Introduction to Variable Speed Drives (VSDs) Variable Speed Drives (VSDs) are electronic systems used to regulate the rotational speed and torque of electric motors by…

Introduction to Variable Speed Drives (VSDs)

Variable Speed Drives (VSDs) are electronic systems used to regulate the rotational speed and torque of electric motors by adjusting the power supplied. These drives are essential in modern automation, helping match motor speed to real-time demand across industrial, commercial, and residential sectors. VSDs support improved energy efficiency, smoother operation, and lower mechanical wear, making them a key technology in both new installations and retrofits.

How Variable Speed Drives Work: Process and Control

VSDs operate by converting a fixed-frequency AC input into a variable voltage and frequency output, which controls motor speed. This process typically involves three stages:

-

Rectification of incoming AC power to DC.

-

Filtering the DC signal.

-

Inversion back to AC using a Voltage Source Inverter (VSI).

By adjusting the output voltage and frequency, VSDs provide precise control over motor performance. Control inputs—whether analog signals, digital commands, or feedback from sensors—allow the drive to automatically optimize motor speed for changing system loads.

Types of Motors and Pumps Compatible with VSDs

VSDs are compatible with a wide range of AC motors, including single-phase and three-phase induction motors. When applied to pump systems, VSDs improve responsiveness and reduce the need for mechanical throttling. They are especially effective in:

-

Centrifugal pumps

-

Fan systems

-

Positive displacement pumps

-

Conveyors and mixers

These drives also support closed-loop control, responding dynamically to feedback such as flow rate, pressure, or load torque—ensuring constant operation within acceptable performance limits.

