In modern industrial automation, stepper motors play a vital role in delivering accurate, repeatable motion control. They bridge the gap between mechanical simplicity and digital…

In modern industrial automation, stepper motors play a vital role in delivering accurate, repeatable motion control. They bridge the gap between mechanical simplicity and digital precision, offering engineers reliable control over position and speed. From CNC routers and 3D printers to robotic arms and medical devices, stepper motors are integral to countless systems requiring exact positioning.

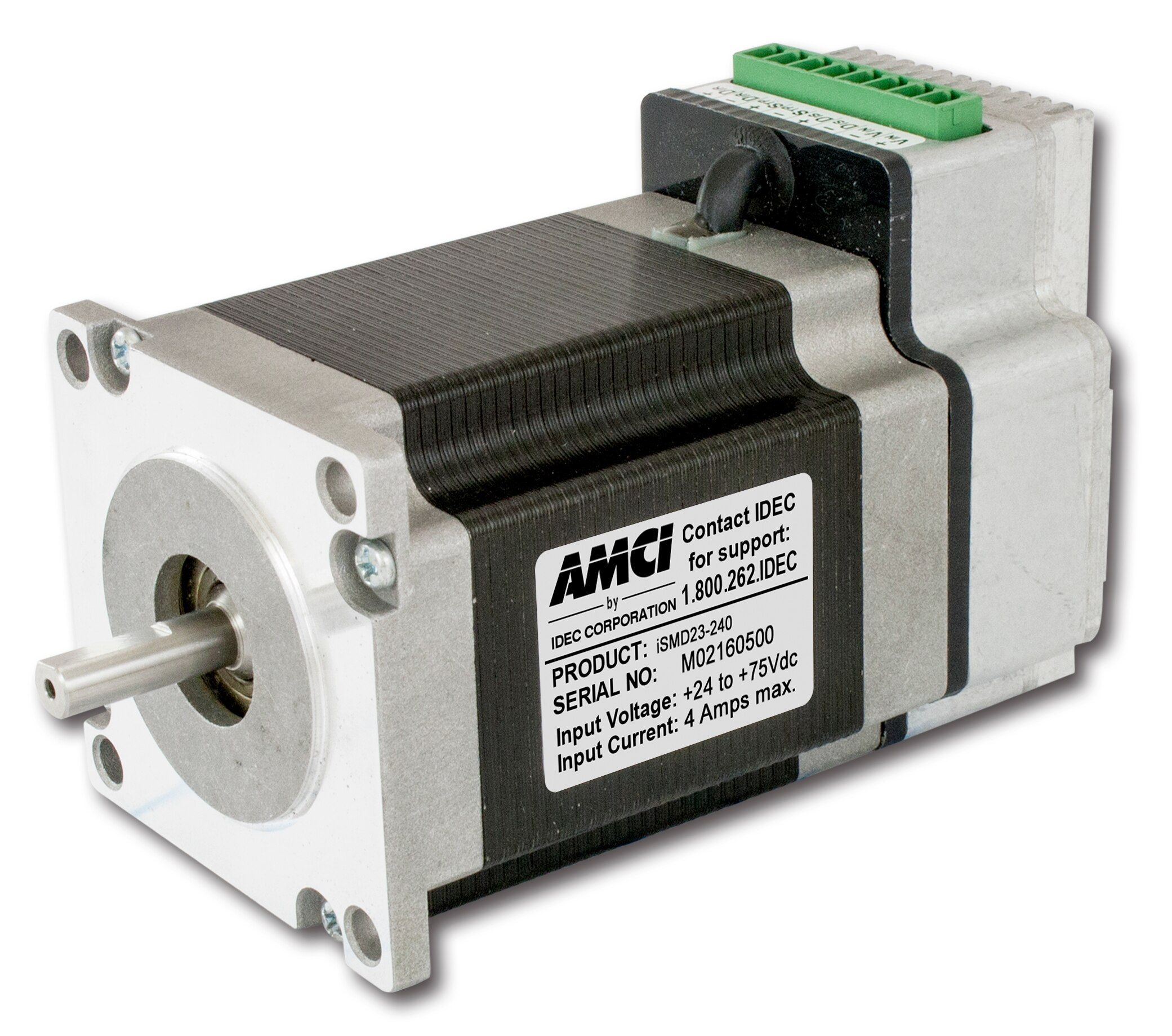

At Venus Automation, we supply a wide range of stepper motors, drivers, and controllers engineered for dependable operation across both new and legacy installations. These devices complement servo drives and other automation solutions, forming part of Venus Automation’s broader industrial control offerings.

What Is a Stepper Motor?

A stepper motor is an electromechanical device that converts electrical pulses into mechanical movement. Each pulse corresponds to a fixed angular displacement known as the step angle, enabling precise incremental control of rotation. Unlike brushless DC motors, which rotate continuously, stepper motors move in defined increments, making them ideal for open-loop control and closed-loop control systems alike.

Common Stepper Motor Types

-

Unipolar stepper motors – Simple wiring, suitable for cost-effective, low-power setups.

-

Bipolar stepper motors – Offer higher efficiency and holding torque, preferred for industrial automation.

-

Hybrid stepper systems – Combine both designs for improved torque density and smoother operation.

Standard frame sizes range from NEMA 8, NEMA 11, and NEMA 17 for compact applications to NEMA 23, NEMA 24, NEMA 34, and NEMA 42 for heavy-duty motion control. Selection depends on body length, torque requirements, and mechanical mounting.

How Stepper Motors Work

Stepper motors use sequentially energized coils to produce motion in discrete steps. A driver circuit sends pulses—called the driver pulse—to each winding in sequence, moving the rotor by one step angle at a time.

