Types of Push Button Contact Blocks Single Contact Blocks Single contact blocks are a fundamental type of electrical circuit connector used in control devices, offering…

Types of Push Button Contact Blocks

Single Contact Blocks

Single contact blocks are a fundamental type of electrical circuit connector used in control devices, offering one normally open (NO) or normally closed (NC) contact. Ideal for simple circuits, these push button contact blocks are common in industrial machines where minimal signal logic is required. Their modularity allows easy integration with button heads, illuminated pushbuttons, and selector switches.

These blocks often come with screw clamp terminals or plug-in designs for quick wiring in complex circuits, ensuring safe, direct interaction with the control signal.

Double Contact Blocks

Double contact blocks provide two switching elements within a single housing—often one NO and one NC—for increased functionality. These blocks support momentary pushbuttons and toggle switches that need dual signal paths, enhancing versatility in safety and logic systems.

Used in control panels for machinery control, double contact blocks can handle different types of contact operations while maintaining compact installation dimensions.

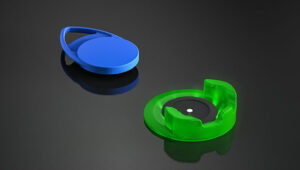

Rotary Contact Blocks

Rotary contact blocks are designed for selector switches and rotary actuators. Their mechanism rotates instead of pushing, which is ideal for toggling between multi-position states in control applications. These blocks often support a range of contact configurations, from 2-position to 5-position systems.

Common in labelling equipment and process control panels, rotary blocks are also used where tactile feedback and positional accuracy are essential for safe operation.

Multiple Contact Blocks

For more advanced or complex equipment, multiple contact blocks combine multiple sets of contacts in a single stackable module. Often used with addon blocks, these configurations offer a range of contact configurations including NO-NC-NC or NO-NO combinations.

These are ideal for applications requiring signal redundancy, feedback loops, or fail-safe functions across electrical circuits in heavy machinery and automation systems.

Specialized Emergency Stop Contact Blocks

Emergency stop contact blocks are safety-rated modules designed for E-Stop push buttons. They are built to ensure fail-safe disconnection during emergencies. Many include silver-alloy contacts or brass contacts for conductivity and reliability, and often have extra sets of contacts to trigger safety PLCs or alarms.

These blocks feature high resistance to electrical hazards, physical shocks, and dust ingress protection, making them suitable for hazardous environments and outdoor installations.

Broader integration with Safety & Automation Systems

While a fundamental building block of modern industrial control devices, and being a key part of systems such as the emergency stop button, and emergency stop rope pull, integrated safety/automation systems consist of far more than just contact blocks. For example, other critical components typically include safety PLCs, safety contactors and safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Additional peripheral safety devices like the two hand station may also be utilised.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Materials and Durability

Common Materials Used

High-performance push button contact blocks are typically manufactured using high-quality materials like:

- Silver-plated contacts for superior conductivity

- Brass contacts for corrosion resistance

- Thermoplastic or polycarbonate housings for strength and insulation

Some brands, such as Schneider Electric’s XENC series, and ABB’s MCBL Series Contact Blocks, focus on rugged builds that maintain integrity even under high-voltage environments.

Wear Resistance Properties

The durability of contact blocks is critical in applications with high actuation frequency. Advanced blocks feature:

- Reinforced contact surfaces to reduce contact wear

- Modular design to support interchangeable contact blocks

- Sealing mechanisms to block dust and debris in hazardous environments

Regular inspections of contacts and cleaning of contact surfaces are recommended for maintaining reliable performance. Many models now include plug-and-play contact blocks for easy replacement, reducing downtime and preventing equipment damage in case of failure.

Commercial Applications

Industrial Manufacturing

In industrial manufacturing, pushbutton contact blocks are essential components of operator stations and machinery control panels. They help ensure accurate electrical circuit connection in processes involving complex equipment. From packaging lines to CNC machines, these contact blocks provide reliable signal switching for start/stop operations, fault alerts, and maintenance overrides.

The use of high-quality materials like silver-plated contacts ensures longevity, even under high actuation cycles in demanding environments.

Automotive Sector

The automotive sector uses push button contact blocks in both vehicle production and testing applications. Whether integrated into equipment control stations on robotic assembly lines or within diagnostics systems, contact blocks help streamline high-speed operations without compromising safety.

Many automotive applications require single contact blocks and double contact blocks that withstand oil exposure, vibration, and electrical hazards, often certified for use in hazardous environments.

Electrical Engineering

In electrical engineering, pushbutton contact blocks support the development of complex circuits for switching, signaling, and control. Engineers often use modular pushbuttons with stackable contact blocks to simulate or prototype custom control logic.

They are also used in the design of circuit breakers, electrical connectors, and equipment panels, where quick replacement, correct contact block selection, and reliability are critical.

Commercial Construction

For commercial construction projects, contact blocks are installed in access control systems, lighting control, elevator panels, and emergency stop stations. Builders rely on durable contact blocks that offer protection against dust ingress, environmental stress, and wear from frequent use.

The ability to select from a variety of colours, actuator types, and mounting options allows for both functionality and adherence to building code color standards.