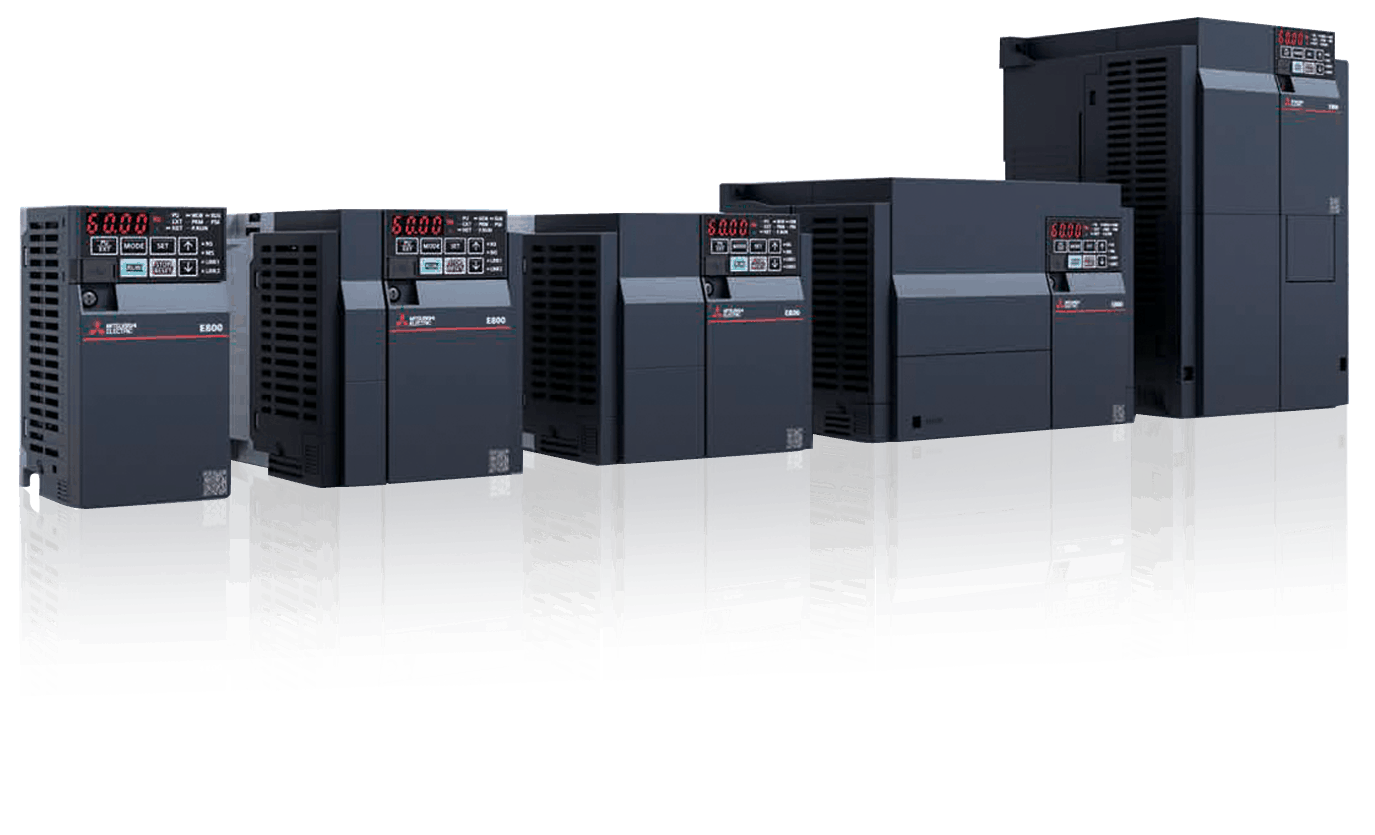

Mitsubishi Variable Speed Drives (VSDs): Efficiency, Control, and Innovation

Mitsubishi Electric’s FR-D700 series — including the FR-D720, FR-D720S, and FR-D740 models — represent compact, reliable, and energy-efficient Variable Speed Drives (VSDs) trusted across industrial, commercial, and residential sectors. With support for both single- and three-phase AC motors ranging from 0.4kW to 7.5kW, these drives deliver advanced motor speed control, high-performance features, and seamless integration into new or retrofit applications. Mitsubishi drives are engineered to accommodate various current ratings, operate within strict acceptable limits, and maintain system performance even in demanding environmental and electrical conditions. With reduced annual energy consumption and optimal power characteristics, they support long-term system efficiency.

What Makes Mitsubishi VSDs Stand Out?

Mitsubishi’s FR-D700 series combines the precision of Variable Frequency Drives (VFDs) with a user-friendly interface and advanced control technology. These drives use Voltage Source Inverter (VSI) topology to convert incoming AC power into a variable output frequency and output voltage, ensuring accurate speed control, constant torque, and responsive torque handling. Integrated features like dynamic braking, acceleration control, carrier-frequency pulsed output voltage, and support for control signals via Modbus/RS485 make them ideal for responsive automation environments.

They also support automatic frequency control, adapt to variable-speed loads, and are built with strong resilience to voltage distortion, AC line current waveform inconsistencies, and grounding practices challenges in complex installations. The ability to provide an optimized output signal and handle electrical stress under varying operating conditions further improves system safety and motor longevity.

Applications of Mitsubishi FR-D700 Series VSDs

Mitsubishi VSDs are designed to adapt to changing load requirements and provide efficient solutions across a wide range of drive applications:

Industrial Applications

- FR-D720-3.7K and FR-D740-080-EC are ideal for conveyor belts, injection moulding machines, belt drives, and other industrial motors, offering constant torque, reduced electrical stress, and optimized process flow. They also integrate well with induction motors, wound-rotor synchronous motors, and advanced factory automation systems.

Commercial Applications

- FR-D740-036-EC and FR-D720S-1.5K-EC are commonly used in HVAC systems, escalators, and water booster stations, helping reduce start-up spikes and optimizing fan applications and compressor applications. When paired with pressure or flow sensors, these drives support load-adaptive performance and digital services such as energy analytics and preventive maintenance.

Residential Applications

- FR-D720S-0.75K-EC and FR-D720S-0.4K-EC are suited for pressure boosting, solar water pumps, and energy-efficient fans, enabling quiet, stable motor operation, consistent motor speed, and reduced power usage. These units can be adapted for single pump systems and benefit from adjustable speed controller integration.

These drives are also well-suited for blower applications, flow rate modulation, and systems requiring continuous operation across a broad range of speeds.

Energy Efficiency and Cost Savings

With support for affinity laws, Mitsubishi VSDs enable facilities to reduce electrical power and energy consumption dramatically. For example, reducing motor speed by 20% can result in nearly 50% energy savings in centrifugal pump applications. Combined with lower repair costs, reduced operating costs, and fewer component failures, these drives typically provide a financial payback within 12–24 months.

VFDs like the FR-D740-160-EC contribute to measurable reductions in price of energy usage and mechanical power output losses. Additionally, digital services provide visibility into current flow, voltage variable settings, and energy efficiency metrics. These features are particularly useful in facilities where reducing annual energy consumption is critical for compliance and cost control.

Motor Speed Control Across a Wide Operating Range

Thanks to their ability to control rotational speed, base speed, and even operate near synchronous speed, Mitsubishi VFDs eliminate the need for mechanical throttling. Whether through manual speed adjustment, digital pre-sets, or automated PLC integration, the FR-D700 series ensures smooth and efficient motor performance — even under dynamic or fluctuating conditions. Drives also feature advanced capabilities for handling rush current, load torque, variable torque, and frequent acceleration, providing protection against excessive electrical stress.

