In the world of modern automation systems, precision movement and repeatable motion cycles are vital. Indexers — whether rotary indexers, cam indexers, or servo mechanical…

In the world of modern automation systems, precision movement and repeatable motion cycles are vital. Indexers — whether rotary indexers, cam indexers, or servo mechanical indexers — play a central role in achieving these functions. They enable components to move, stop, and position accurately during production processes such as assembly automation, packaging machines, robotic welding positioners, and linear transfer systems.

At Venus Automation, we supply a complete range of index drives, servo rotary tables, and cam indexing systems that deliver exceptional indexing accuracy and reliability for industrial environments across Australia.

What Are Indexers?

An indexer is a motion control device that divides a complete rotation or linear movement into equal increments known as indexing patterns. These devices control the motion of a rotating plate or table with precise angular or linear displacements.

Typical configurations include:

- Rotary Indexers – For circular motion in automated rotary tables and manufacturing machinery.

- Cam Indexers – Using a mechanical cam to ensure repeatable and synchronized motion cycles.

- Servo Indexers – Integrated with servo motors and motion controllers for programmable operation.

Each type provides high torque, minimal backlash, and long service life through optimized gear reducers, output shafts, and contact bearings.

How Cam Indexers Work

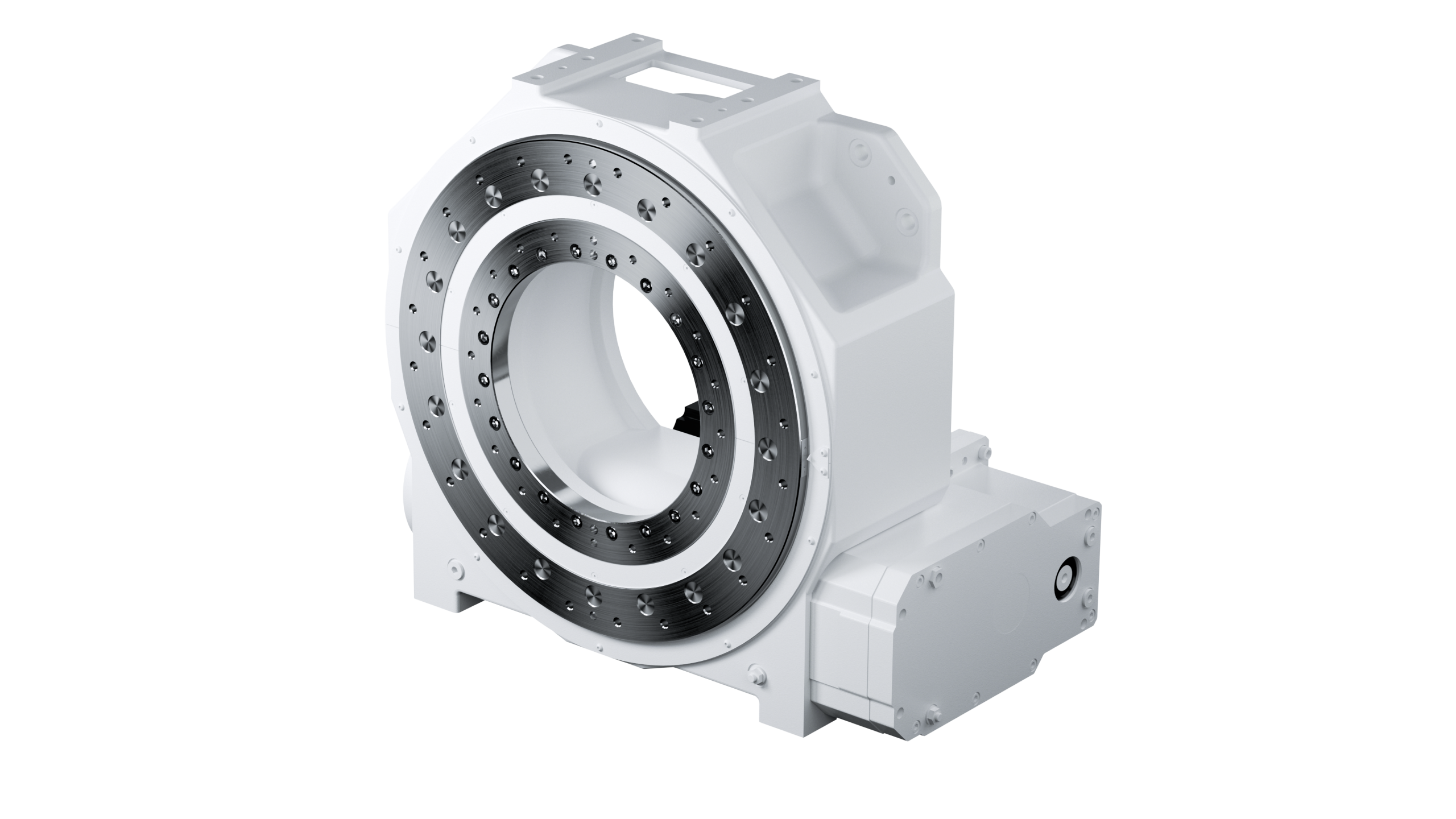

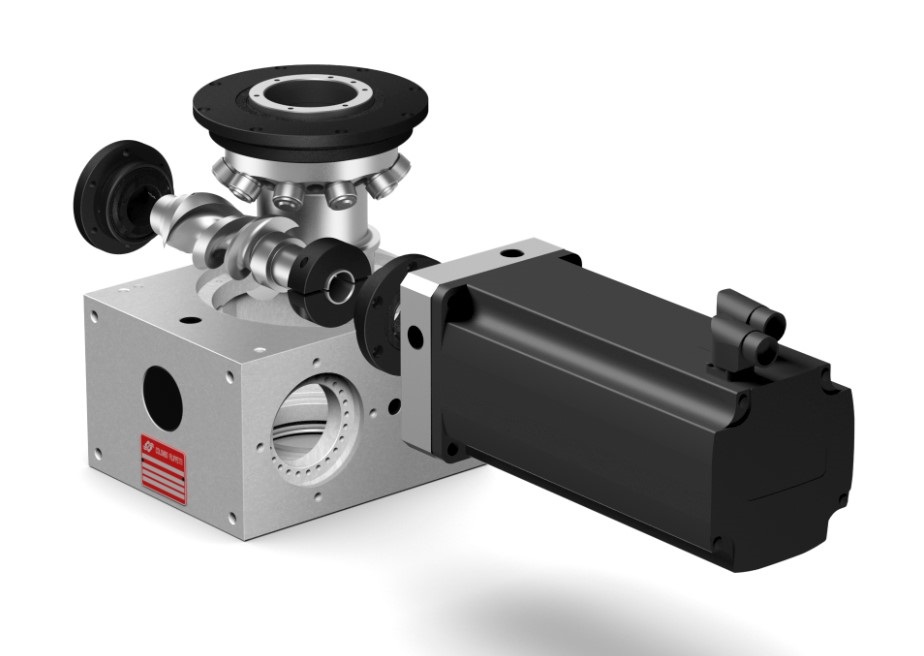

Cam indexers convert continuous rotary motion into intermittent motion through a cam indexing drive. A cam profile determines the indexing angle, indexing time, and dwell period. This design ensures smooth and vibration-free motion.

The rotary cam indexer and globoidal cam indexer are common types, offering compact construction and excellent mechanical repeatability. In high-speed assembly technology or welding technology, these systems provide fixed move modes and goto modes that coordinate mechanical movements between tooling stations.

Advanced models such as SAG Cam Indexing Systems or DE Flange & Shaft Output Cam Indexing Systems feature hardened camshafts and optimized drive mechanisms for reliable operation under heavy loads.