Oil and Gas Industry

Oil and gas facilities require heavy-duty contact blocks with dust ingress protection, corrosion-resistant brass contacts, and explosion-proof housing. These contact blocks often feature double-break mechanisms and closed contact logic to minimize ignition risk.

The ability to withstand high-voltage environments and integrate into fail-safe systems makes them ideal for offshore rigs, refineries, and gas processing units.

Telecommunications

In the telecommunications sector, plug-and-play contact blocks are used in infrastructure panels, network switching stations, and emergency shutdown modules. Their compact design and addon block compatibility make them well-suited for dense wiring environments.

Operators favor models like the Omron Contact Block and ABB Modular Series due to their reliability and low signal interference, ensuring uninterrupted performance in signal-critical installations.

Selecting the Right Contact Block

Assessing Application Needs

Choosing the correct contact block starts with understanding its operational role. Is it for equipment control, safety shutdowns, or signal indication? Whether you’re working with a momentary pushbutton, illuminated pushbutton, or rotary selector, matching the block type to the application ensures optimal function and longevity.

Consider factors like number of contacts, switching logic (NO/NC), and mounting type (e.g. panel mount) during selection.

Ensuring Compatibility

Ensuring compatibility with your existing button head, terminals, and enclosure is essential. Many brands offer universal blocks, while others—such as MCB-01 Contact Block, KX Contact Block, or Schneider Electric XENC Series—are product-specific.

Verify that the housing of contact blocks, mounting method, and electrical contacts align with the rest of your system to avoid misfitting or unsafe configurations.

Evaluating Safety Features

For high-risk environments or emergency stop applications, choose contact blocks with built-in fail-safe mechanisms. These include closed contact logic, silver-alloy contacts, or double contact blocks with redundancy. Look for certifications indicating resistance to electrical hazards, dust ingress, and contact wear.

Regular inspections of contacts and proper cleaning of contact surfaces will also enhance system safety.

Considering Market Trends

Modern buyers are shifting toward plug-and-play contact blocks, stackable addon blocks, and eco-friendly materials. There’s also growing demand for interchangeable contact blocks and white light indicators for enhanced visibility and quick status checks.

Following these market trends helps future-proof your installations and ensures that your system remains compatible with evolving electrical engineering practices and equipment control requirements.

Maintenance and Use

Common Maintenance Tips

To ensure optimal performance and electrical safety, pushbutton contact blocks require regular inspections. Maintenance should include:

- Cleaning of contact surfaces to prevent carbon buildup

- Checking for contact wear or oxidation on silver-alloy contacts

- Verifying tightness of screw clamp terminals or modular plug connections

- Ensuring dust ingress protection remains intact in hazardous environments

For environments with high cycling frequency, use of reliable contact blocks with reinforced contacts is recommended. Always refer to manufacturer documentation for proper replacement intervals.

Prevalent Commercial Uses

Pushbutton contact blocks are widely used in:

- Control panels for industrial automation

- Emergency stop contact blocks within safety circuits

- Machine interfaces in equipment control applications

- Custom switches for telecommunications systems and electrical engineering labs

- Signal logic in commercial construction elevator panels and HVAC controls

Their adaptability and variety of colours make them ideal for clear operator feedback and system status visibility.

Advantages of Pushbuttons and Contact Blocks

Pushbuttons and their associated contact blocks offer multiple benefits in industrial and commercial systems:

- Wide range of configurations: NO, NC, double-break, and stackable combinations

- High-quality materials such as brass contacts, polycarbonate housings, and plated terminals

- Compatibility with illuminated pushbuttons, allowing for clear visual feedback

- Easy replacement and expansion with interchangeable contact blocks and addon blocks

- Safe operation in high-voltage environments or hazardous locations due to robust insulation and certifications

Their modular pushbutton design supports custom builds and seamless integration into both old and new systems.

Notable Product Models

SVACFTLF SHORTRON Illuminated Pushbutton with LED

The SVACFTLF SHORTRON model combines an illuminated pushbutton head with a pre-installed LED module for enhanced visibility in low-light or high-risk zones. Ideal for outdoor environments or control rooms requiring fast status checks, this unit features:

- A durable enclosure with dust ingress protection

- Long-life LED lighting

- Compatibility with standard contact blocks

This model supports plug-and-play contact blocks, simplifying maintenance and reducing downtime.

STOI_C008 SHORTRON Momentary Pushbutton

The STOI_C008 SHORTRON is a rugged momentary pushbutton suitable for demanding industrial tasks. Used frequently in machine jog/start applications, it features:

- A tactile push mechanism

- IP-rated housing for protection against electrical hazards

- Compatibility with single contact block or double contact block configurations

This model is also available in multiple colours for easy control identification in multi-function panels.

Product Information and Retail Options

Venus Automation offers a wide range of pushbutton contact blocks and accessories, including:

- Emergency stop contact blocks

- Push button light blocks for illuminated control setups

- Silver-alloy and brass contact options

- Models tailored for panel mount, surface mount, or modular pushbutton assemblies

Whether you’re sourcing a single-pole contact block for a basic circuit or a complex, multi-contact solution for equipment in extraction systems, we can supply original, high-quality components.

For availability, specifications, and retail pricing, visit our product listings or contact our sales team directly.