The drives’ ability to manage power characteristics, such as variable power ratings, voltage levels, voltage variable inputs, and power factor, ensures long-lasting efficiency and compliance with grid quality standards.

Product Comparison: FR-D720 vs. FR-D720S vs. FR-D740

| Feature | FR-D720 | FR-D720S | FR-D740 |

|---|---|---|---|

|

Input Type |

3-phase 400V |

1-phase 230V |

3-phase 400V |

|

Power Range |

0.4kW–7.5kW |

0.4kW–2.2kW |

0.4kW–7.5kW |

|

Applications |

General-purpose |

Light-duty residential/commercial |

Industrial fans, pumps |

|

EMC Filtering |

Optional |

Built-in |

Built-in |

|

Harmonic Filtering |

Optional |

Standard |

Standard |

|

Smart Interface |

Basic |

Operator-friendly |

Full I/O + digital comms |

|

Voltage Distortion Control |

Optional |

Built-in |

Advanced filter enabled |

|

Fan Speed Compatibility |

Basic |

Indoor fans |

High-speed industrial fans |

Latest Mitsubishi Innovations in Drive Technology

Mitsubishi continues to advance drive technology with features such as:

- Synchronous reluctance motors for high-efficiency, low-loss operation

- Magnetic bearings for frictionless, wear-free performance in high-speed systems

- Bi-directional IGBT switching bridges for energy regeneration and four-quadrant operation

- Internet-enabled systems for smart control, remote monitoring, and digital services integration

- Active filters to manage harmonic distortion limits, reduce voltage distortion, and protect sensitive devices

- Wound-rotor synchronous motors compatibility for specialized industrial loads

- Inverter voltage optimization to deliver stable AC motor speed control with minimal ripple

These innovations position Mitsubishi VSDs as reliable tools in the evolution toward Industry 4.0, smart energy systems, and sustainable AC drive infrastructures.

Retrofitting and Motor System Optimization

Retrofitting older systems with Mitsubishi VSDs like the FR-D720-1.5K or FR-D740-050-EC improves energy efficiency, enhances real-time control, and reduces both mechanical stress and electrical stress. These drives are compact, easy to install, and support integration with programmable logic controllers, operator interface devices, and serial communications ports for seamless control upgrades.

Using Mitsubishi’s digital services, plant operators can also monitor electrical supply, track motor applications, analyse drive applications, and schedule firmware updates that ensure system compatibility with evolving production process demands. The drives can accommodate additional converter modules and advanced topologies like active infeed converters to enhance performance.

Best Practices: Motor and Pump Management

Right-Sizing Motors

Choose motors that closely match actual load torque and system performance using Mitsubishi’s drive selection calculators. Avoid oversizing to reduce inefficiency, voltage levels misalignment, and unnecessary electrical energy use.

VFD Selection for Pumps

For centrifugal pumps and positive displacement pump setups, use models like the FR-D740-120-EC for high-flow or variable-torque applications. Make sure the drive supports the right power ratings, voltage variable input, and external feedback from flow/pressure sensors.

Proper motor and VFD matching not only reduces electrical supply burden but also extends equipment service life, improves accurate control, and ensures optimal return on investment.

Maintaining Long-Term Drive and Motor Efficiency

Preserve peak efficiency with routine inspections:

- Monitor carrier-frequency pulsed output voltage and ensure safe thresholds

- Validate power waveform quality and clean grounding to prevent distortion

- Check drive cooling, cabling, and current input stability

- Ensure compatibility with the power supply, and monitor current flow, AC converter topologies, and heat recovery systems

- Detect potential 7th harmonics and waveform distortions using Mitsubishi’s on-board diagnostics

Mitsubishi’s drives come with built-in diagnostics, automatic control settings, and smart update capabilities, helping users maximize service life, minimize electrical motors degradation, and meet acceptable limits of energy usage.

Broader integration with Safety & Automation Systems

In modern industrial environments, VSDs are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, under voltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Explore Our Mitsubishi VSD Range

We stock a full range of Mitsubishi FR-D700 series drives, including:

- FR-D720, FR-D720S, and FR-D740 (0.4kW to 7.5kW)

- EC and non-EC versions with built-in EMC filters

- Drives optimized for fan speed, motor speed control, pump applications, and more

- Ideal for adjustable-speed drive requirements, compatible with three-phase motors, and suited to applications requiring precise AC motor speed control

- Ready to support automatic signal processing, AC drives, variable speed control, and advanced drive applications

Shop Mitsubishi VSDs now or contact us to find the right model for your system. For tailored support, performance comparisons, or retrofit planning, our technical team is ready to help you maximize control and efficiency with Mitsubishi Electric.