IDEM non-contact safety switches are designed to ensure reliable machine safety without physical contact, reducing wear and maintenance in industrial environments. These devices use magnetic…

IDEM non-contact safety switches are designed to ensure reliable machine safety without physical contact, reducing wear and maintenance in industrial environments. These devices use magnetic or RFID-coded actuation to monitor the position of safety guards, access doors, and hatches, instantly halting machinery when safety boundaries are breached. At Venus Automation, we offer a broad selection of IDEM safety interlocks tailored for critical sectors such as food processing, pharmaceuticals, packaging, and automotive manufacturing, where precision, hygiene, and durability are essential.

Versatility and Applications of IDEM Switches

Machine Safety and Tamper-Proof Protection

IDEM’s RFID and magnetic safety switches are engineered to safeguard workers and equipment in automated environments. Their coded designs prevent bypassing or manipulation, making them ideal for robotic cells, CNC machines, and automated conveyors. Integration with machine safety relays or safety PLCs enables comprehensive safety logic.

Implementation in IP69K Environments

For environments with strict hygiene standards—such as food production, pharmaceutical labs, and chemical processing—IDEM offers IP69K-rated non-contact switches. Products like the MMC-H series are constructed from stainless steel and feature hermetically sealed designs that withstand high-pressure, high-temperature washdowns.

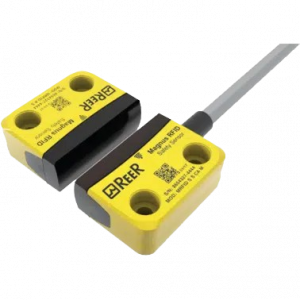

Understanding RFID Safety Switches

Features of RFID Safety Switches

IDEM RFID safety switches incorporate coded actuation, where each actuator is uniquely identified by the switch. This tamper-resistant design ensures only authorized access, improving personnel safety. These switches come with LED diagnostics, high tolerance to misalignment, and models that meet the highest IP69K hygiene standards. Stainless steel housings are available for aggressive washdown and cleanroom applications.

Benefits of RFID Over Traditional Switches

RFID switches offer advanced safety features not found in mechanical systems. They provide contactless operation, which minimizes mechanical degradation and reduces maintenance. Unlike generic magnetic switches, RFID models ensure high-level coding (PLe per ISO 13849-1), reducing the chance of defeat. They support flexible actuator alignment, making them ideal for complex machine geometries.

Understanding Magnetic Safety Switches

Characteristics of Magnetic Switches

Magnetic non-contact switches by IDEM, including the MPR, SPR, and WPR series, use magnetic fields to detect door and guard positions without mechanical contact. They offer simple installation, excellent misalignment tolerance, and resistance to vibration. These switches are suitable for Category 4 systems and can be configured in series for multiple access points.

Integration in Automated Systems

Magnetic switches are often chosen for light to medium-duty applications due to their affordability and reliability. They integrate easily into packaging lines, material handling systems, and light industrial equipment, especially where space constraints and environmental challenges are presents.

Key Advantages for Machine Protection

Allen-Bradley switches are reliable for standard environments but may fall short in demanding or hygienic applications. IDEM offers superior alternatives with higher IP ratings, coding security, and better integration with advanced safety systems like programmable safety relays and configurable logic controllers.

Advanced Safety Features

Solenoid-Controlled Guard Locking

IDEM’s range includes models with solenoid-controlled guard locking, ensuring that safety doors remain locked until all hazardous motion has ceased. This feature is critical in preventing accidental access during machine rundown or active processes.

Emergency Stop Functions

Some non-contact switches integrate emergency stop buttons or work alongside emergency circuits, enabling rapid machine shutdowns. This function is vital in high-risk environments where fast reaction time can prevent injury.

Programmable Safety Control Systems

IDEM non-contact switches are compatible with programmable safety controllers, such as IDEM’s own CM9 control modules or third-party safety PLCs. This allows users to configure complex safety zones, monitor switch status in real-time, and implement diagnostics and fault tolerance.

Current Trends in Safety Switch Technology

Enhancements in Safety Standards

As global standards evolve, IDEM continues to lead with products certified to ISO 13849-1, EN 60947-5-3, and IEC 61508. Their RFID and magnetic switches consistently meet PLe and SIL3 safety ratings, ensuring that they align with the latest compliance requirements for machine builders and OEMs.

Innovations in Industrial Automation

The shift toward Industry 4.0 has spurred IDEM to incorporate smarter diagnostics, connectivity options, and predictive maintenance capabilities into their switches. Whether it’s RFID-coded switches for access control or network-compatible safety modules, IDEM continues to push boundaries in automation safety.

Looking for high-performance, tamper-proof safety switches? Discover the IDEM range at Venus Automation—your trusted source for reliable machine safety solutions tailored for today’s industrial challenges.

Engineered for Flexible Connection Types and Industrial Demands

IDEM non-contact safety switches are designed with a variety of connection types to suit different installation needs, including M12 plug connectors, pre-wired cable options, and terminal block configurations. This flexibility ensures seamless integration into both new and legacy safety systems.

Many models come in plastic housing, offering a lightweight and cost-effective alternative to stainless steel versions. These plastic enclosures are highly durable and resistant to impact, making them suitable for standard industrial applications where hygiene or corrosive exposure is not a concern.

With a wide switching voltage range—typically supporting 24VDC and up to 240VAC depending on the model—IDEM switches can be reliably deployed across various control systems. Whether you’re working in automated packaging lines, assembly stations, or light-duty conveyors, these switches ensure safety compliance without sacrificing efficiency.

From robust plastic designs to configurable connection types and high switching voltage tolerance, IDEM’s non-contact safety switches deliver dependable performance in a wide range of industrial settings.

Broader Integration with Safety & Automation Systems

In modern industrial environments, IDEM Non-Contact switches are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs or safety relays, safety contactors and safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate locking devices such as mechanical interlock switches or solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.