Infrastructure LED Light Fixtures & Floodlights – Stainless Steel Corrosion-Proof, High-Reliability Lighting for Critical Assets In infrastructure environments where corrosion, wash-down, heat, vibration, and continuous…

Infrastructure LED Light Fixtures & Floodlights – Stainless Steel

Corrosion-Proof, High-Reliability Lighting for Critical Assets

In infrastructure environments where corrosion, wash-down, heat, vibration, and continuous duty are the norm, stainless steel LED light fixtures and floodlights are specified because they reduce risk. Built for compliance and predictable performance, these luminaires deliver consistent illumination across assets where failure isn’t acceptable.

Where Stainless Steel Lighting Solves Real Problems

Specified across critical infrastructure where coated housings fail early:

- Road and rail tunnels

- Ports, harbours, and marine terminals

- Electrical substations and utilities

- Wastewater and treatment plants

- Industrial plants and hazardous environments

- High-temperature and aggressive wash-down zones

The goal is simple: lights that keep working.

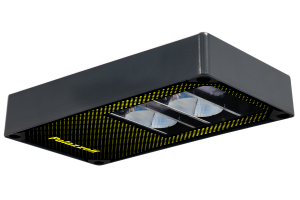

Product Types for Infrastructure Projects

Common stainless steel luminaires include:

- Stainless steel LED floodlights

- Wall, trunnion, column, and gimbal-mounted fixtures

- High-bay and low-bay luminaires

- Explosion-proof / EX-series lighting for hazardous zones

Supplied as standardised items (UOM: EA) to support consistent procurement and spares.

Why AISI 316L Stainless Steel

AISI 316L is the benchmark for infrastructure lighting:

- Superior resistance to salt, chemicals, and aggressive atmospheres

- Suitable for marine, tunnel, utility, and hazardous zones

- Maintains structural integrity at elevated ambient temperatures

Optics are paired with tempered glass, safety glass, or polycarbonate lenses depending on impact and glare requirements.

IP Rating, Impact & Environmental Protection

Infrastructure luminaires are specified by protection, not looks:

- IP65 to IP69K ingress protection

- IK02 to IK10+ impact ratings

- Controlled-compression silicone gaskets

- Certified cable glands, dual hub entries, secure terminal blocks

- Condensation resistance for tunnels and enclosed spaces

This ensures reliability in outdoor, corrosive, and enclosed environments.

Optical Performance You Can Engineer Against

Stainless steel LED floodlights deliver measurable, documented output:

- Luminous flux / output flux (not just wattage)

- Symmetrical and asymmetrical beam options

- CAD-optimised optics and lab-verified photometric curves

This supports compliant lighting for tunnels, yards, perimeters, and plant areas.

Electrical Characteristics for Infrastructure Networks

Designed for utility-grade supply:

- 240 V AC, 50 Hz

- High power factor

- Integrated surge protection

- Stable integral drivers

Options may include 0–10 V dimming, remote control, and battery backup for emergency lighting integration.

LED Lifetime & Serviceability

Engineers prioritise predictable life:

- Documented LED technology

- L70 lifetime targets

- Stable output over time

- Field-replaceable LED boards on select systems

This minimises maintenance in hard-to-access locations.

Hazardous Areas & Explosion Protection

Where required, stainless steel luminaires are available as:

- Explosion-proof LED lighting

- Certified to Ex d, Ex e, Ex i, or Ex p protection concepts

Critical for chemical plants, fuel handling, and high-risk zones.

Mounting, Accessories & Installation

Built for large-scale deployment:

- Wall, column, trunnion, and gimbal mounts

- Safety cable retention points

- Quick-disconnects and multipolar cabling

- Clear installation instructions and full data sheets

Faster installs, fewer mistakes.

Engineer-Focused Selection Guide

Specify stainless steel infrastructure lighting by confirming:

- Material: AISI 316L stainless steel

- IP / IK ratings for the environment

- Photometric data and beam distribution

- Electrical specs (voltage, surge, PF)

- Thermal limits and ambient rating

- Hazardous area certification if applicable

- Mounting method and accessories

- Documentation (data sheets, compliance)

If IP rating, photometrics, or electrical data aren’t documented, don’t install it.

Built to Reduce Risk

Stainless steel LED floodlights aren’t a premium upgrade—they’re a risk-reduction strategy. With defined protection ratings, controlled optics, surge protection, and certified materials, they meet the real demands of infrastructure.

If a fixture can’t prove performance on paper, it doesn’t belong on critical assets.