Euchner’s Mounting Solutions Overview Euchner offers a comprehensive range of mounting accessories designed to support safe, reliable, and efficient installation of their advanced safety switch…

Euchner’s Mounting Solutions Overview

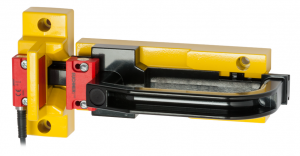

Euchner offers a comprehensive range of mounting accessories designed to support safe, reliable, and efficient installation of their advanced safety switch systems. These solutions include mounting plates, brackets, and hardware engineered for compatibility with a wide range of devices such as MGB handle modules, CES-C01 safety switches, and CEM-A-LE05 read heads. Euchner mounting accessories are widely available in Australia, the USA, the UK, and Germany through authorized distributors and online stores. Product documentation includes declarations of conformity, mechanical values, and multilingual safety information (Informazioni sulla sicurezza / Sigurnosne informacije).

Importance of Accurate Mounting for Safety Switches

Accurate mounting is essential to ensure the optimal performance and longevity of safety switches. Improper installation can compromise the operational condition of the device, increase maintenance frequency, and reduce safety relay response time. Euchner’s purpose-built mounting accessories eliminate these risks by offering stable, robust support tailored for each product model, and conforming to mechanical values, insulation voltage tolerances, and detailed safety specifications.

Types of Euchner Mounting Solutions

Mounting Plates

Products like the EMP-L-CEM05 and MGB-A-MOUNTINGPLATE-H-109491 provide secure platforms for read heads and MGB2 modules. These include the plate for evaluation modules and support various actuator for safety switch configurations. They are constructed from durable materials such as aluminum or steel plate material and ensure vibration resistance and impact energy absorption.

Mounting Brackets

Euchner’s mounting brackets are suitable for right- and left-hinged doors. Designed for fast, two-screw installation and quick module replacement, they provide a reliable option for industrial environments with mechanical life requirements exceeding millions of insertion cycles.

Mounting Hardware

This category includes adjustable clip holders like MP-A-C-CH-00-00-157842 and plug connectors. Included are color-coded components (e.g., color black), screws per actuator, CAGE CLAMP terminals, and connection material types for aluminum standard profiles and automation technology frameworks.

Key Features of Euchner Mounting Accessories

Compatibility with Safety Switches

Euchner mounting solutions are fully compatible with CES, CEM, and MGB safety systems, including transponder-coded safety switches and switches with guardlocking. They support B1 for actuators, hinged actuators, and advanced actuator alignment in multifunctional gate box assemblies.

Robust Installation Features

Accessories feature reverse polarity protection, vibration resistance, impulse voltage stability, and position with padlocks. Most units are rated with degree of protection (IP ratings), specified insulation voltage (UB-2V … UB V DC), and current parameters such as current of 50mA.

Customization Options

Euchner offers product version flexibility and includes documentation such as declarations of conformity and original packaging. Slide-in labels, label carriers, adhesive labels, and support for factory seal status are all included in the scope of delivery.

Technical Specifications

Dimensional Drawings

Detailed dimensional drawings outline bolt placements, cable entry points, output type configurations, and contact block settings. These also define connection cross and slide-in label positions for accurate and efficient mounting.

Mechanical and Structural Integrity

Products are tested for switching frequency, mechanical values, mechanical life, load on outputs, and degree of contamination. Mounting systems meet IEC 60947-5-3 max thresholds and have defined discrepancy time and risk time limits.

Integration with Safety Systems

Compatibility with Industry Standards

Euchner accessories integrate with systems designed to meet EN ISO 13849-1, EN IEC 62061, and IEC 60947-5-3. They support safety outputs FO1A, monitoring outputs, closed-circuit current principle configurations, and locked position monitoring.

Enhancing Workplace Safety and Efficiency

Solutions support quick mounting, position by spring force, auxiliary releases, and automatic lockout mechanisms. They allow guard lock monitoring and status checks for energized guard conditions using visual indicators and plug-in modules.

Installation Guidelines and Best Practices

Preparing for Installation

Verify product version, read operating instructions for safety systems (e.g., MGB-L1), and ensure matching declarations of conformity. Check insulation voltage, cable lengths, plug connector types, and auxiliary jumper position before installation.

Step-by-Step Installation Process

- Align the mounting plate using dimensional drawings.

- Attach securely using screws per actuator.

- Confirm insulation voltage and output current.

- Mount actuator and ensure proper locked position alignment.

- Complete test cycle to confirm correct switching current and operational functionality.

Benefits of Using Euchner Mounting Solutions

Improved Operational Safety

Guard lock monitoring, auxiliary contact compatibility, monitoring outputs, and average response time metrics ensure safe and reliable machine operation in challenging industrial safety environments.

Increased Efficiency

Thanks to quick module replacement, hinged actuator support, and compatibility with control module systems, installation and maintenance are streamlined across automation panels and industrial safety infrastructure.

Related Accessories and Their Uses

Actuator Types and Their Roles

Euchner supports a full range of actuators for safety switches, including extended actuation axis options, bolt for safety switch configurations, and auxiliary release for emergency override access. Many devices utilize a closed-circuit current principle.

Additional Safety Components

Accessories include locking arms, fold-out lockout mechanisms, status indication modules, and optional accessories like angled plug connectors. These features contribute to modular, secure industrial safety installations.

Compliance with Industry Standards

EN ISO 13849-1

Mounting accessories comply with ISO 13849-1 through validated risk time, output type, average response time, and mechanical performance metrics. Product lifecycle and auxiliary release options are detailed in compliance documentation.

EN IEC 62061

All Euchner mounting solutions meet EN IEC 62061 design criteria, including protection against inductive loads, impulse voltage, and safety signal switching. Safety information, Informazioni sulla sicurezza, and Sigurnosne informacije are all included in multilingual datasheets.