Key Components

-

Rotor and stator – The magnetic assembly that determines torque resolution and positional accuracy.

-

Drive electronics – Control phase current, current per phase, and pulse rate.

-

Power supply – Provides stable voltage and power input for constant torque output.

Advanced motion systems often employ vector control, PID loop algorithms, or DSP chip-based control for improved accuracy and reduced motor heating. Some models integrate variable current control technology and smoothing filter technology to suppress vibration and resonance issues during high-speed operation.

Closed-Loop Stepper Motors

Traditional stepper systems use open-loop devices, assuming the motor executes every commanded step. However, closed-loop stepper motors add a feedback device such as an incremental encoder, quadrature rotary encoder, or even a Mechanical Absolute Encoder to verify actual position in real time.

Advantages of Closed-Loop Systems

-

No missed steps – Automatic correction ensures position accuracy even under load.

-

Reduced heat – Variable current control lowers power consumption during idle torque phases.

-

Smooth operation – Closed loop stepper drives dynamically adjust phase current for consistent torque.

-

Overload protection – Detects abnormal torque loads or overload conditions and corrects automatically.

Advanced models like the αSTEP AR Series and αSTEP AZ Series exemplify this concept, integrating high-resolution feedback and gain tuning for superior closed loop performance. These are particularly effective in pick-and-place robots, laboratory automation, and machine vision systems requiring rapid acceleration and short-distance quick start-stop behavior.

Stepper Drivers and Controllers

A stepper motor driver or controller acts as the interface between the command system—such as a PLC, microcontroller, or dedicated motion controller—and the motor. Drivers regulate phase current, acceleration profiles, and PWM switching for accurate motion control.

Key Driver Features

-

Protection circuits for overcurrent, reverse polarity, and thermal shutdown.

-

Support for protocols like Modbus TCP/IP and BACnet MS/TP for system integration.

-

Enhanced logic from platforms such as Performance Motion Devices and JVL International, offering advanced synchronization for servo stepper hybrids.

-

Compatibility with MASSO Controller Portfolio or Ocean Controls boards for flexible system architecture.

Some advanced drivers also integrate a feedback type resolver or rotor position detection sensor, enabling full load position control and step-loss compensation during operation.

Stepper Motors vs Servo Motors

Both servo and stepper motors serve motion control applications, but their characteristics differ significantly.

Key Differences

-

Stepper motors are ideal for precise, repeatable motion at lower speeds with strong holding torque.

-

Servo motors (or brush-less servo systems) excel in high-speed, high-load applications requiring continuous feedback.

-

Hybrid stepper systems combine both technologies to provide a cost-efficient middle ground, delivering good torque and feedback without complex tuning.

Servo motors rely on continuous feedback through encoders, while stepper motors execute predetermined steps. However, closed loop stepper motors now blur this boundary, offering servo-like precision with simpler integration.

Technical Parameters

When designing or selecting a stepper system, several electrical and mechanical factors define performance.

Electrical Parameters

-

Resistance per phase and inductance per phase determine current response and dynamic torque.

-

Phase current influences heat dissipation and acceleration performance.

-

Power Supply voltage affects top speed and holding torque capability.

Mechanical Parameters

-

Body length and frame sizes dictate torque output.

-

Max. Holding Torque defines the maximum static load without motion.

-

Torque resolution impacts positional accuracy and smoothness.

These factors, when properly balanced, deliver reliable motion control across industrial control solutions and precision automation systems.

Applications of Stepper Motors

Stepper motors are used across industries for both linear and rotary motion control.

Common Applications

-

CNC Machines – Precision movement of spindles and tool heads.

-

3D Printers – Layer-by-layer deposition with high accuracy.

-

Robotics – Reliable joint control with defined motion profiles.

-

Packaging Machines – Timing-critical feed and label placement.

-

Optical Equipment – Lens alignment and fine positioning using incremental encoders.

-

Automation Test Rigs – Positioning operations in laboratory and production environments.

Stepper motors also appear in industrial automation systems using PLC control, performance motion devices, and DSP-based motion boards.

Integration and Setup Tips

To maximize performance and lifespan, consider these setup principles:

-

Match the driver to the motor — Ensure voltage, current, and phase current ratings align.

-

Optimize wiring — Use shielded cables and a proper wiring harness to reduce EMI.

-

Cooling — Provide airflow or heat sinks to prevent motor heating in continuous operation.

-

Fine-tune motion — Adjust gain tuning or PID loop settings for smoother acceleration.

-

Use quality accessories — Select compatible connectors and Power Supply units for stable performance.

-

Check technical documentation — Refer to TI specifications, TI E2E™ forums, or community contributors for parameter support.

Advanced automation setups may include step-loss compensation, load position control, and feedback type resolver integration for peak efficiency.

Choosing the Right Stepper Motor

When choosing a stepper motor, engineers should evaluate:

-

Application load and inertia

-

Torque and speed requirements

-

Control method (open-loop vs closed-loop)

-

Available driver interface and feedback type

-

Space constraints and body length

For high-precision, servo stepper hybrid applications, combining a closed-loop stepper with an Electromagnetic Brake can enhance safety and positioning stability.

Stepper motors remain a cornerstone of precise motion control, providing unmatched reliability in automation environments. With the emergence of closed-loop stepper motor technology, engineers can now achieve servo-level accuracy with simplified integration. Combined with intelligent drivers, optimized Power Supply units, and expert technical support, stepper motors continue to advance industrial productivity and efficiency.

At Venus Automation, we deliver stepper motors, drivers, and accessories built with high-quality materials and backed by engineering expertise. Whether you need compact NEMA motors, hybrid closed-loop stepper drives, or full-scale automation integration, our team can help you achieve dependable and efficient motion control.