ATEX Traditional Light Fixtures for Hazardous Areas Proven Explosion-Proof Lighting for Gas and Dust Environments In hazardous environments, lighting must deliver reliable visibility without…

ATEX Traditional Light Fixtures for Hazardous Areas

Proven Explosion-Proof Lighting for Gas and Dust Environments

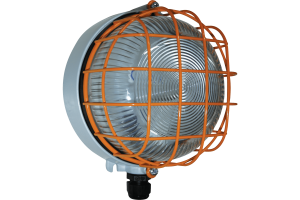

In hazardous environments, lighting must deliver reliable visibility without introducing ignition risk. ATEX traditional light fixtures are designed for use around flammable gases, vapours, volatile chemicals, and combustible dust, where mechanical strength, sealed construction, and long service life are essential.

These explosion-proof luminaires remain widely specified in corrosive, high-risk, and legacy industrial environments where durability, certification, and predictable performance matter more than form factor.

Where ATEX Traditional Light Fixtures Solve Real Problems

Traditional ATEX luminaires are commonly used where lighting must survive mechanical stress, washdowns, vibration, and temperature extremes, including:

- Chemical and petrochemical processing areas

- Tank farms, loading bays, and gas stations

- Heavy industrial plant rooms and utilities

- Confined spaces and enclosed production zones

- Sites upgrading gradually from fluorescent to LED systems

They provide dependable illumination in locations where failure directly impacts safety.

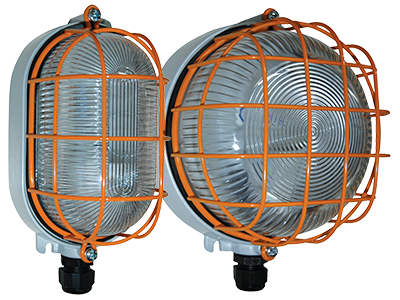

Explosion-Proof Lighting Fixtures & Typical Applications

Explosion-proof lighting fixtures are engineered so that internal faults, arcs, or thermal events remain fully contained, preventing ignition of the surrounding atmosphere.

Common fixture types include:

- Area lights for open processing zones and access corridors

- Flood lights for yards, perimeters, and equipment areas

- High-bay lighting for tall industrial buildings

- Low-bay fixtures for skids, workshops, and enclosed spaces

- Explosion-proof linear lights along walkways and conveyors

In mixed installations, traditional fluorescent or linear luminaires are often retained alongside newer LED fixtures to maintain consistent light distribution.

Hazardous Area Classification & Zoning

Correct selection starts with hazardous area classification:

- Zone 1 – Explosive atmospheres likely during normal operation

- Zone 2 – Explosive atmospheres unlikely and short-duration

- Zone 0 – Continuous presence of explosive gases

- Zone 20 / 21 / 22 – Combustible dust hazards

Some global sites also reference Division-based classifications, requiring fixtures that align with multiple compliance frameworks.

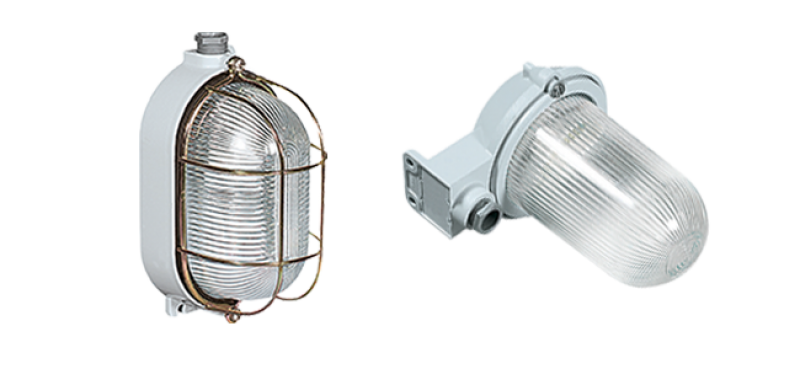

Traditional Technologies, Thermal Control & Reliability

While LED dominates new installations, traditional hazardous-area luminaires remain common where infrastructure continuity or maintenance strategy dictates.

Key performance features include:

- Controlled surface temperature

- Robust thermal management

- Sealed optics and gasket systems

- High ingress protection, typically IP66 / IP67

- Impact-resistant housings for harsh environments

These characteristics ensure stable performance under continuous operation and aggressive cleaning regimes.

Installation, Mounting & Safety Considerations

Maintaining ATEX certification depends on correct installation.

Typical options and requirements include:

- Wall, ceiling, bracket, pole, or suspension mounting

- Beam angle and lumen selection matched to task lighting

- Emergency or battery backup where required

- Correct gland, conduit, and hub sealing

- Clear labelling and safety warnings for confined spaces

Incorrect mounting or cable termination can invalidate certification.

Engineer-Focused Selection Guide

When specifying ATEX traditional light fixtures, engineers should confirm:

- Hazardous area zone (Zone 1, 2, 20, 21, 22)

- Gas group or dust classification

- Temperature class (T-rating)

- Fixture type (area, flood, high-bay, low-bay, linear)

- Ingress protection rating for washdown or outdoor use

- Mounting method and mechanical strength

- ATEX / IECEx certification and supporting documentation

If zone rating, T-class, or installation requirements are unclear, the fixture should not be used in a hazardous area.

Reliable Lighting for Hazardous Locations

ATEX traditional light fixtures are proven safety components, not generic industrial luminaires.

Specified correctly, they deliver durable construction, controlled thermal performance, and certified explosion protection, supporting safe operations across gas and dust hazardous environments.

If a fixture lacks clear ATEX approval, defined zone suitability, or compliant installation data, it does not belong in a hazardous location.