27

E-Stop Troubleshooting 101: Workplace Safety

E-Stop Troubleshooting 101: Workplace Safety

In industrial automation, safety takes precedence to protect lives and processes. Understanding the nuances between safety contactors and standard contactors is crucial in ensuring the utmost safety and reliability. In this blog post, we’ll delve into the key distinctions and applications of safety contactors and standard contactors, emphasizing safety automation and design principles.

Emergency stop systems, or Emergency Stops, play a crucial role in preventing accidents and ensuring workplace safety. However, like any safety mechanism, E-Stops can sometimes fail or malfunction, leading to potential hazards. Proper troubleshooting of Emergency Stop Buttons is essential to maintaining a safe and compliant work environment.

Common issues with E-Stops include worn-out E-Stop Push Button Heads, faulty Push Button Contact Blocks, and improper wiring. In some cases, the problem might stem from a damaged Coloured Lens or a misaligned Stop Head, affecting visibility and functionality.

To troubleshoot effectively, start by inspecting all physical components, including the Rope Pull Emergency Stops and related accessories. If the issue persists, checking the control circuits and testing continuity in contact blocks can help identify the fault. Implementing a structured troubleshooting approach ensures that emergency stop systems remain operational, reducing downtime and maintaining workplace safety.

Understanding the Emergency stop Button

An emergency stop button, or E-Stop, is a safety switch that quickly halts machinery to prevent injuries or workflow disruptions. E-stops are essential safety components in various industries, instantly stopping machines when activated. They feature a recognizable red button with a yellow background for quick identification. They should be used whenever there’s a risk of injury or the need to stop machinery fast, such as equipment malfunctions, operator errors, or unexpected hazards, enhancing safety in industrial, commercial, and public spaces.

Common E-stop Problems

Wiring and Connection Issues

The most common wiring error is cross wiring the test pulses in to e-stop inputs.

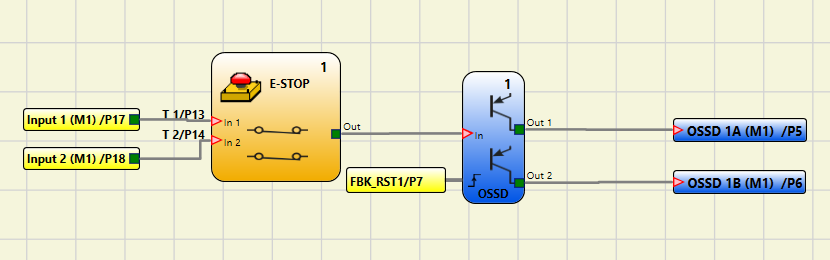

We’ll use the below example to explain this. Nelow is an implementation of a dual channel estop with a ReeR M1 MOSAIC Safety PLC System. With:

Inputs: PIN 17 & 18

Test Outputs: PIN 13 & 14

Safety OSSD Outputs: PIN 5 & 6

Reset: PIN 7

What is cross wiring?

Cross wiring is when the incorrect test pulse is wired to the incorrect input in resulting in the machine not turning on (Green light on). This can be identified by the flashing yellow/orange lights on the M1 inputs 1 and 2.

Following the example above, test pulse from PIN 13 incorrectly goes into Input PIN 18, and test pulse from PIN 14 incorrectly goes into Input PIN 17.

PIN 13 → PIN 18

PIN 14 → PIN 17

.

Once correctly wiring the system, the estop should work as normal.

PIN 13 → PIN 17

PIN 14 → PIN 18

.

Other Possible Issues

Faulty/Broken Safety Relay or PLC

In certain situations, the reliability of an emergency stop (E-stop) system can be compromised when the safety relay or programmable logic controller (PLC) becomes faulty or damaged, necessitating replacement.

imProper Connection

Occasionally, the effectiveness of an emergency stop (E-stop) system can be compromised when the E-stop button head is improperly connected to the contact block. This vital interface ensures that when the E-stop button is pressed, it effectively breaks the electrical circuit, halting machinery and equipment.

Software of Control System Issues

In complex machinery with integrated control systems or PLCs, adjustments or reprogramming of the safety system may be necessary to ensure proper E-stop functionality, as issues within the software or programming logic can hinder the E-stop reset process.

E-stop button Damaged

The E-stop button is crucial for safety in industrial applications and should be inspected periodically for physical damage or wear to ensure it functions properly. Malfunctions are often caused by damage or wear to the button/device. Inspect for cracked or warped components and proper connection/functioning. Taking proactive measures ensures the E-stop system is ready to serve its safety function.

Figured Products

MOSAIC M1

Wieland Emergency Stop

Wieland Power Supply

Building a Reliable Emergency Stop System with Advanced Monitoring

Troubleshooting emergency stop systems is only one aspect of maintaining a safe working environment. To ensure complete functional safety, emergency stop devices must be part of a broader architecture that reliably monitors safety inputs and triggers appropriate outputs during faults or hazards.

A key component in modern safety systems is the safety PLC. These programmable devices allow custom safety logic, with flexible input/output terminal assignments. Venus Automation offers a variety of models, including the MOSAIC PLC from Reer, Samos PLC from Wieland, and GEMNIS PLC from Pizzato—each delivering advanced and reliable safety functionality.

Where complex programmability is unnecessary, alternative options such as the safety relay range are available. This includes standalone relays, time-delay relay, speed-monitoring relay, standstill monitoring and timer, PCB relay, relay expansion modules, and control relays like the emergency stop relay, safety edge relay, light curtains relay, and two-hand control relay. These options provide effective and application-specific safety responses.

Essential manual inputs such as the emergency stop remain integral to any safety architecture, despite lacking an automatic safety input. Venus Automation supplies complete solutions including emergency stop accessories, pushbuttons, two-hand stops, and specialized devices like the rope pull emergency stop. For modern installations, wireless safety systems, including wireless emergency stop units, remote controls and accessories, are also available.

Critical integration elements such as contact blocks are supplied to ensure seamless circuit connections. Additional safety monitoring components include the safety encoder, which monitors motor speed, and interlock devices such as tongue solenoid interlock switch and electro-magnetic switches. For more complex safety guarding, multifunctional gatebox units provide a consolidated interface, easily mounted on protective enclosures like concertina guards.

Access restriction and control can also be achieved through electronic key systems, ensuring machinery operates only under authorized conditions. Finally, for output-side protection, safety contactors and pneumatic safety valve solutions are available to ensure reliable machine stoppage when hazardous conditions are detected.