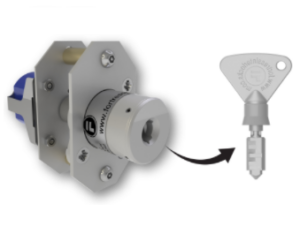

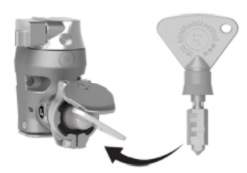

Interlocks and keys are essential safety devices used to control access to hazardous areas and prevent unauthorized operation of machinery. By enforcing specific safety sequences,…

Interlocks and keys are essential safety devices used to control access to hazardous areas and prevent unauthorized operation of machinery. By enforcing specific safety sequences, they ensure that machinery remains powered off or inaccessible until all safety protocols are followed. These systems help prevent accidents, protect personnel, and ensure compliance with safety regulations in industrial environments.

Key Features:

- Mechanical or Electromechanical Operation

Available in both mechanical and electronic versions to suit different safety requirements. - Sequential Safety Control

Ensures access is granted only after completing predefined safety steps, such as power isolation. - Key Retention Mechanism

Holds the key until it is safe to proceed, preventing accidental or premature access. - Robust Construction

Designed to withstand harsh industrial environments, including dust, moisture, and vibration.

Applications:

- Machine Guarding

Prevents machine operation while access doors or guards are open. - Hazardous Area Access Control

Ensures entry to high-risk zones only when it is safe to do so. - Power Isolation Procedures

Ensures that machines are powered down during maintenance or servicing. - Production Line Safety

Controls the flow of work and prevents access to moving parts during operation.

Interlocks and keys enhance operational safety and efficiency by enforcing controlled access and step-by-step procedures, making them indispensable in industries where safety is critical.