Variable Speed Drives (VSDs) are the backbone of efficient motor control in modern industrial automation.But to achieve their full potential — in reliability, protection, and…

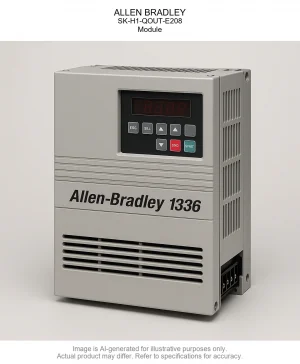

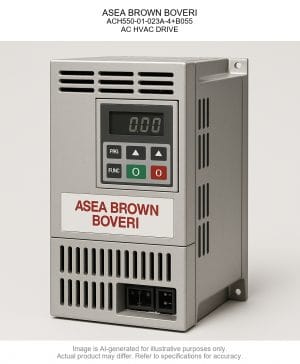

Variable Speed Drives (VSDs) are the backbone of efficient motor control in modern industrial automation.

But to achieve their full potential — in reliability, protection, and precision — they depend on the right accessories. From braking resistors and line reactors to communication modules and EMC filters, Variable Speed Drive accessories extend system life, improve performance, and ensure compliance with electrical standards.

At Venus Automation, we supply a comprehensive range of VSD accessories and automation components that complement our lineup of Variable Speed Drives, helping engineers achieve optimal results in every installation.

Why VSD Accessories Matter

Variable Frequency Drives (VFDs) manage the speed, torque, and direction of motors by adjusting AC power frequency. However, electrical noise, voltage fluctuations, and system harmonics can compromise performance.

That’s where VSD accessories come in — providing power conditioning, signal protection, and reliable system integration.

These components not only enhance motor protection and energy efficiency, but also reduce maintenance costs and ensure compliance with IEC standards in demanding environments.

Essential Variable Speed Drive Accessories

1) Braking Resistors

Braking resistors dissipate excess energy generated when motors decelerate rapidly. Without them, VFDs can trigger overvoltage faults.

Used in conveyors, cranes, and elevators, they protect both the drive and AC motors from energy spikes.

Pair your braking systems with Safety Relays or Emergency Stop Relays for improved operator safety.

2) Line Reactors and Chokes

Line reactors (input chokes) and output reactors (load chokes) reduce harmonics and protect drives from voltage transients.

They stabilize the current entering the drive, lowering harmonic distortion and extending motor lifespan.

For heavy-duty systems, pair reactors with robust Power Supplies to keep the DC rails steady.

3) EMC Filters and RFI Suppression

To meet electromagnetic compatibility (EMC) requirements, most drives use EMC filters or RFI suppression modules.

These accessories minimize interference with nearby control systems, sensors, and Safety PLCs.

They’re especially critical in HVAC, medical, and food processing installations where electrical noise affects system reliability.

4) Control and Communication Modules

Communication cards expand how drives connect with PLCs and HMIs, enabling smart integration and real-time feedback.

Popular interfaces include Modbus, EtherNet/IP, Profibus, and CANopen.

Our Operator Interfaces for Automation and HMI Touch Panels provide intuitive control for multi-drive systems.

5) Shielded and Armored Cables

Shielded control cables prevent electrical interference between power and signal lines, ensuring accurate speed control and torque regulation.

For reliable wiring, use cable glands, ferrite cores, and earth grounding kits with your drives.

You can find compatible boxes and Electrical Enclosures in our catalogue.

6) Cooling Fans and Heatsinks

Effective thermal management is essential for maintaining drive performance. Cooling fans, heatsinks, and thermal sensors prevent overheating during continuous operation.

For high-duty applications, add Power Relays and temperature monitoring to operate safely within specified limits.

7) Enclosures and Mounting Kits

Drives in dusty or humid environments need IP-rated enclosures (IP55/IP66).

We stock versatile Enclosures and Palazzoli junction solutions such as the TAIS enclosure family. See: TAIS Interlocked Sockets & Boxes.

Accessories like mounting brackets, DIN rails, and ventilated panels simplify installs and maintain airflow.

8) Input/Output Reactors

Input reactors protect drives from line transients and electrical noise, while output reactors limit long-cable voltage spikes.

Together, they extend motor insulation life and ensure smoother operation, especially when combined with Soft-starter / panel hardware in multi-motor systems.

9) Braking Units and Dynamic Load Modules

When a motor stops abruptly, regenerative energy flows back to the drive. Dynamic braking units safely manage this return energy through external resistors — common in conveyors, hoists, and centrifugal fans.

10) Harmonic Filters and Surge Protection

Passive/active harmonic filters maintain power quality and reduce distortion on the supply network.

In parallel, surge protection devices guard against voltage spikes from switching or lightning — key for AS/NZS 61000 compliance.

Control and Interface Add-Ons

VSD accessories also improve usability and operator experience:

-

Remote keypads and speed potentiometers for manual control without opening enclosures.

-

Digital operator panels to view voltage, output frequency, and load %.

-

RS-485 adapters and USB programming cables for PC configuration.

Integrate these with Safety PLCs and our Servo content & products for streamlined monitoring and remote troubleshooting.

Accessories for System Safety and Longevity

System reliability doesn’t stop at the drive. The right accessories protect surrounding equipment and enhance machine safety:

-

Safety Mechanical Interlocks – Ensure isolation during maintenance.

-

Safety Light Curtains – Detect operator movement near hazards.

-

Safety Enabling Switches – Allow controlled access for setup/testing.

-

Emergency Stop Relays – Provide immediate shutdown when necessary.

Together, these elements work seamlessly with your VFD system, reducing downtime and electrical damage.

Choosing the Right VSD Accessories

When selecting accessories, consider:

-

Drive power rating and current capacity

-

Motor type and load profile

-

Cable lengths and voltage drop limits

-

Environment (temperature, dust, humidity)

-

Communication protocol (Modbus, Ethernet, CANopen)

-

Compliance with IEC and AS/NZS standards

For example, braking resistors and filters are essential for high-torque applications, while communication cards and operator panels boost visibility in smart-factory systems.

Integration with Other Automation Components

Venus Automation accessories integrate with:

-

Servo Motors for precision torque/speed

-

HMI Touch Panels for live monitoring

-

Safety PLCs for safe machine logic

-

Safety Relays for emergency response

Each accessory enhances operational efficiency — making drives safer, smarter, and easier to maintain.

Why Choose Venus Automation

Venus Automation is Australia’s trusted supplier of Variable Speed Drives, Drive Accessories, and Industrial Control Components. We provide:

-

Expert technical support for system design and setup

-

Fast, nationwide delivery on stocked items

-

Training programs for installers and integrators

-

Transparent warranty policies and after-sales assistance

Our goal is to help clients build reliable, efficient automation systems that meet Australian and international standards.

Variable Speed Drive accessories are essential for maintaining system stability, protecting components, and enhancing automation control.

From line reactors and EMC filters to communication modules and braking resistors, each accessory contributes to performance, safety, and long-term reliability.

Whether upgrading existing panels or designing new systems, Venus Automation delivers the right accessories and expertise to keep your VFD systems efficient, protected, and ready for continuous operation.