Safety relays are essential components in industrial automation systems, acting as the control interface between safety devices and machinery. IDEM safety relays are specifically designed…

Safety relays are essential components in industrial automation systems, acting as the control interface between safety devices and machinery. IDEM safety relays are specifically designed to monitor safety inputs—such as emergency stop buttons, interlock switches, and light curtains—and trigger a safe shutdown in the event of a fault or hazardous condition.

How IDEM Safety Relays Ensure Machine Safety

By continuously supervising safety circuits, IDEM safety relays help ensure personnel protection and machine reliability. Their internal force-guided contacts guarantee fault detection, allowing critical machinery to stop immediately when a risk is detected. These relays meet global safety standards such as IEC 61508 (SIL) and ISO 13849-1 (PL), offering reliable fail-safe functionality.

Key Benefits of Using IDEM Safety Relays

-

Fast response time for emergency stops

-

Supports both manual and automatic reset modes

-

Dual-channel operation for redundancy

-

Ideal for Category 4 safety systems and PL d/e applications

-

Compact, DIN rail-mounted designs for easy integration

Types of IDEM Safety Relays Available

Dual Channel and Single Channel Relays

IDEM offers both single-channel and dual-channel safety relays to meet the redundancy and diagnostic requirements of various applications. Dual-channel relays are particularly suited for systems requiring higher performance levels (PL e) and enhanced fault tolerance.

Emergency Stop Safety Relays

IDEM emergency stop relays are designed for immediate power isolation when an e-stop button is pressed. These relays are optimized for use with Category 4 emergency stop systems, providing fast and reliable actuation for conveyor systems, robotics, and other high-risk equipment.

Time Delay and Monitoring Relays

Some IDEM models include a built-in time delay function, ideal for controlling the delayed shutdown of machinery or staged power-off sequences. Monitoring relays also check input status, wiring integrity, and contact conditions to prevent unsafe operations.

Force-Guided Contact Relays

These relays include mechanically linked contacts that prevent simultaneous welding of normally open and normally closed contacts, ensuring safe feedback in control circuits.

Technical Features of IDEM Safety Relays

Manual and Automatic Reset Options

IDEM relays offer flexible reset configurations, including automatic, monitored manual, and key-reset functions. This ensures compliance with specific safety protocols across various industries.

SIL and Performance Level Ratings

Each IDEM safety relay is tested to comply with the strictest safety levels—meeting SIL 3 requirements under IEC 61508 and performance level e under ISO 13849. This makes them suitable for critical applications in high-risk zones.

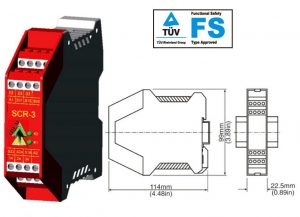

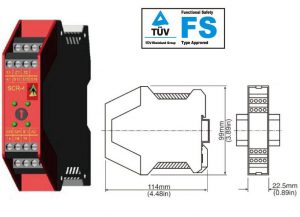

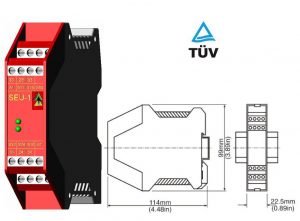

Compact DIN Rail Mounting Designs

Engineered with space efficiency in mind, IDEM safety relays are compact and DIN rail-mountable, making them ideal for crowded control panels and modular automation systems.

Compatible Voltages and Connection Types

Available in a variety of input voltage ranges (typically 24V DC or AC), IDEM relays are also equipped with standard connection options, including screw terminals and M12 plug connectors for simplified installation.

Industrial Applications of IDEM Safety Relays

Safety Relays for Conveyor and Packaging Systems

IDEM safety relays are widely used in conveyor and packaging lines, where emergency stops and safety interlocks are critical to prevent injury and equipment damage during high-speed operation.

Integration in Robot and CNC Machines

In robotic and CNC machine environments, IDEM relays help maintain operator safety during tool changes, maintenance, and error conditions. They are often integrated into safety controllers and light curtain systems for rapid fault response.

Machine Guarding and Interlock Control

Machine guarding systems benefit from IDEM’s monitored safety relays by enabling controlled access and safe system shutdown when guards are opened or tampered with. Their compatibility with interlock switches simplifies circuit design.

Integrating IDEM Safety Relays with Your System

Compatibility with Safety Light Curtains and Switches

IDEM relays are designed to work seamlessly with light curtains, safety sensors, and mechanical interlock switches. This allows engineers to design robust safety circuits using a unified product ecosystem.

Wiring into Safety PLCs and Control Panels

Whether integrating into a simple control panel or a sophisticated safety PLC, IDEM safety relays ensure flexible and reliable signal processing. Pre-configured wiring diagrams and labeled terminals make installation fast and error-free.

Using M12 Connections for Quick Installation

M12 plug connectors reduce wiring complexity and allow for faster relay swaps or panel upgrades. This makes IDEM relays especially useful for modular automation systems where downtime needs to be minimized.

Why Choose IDEM Safety Relays?

Compliance with International Safety Standards

IDEM safety relays are globally certified and compliant with IEC, ISO, and EN safety standards. They are trusted across the automotive, food processing, pharmaceutical, and packaging industries for reliable machinery protection.

Durable, Tamper-Resistant Design

With robust housing and tamper-proof reset mechanisms, IDEM relays are built for demanding industrial environments. Their resistance to vibration, dust, and electrical interference ensures long-term reliability.

Trusted by Engineers Across Industrial Sectors

Backed by a strong reputation in the automation industry, IDEM has become a preferred brand for engineers designing safety systems that require dependable performance and easy integration.

Frequently Asked Questions (FAQs)

What is a dual-channel safety relay?

A dual-channel safety relay monitors two independent inputs for redundancy, ensuring that faults are detected even if one channel fails—ideal for PL e or SIL 3 applications.

How do I wire an emergency stop to a safety relay?

Connect the e-stop button’s contacts to the relay’s input terminals. IDEM relays provide clear wiring diagrams and support both normally closed (NC) and monitored contact configurations.

Are IDEM safety relays compatible with my control system?

Most likely, yes. IDEM relays support standard 24V control voltages, screw or M12 terminals, and are compatible with most industrial safety controllers and PLCs.

Broader Integration with Safety & Automation Systems

In modern industrial environments, IDEM’s safety relays are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety non-contact switches, RFID switches, and other mechanical interlock switches or solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.