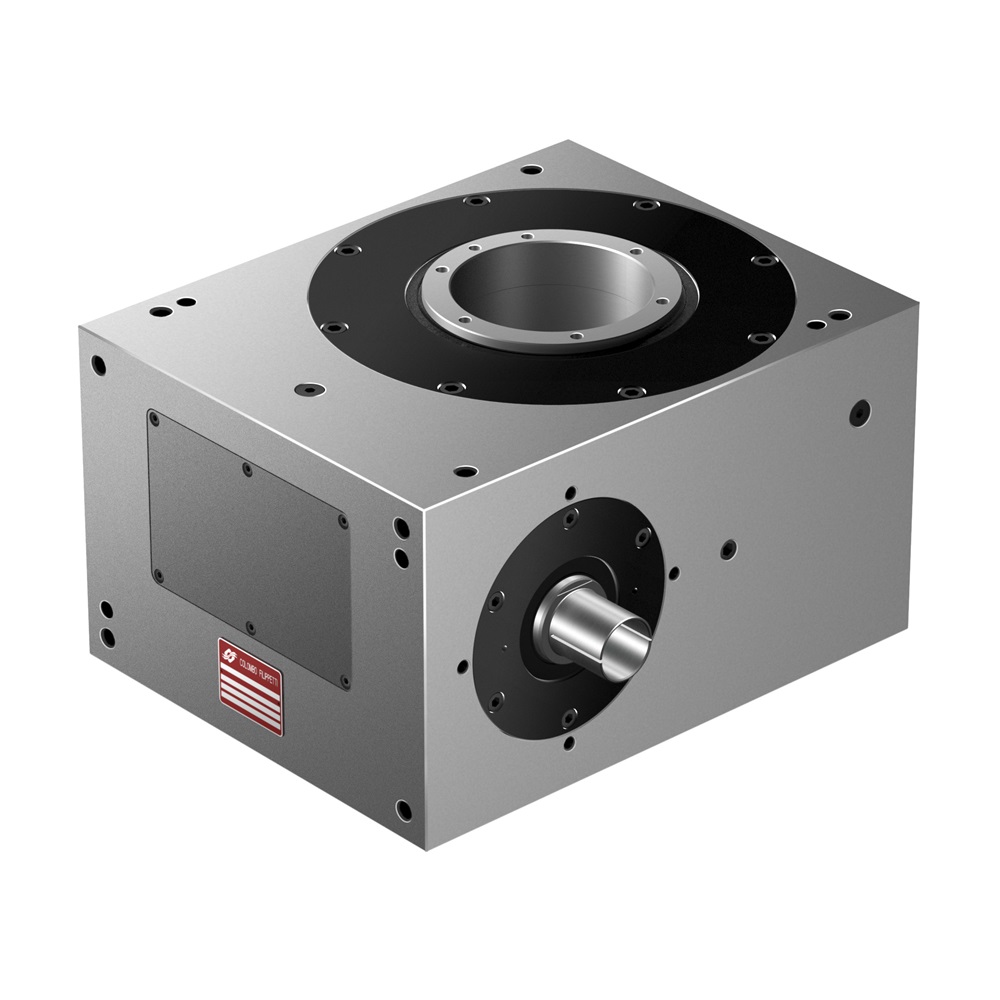

Servo and Motion Index Drives

Modern servo rotary tables and motion index drives combine the mechanical precision of traditional cam systems with the flexibility of electronic control.

Paired with servo motors, these units provide programmable speed, dwell, and direction via digital control systems or UNICO’s P-Terminal interfaces.

Key advantages include:

- Programmable Outputs for adaptive control.

- Variable Stepless Speed Changers for different production rates.

- Absolute Encoders ensuring closed-loop motion control accuracy.

- Permissible Output Axial and Radial Loads defined for robust mechanical reliability.

This hybrid design is widely used in assembly automation, pharmaceutical manufacturing, and testing technology applications that demand high flexibility and uptime.

Applications in Automation and Manufacturing

Indexers and rotary index tables are indispensable across a wide range of industrial processes:

- Automated Assembly Lines – Precise motion for robotic and manual assembly.

- Packaging Machines – Coordinating feed, seal, and cut cycles.

- Weld Positioning Systems – Positioning workpieces in robotic welding positioners.

- Tool Tray Transfer Systems – Enabling quick repositioning for testing technology or inspection systems.

- Link Conveyors and Linear Transfer Systems – Handling heavy materials across stations.

In these setups, cam indexing gearboxes and servo rotary tables ensure synchronization with surrounding components, guaranteeing precise and consistent movement every cycle.

Design and Integration

When integrating index drives into an automation sector application, several factors determine optimal performance:

- Indexing Angle and Time – Define acceleration and deceleration phases.

- Output Shaft and Gear Reducer Design – Handle mechanical stress and torque transmission.

- Large Central Openings – Allow for wiring, piping, or feeding mechanisms through the center.

- Indexing Plate and Flange Mounting – Enable easy integration into rotary tables or conveyors.

Manufacturers like WEISS GmbH, Hansheng Automation, and Sango Automation offer advanced cam indexers and servo rotary tables suitable for integration into Venus Automation’s modular control platforms.

Precision, Support, and Delivery

At Venus Automation, we combine global expertise with local service. Our engineers help specify the correct motion index drive, servo rotary table, or cam indexer gearbox to match your torque, speed, and indexing accuracy requirements.

We provide detailed product information, delivery times, and responsive customer service across Australia, ensuring your system stays efficient and compliant. Our shipping service includes tracked return shipping options for warranty exchanges and maintenance support.

Conclusion

From rotary cam indexers and servo rotary tables to globoidal cam indexers and motion index drives, Venus Automation delivers high-precision motion equipment for every automation system. Whether used in assembly technology, pharmaceutical manufacturing, or packaging machines, our products guarantee reliability, speed, and precision.

Trust Venus Automation — Australia’s industrial motion specialists — for expert guidance, dependable delivery, and cutting-edge indexing solutions designed to power the next generation of automation systems.