Industrial Traditional & Well Glass Light Fixtures Proven Lighting for Harsh, High-Duty Industrial Environments Industrial sites need lighting that survives impact, contamination, temperature swings, and…

Industrial Traditional & Well Glass Light Fixtures

Proven Lighting for Harsh, High-Duty Industrial Environments

Industrial sites need lighting that survives impact, contamination, temperature swings, and continuous operation. Traditional industrial light fixtures and well glass luminaires are engineered for exactly that—delivering dependable illumination where decorative fittings fail.

These fixtures prioritise mechanical strength, sealing, and service life, making them a go-to solution for production halls, technical zones, and outdoor service areas.

Where Traditional & Well Glass Fixtures Solve Real Problems

Specified wherever lighting must be rugged, predictable, and low-maintenance, including:

- Manufacturing and assembly plants

- Plant rooms and technical areas

- Logistics centres and access corridors

- Exterior service routes and perimeters

- Industrial sites with vibration or airborne contaminants

Their role is simple: keep areas safely lit, shift after shift.

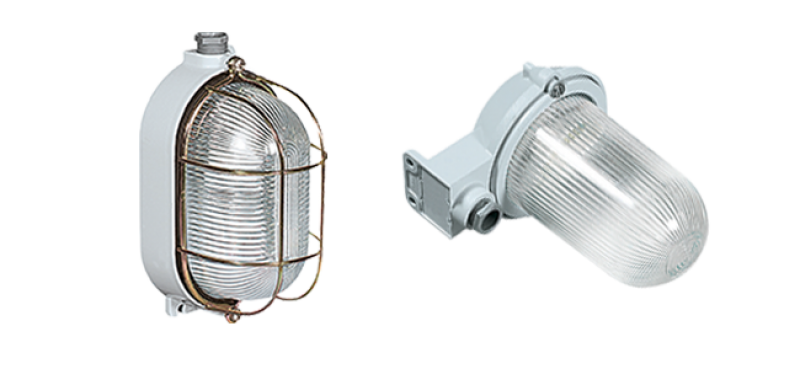

Metal & Glass Construction That Lasts

Traditional and well glass fixtures rely on metal housings and sealed glass diffusers to protect internal components.

This construction delivers:

- High impact resistance in busy work zones

- Stable light output in vibration-prone areas

- Long service life with minimal intervention

Well glass designs, in particular, shield the lamp while maintaining uniform illumination—ideal for corridors, stairwells, and plant access points.

IP Ratings & Environmental Resistance

Ingress protection is non-negotiable in industrial lighting.

These fixtures are commonly specified with industrial IP ratings to resist:

- Dust and airborne particulates

- Water spray and wash-down procedures

- Outdoor weather exposure

Proper sealing reduces failure rates and keeps maintenance predictable.

Wall-Mounted Industrial Lighting Options

Where ceiling mounting isn’t practical, industrial wall lights provide targeted illumination without consuming overhead space.

Common uses include:

- Walkways and escape routes

- Machinery perimeters

- Exterior service areas and plant access zones

Compact, robust designs support fast installation and compliance.

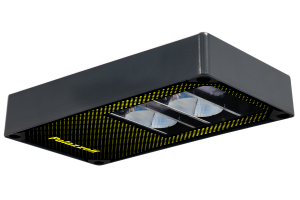

Performance First—Not Decorative Lighting

Although some terminology overlaps with architectural products, industrial traditional and well glass fixtures are not decorative.

They are specified for:

- Continuous-duty operation

- Thermal stability

- Ingress protection

- Compliance with industrial standards

This distinction matters. In manufacturing environments, reliability and compliance beat appearance every time.

Supply, Availability & Project Continuity

Industrial lighting projects depend on consistent supply and long-term support. Traditional and well glass fixtures are typically sourced through specialist electrical wholesalers and industrial suppliers who understand compliance, spares availability, and lifecycle requirements.

That reliability keeps plants running.

Engineer-Focused Selection Guide

When specifying industrial traditional or well glass light fixtures, confirm:

- Mounting type (wall, ceiling, bulkhead)

- Housing material (metal grade, corrosion resistance)

- Glass type (impact resistance, sealing method)

- IP rating for the environment

- Operating temperature range

- Lamp or LED compatibility

- Standards compliance for the site

If a fixture can’t handle vibration, wash-down, or long run times, it’s not industrial-grade.

Lighting Built for Industrial Reality

Traditional and well glass industrial light fixtures remain relevant because they work where others don’t.

Specified correctly, they deliver durable construction, predictable performance, and safe illumination across demanding industrial and commercial environments.

In industry, boring and reliable beats stylish and fragile—every time.