Electrical terminals play a key role in ensuring a secure connection within a variety of electrical systems, such as relays, safety PLCs, light curtains or…

Electrical terminals play a key role in ensuring a secure connection within a variety of electrical systems, such as relays, safety PLCs, light curtains or emergency stops. Found in both residential and industrial setups, these components serve as essential interfaces for connecting electrical conductors to devices or circuits. The wide array of electrical terminals available today supports everything from circuit boards and control cabinets to junction boxes and motorised control units.

Types of Electrical Terminals

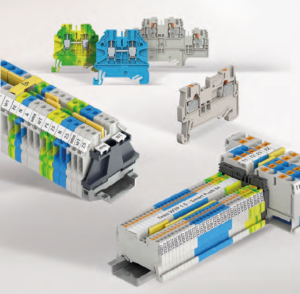

There is an extensive range of electrical terminals designed for different applications. Common types include ring terminals, spade terminals, blade terminals, and push-on terminals. Rail terminal blocks, particularly those offering push-in connection and pluggable terminal blocks, are commonly used in industrial environments due to their ease of wiring and support for a wide range of wire sizes. Specialized options like triple-deck terminal blocks and single-level, screw termination designs offer maximum flexibility for complex electrical systems.

Applications of Electrical Terminals

Industrial Uses

In industrial environments, electrical terminals are critical for signal distribution, power management, and automation. Terminal blocks ensure a reliable connection across equipment, while features such as jumper bars and ground terminals support modular expansion and circuit identification. Rail screw terminal blocks and multi-conductor connection types streamline installation in control cabinets and switchboards.

Home and Residential Uses

Within residential systems, electrical terminals simplify connections in lighting systems, home automation circuits, and junction boxes. Their compact design and secure connection are particularly valuable for integrating light curtains or supporting the installation of small circuit boards.

DIN Rail Terminal Blocks: An Organizing Solution

Features and Benefits

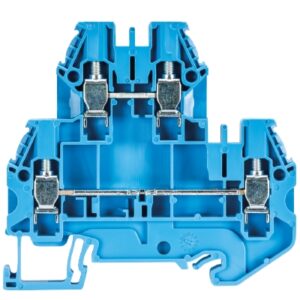

DIN rail terminal blocks are engineered to offer reliable performance and secure connections. Their modular design allows for maximum flexibility in organizing wiring for control panels and distribution boxes. These terminal blocks support push-in termination, screw connection, and advanced connection technologies that are compatible with a wide range of wire sizes and circuit boards.

Installation and Maintenance

Installation is simplified with push-in connection systems and jumper bar compatibility, while partition plates aid in maintaining clarity and circuit identification. These rail terminal blocks also support ease of wiring, making them ideal for projects requiring repeatable and scalable solutions. Engineering software can be used for layout planning, minimizing errors during assembly.

Key Manufacturers: Wieland Electric

Wieland Electric is a prominent manufacturer known for its innovative rail terminal blocks, ground terminals, and accessories. Their product range includes compact, durable components that support motorised control, signal distribution, and various pluggable terminal block formats. Wieland’s country of origin certification and engineering tools make it a reliable choice for both standard and custom installations.

Understanding Electrical End Plates

Importance for Structural Integrity

End plates are vital accessories in terminal block assemblies. They close off open sides of terminal blocks, maintaining the structural integrity of the electrical circuit and preventing accidental contact. This is especially important in complex setups that use triple-deck terminal blocks or multi-conductor configurations.

Safety Considerations

End plates improve overall system safety by shielding live components. When used in conjunction with other accessories like partition plates and rail brackets, they ensure a safer environment in both industrial and residential electrical systems.

The Role of Plastic End Brackets

Enhancing Stability in Setups

Plastic end brackets serve as anchors on DIN rails, preventing terminal blocks from shifting during operation or maintenance. They are essential for installations that demand a reliable connection over time, especially in environments exposed to vibration or mechanical stress.

Material and Design Variations

These brackets come in a wide range of materials, with nylon being a popular option due to its insulating properties and mechanical strength. Depending on the application, users can select brackets designed for compact installations or those supporting a broader range of accessories and connection technologies. Plastic end brackets also contribute to neat and structured wiring layouts, an essential factor in achieving reliable performance across all electrical systems.

Broader integration with Safety & Automation Systems

In modern industrial environments, Terminals are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, under voltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.