Procedures

RFID switches prevent unauthorized machine access and ensure only verified actuators can enable machinery. This enhances both operational security and process accountability.

Future Trends in RFID Switch Technology

The future of RFID switches lies in smarter, more connected systems. Expect more switches to include IoT compatibility, predictive maintenance features, and increased integration with cloud and AI-based safety analytics.