Metal body interlocks are robust safety devices designed to prevent access to hazardous areas of machines during operation. These mechanical safety interlock switches ensure safe…

Metal body interlocks are robust safety devices designed to prevent access to hazardous areas of machines during operation. These mechanical safety interlock switches ensure safe operation by requiring specific sequences or conditions to be met before allowing access. Their primary function is to protect personnel from accidental operation and to ensure the machine guard and safety doors remain securely locked until all safety conditions are met.

Components of Metal Body Interlocks

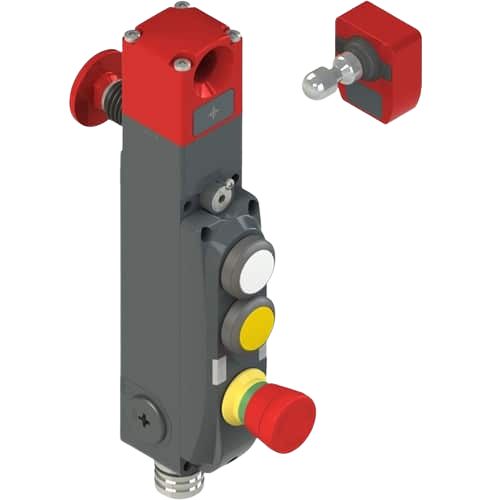

Typical components include a durable metal housing, actuator key, locking mechanism, and electrical contacts. The locking function relies on precise physical contact between the actuator and switch body, providing secure operation under various industrial conditions. Depending on the model, interlock devices may also incorporate solenoids, sensors, or RFID technology to enhance flexibility, various connection types, and customisable solutions suited to different control panels and control units.

How Metal Body Interlocks Work

Interlocking Mechanism

The interlocking mechanism uses either mechanical or electro-mechanical means to enforce specific safety protocols. When the machine is in operation, the actuator is locked in place, preventing the safety guard or safety gate from opening. Only once safe shutdown is confirmed can the locking mechanism be disengaged, ensuring continued protection in both normal conditions and harsh environments.

Sequencing Control

Metal body interlocks enable sequencing control, ensuring that tasks occur in a predefined order to maintain the level of safety. For example, in multi-zone manufacturing systems, certain safety doors must remain locked until upstream processes are safely completed, supporting compliance with machine safety standards and safe machine control.

System Override and Bypass Features

Some interlock switches include override or bypass capabilities for maintenance purposes, though these features are strictly governed by international standards. Validation purposes must be documented, and risk assessment protocols must be followed to avoid compromising the safety of personnel.

Broader Integration with Safety & Automation Systems

In modern industrial environments, metal bodied interlock switches are only one part of an integrated safety architecture. These switches will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations will frequently incorporate safety relays, safety non-contact switches, RFID switches, and possibly other mechanical interlock switch variants or solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Applications in Various Engineering Sectors

Manufacturing Industry

In manufacturing, metal body interlocks are used to secure access to machine tools, conveyors, and robotic cells. They help mitigate the risks of unexpected start-up and ensure worker safety in demanding industrial environments. These devices are essential components when dealing with dangerous machinery and machine control systems.

Automotive Sector

Within automotive plants, these safety interlocks are critical in areas involving stamping, welding, and painting. Their compact size and resistance to contamination make them ideal for clean environments and areas with rigorous machine operation sequences.

Chemical and Pharmaceutical Plants

Mechanical switches with high durability are essential in pharmaceutical manufacturing and chemical processing. These settings demand robust guard locking switch systems that perform reliably under strict hygiene and operational standards. Metal body interlocks here serve not only as mechanical interlock switches but also as crucial safeguards for physical guards.

Energy and Power Generation

In energy and power facilities, interlock devices play a vital role in ensuring secure operation of high-voltage equipment and turbines. Their role in safeguarding access points supports ongoing compliance with international safety standards and enhances safety of machinery in harsh environments.

Compliance with International Safety Standards

Key Safety Standards to Note

Metal body interlocks must align with key machine safety standards such as ISO 14119 (Safety of machinery – Interlocking devices) and ISO 13849 for the safety of personnel. These standards dictate design principles, performance levels, and functional requirements that apply to safety limit switches and mechanical interlock switches.

Certification and Testing Processes

Leading manufacturers validate their products through rigorous certification and testing processes to meet both regional and international safety benchmarks. This includes environmental tests for vibration, temperature, and ingress protection to ensure dependable use in diverse industrial applications.

Types of Metal Body Interlocks

Electro-Mechanical Interlocks

Electro-mechanical interlocks combine physical locking with electrical feedback, enhancing safety conditions during machine operation. These are commonly used in complex systems where real-time monitoring is required through integrated control units.

Trapped Key Interlocks

Trapped key interlocks use a physical key transfer system to manage access. Keys are released or captured based on machine state, offering high integrity safety protocols especially in applications requiring sequential control and reliable machine operation.

Non-Contact Interlocks

These switches use RFID or magnetic sensing to detect door position without physical contact. Ideal for clean environments like food and beverage industries, they reduce wear and support stringent hygiene requirements while still functioning as part of physical guards and safety gates.

Overview of Leading Brands

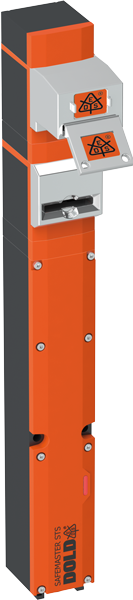

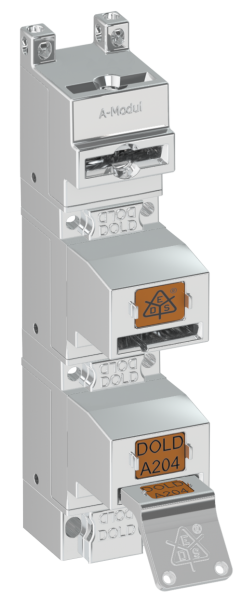

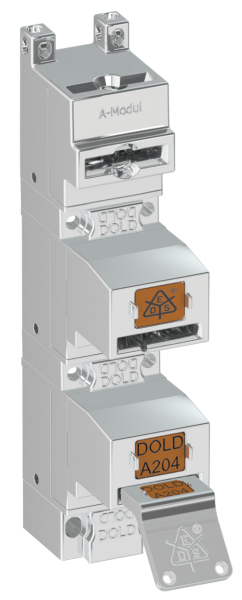

DOLD: Reliable Engineering for Machine Safety

DOLD provides a wide range of mechanical and electro-mechanical safety switches suitable for various industrial settings. Their interlocks are engineered for long-term reliability and compliance with international safety standards, supporting everything from basic machine guard systems to complex interlock networks with varied connection types.

Euchner: Precision Safety Solutions

Euchner specialises in high-performance safety devices, including robust metal body interlocks designed for secure operation in demanding environments. Their solutions are widely adopted in applications requiring advanced diagnostics, guard locking functionality, and integration with safety protocols across a wide range of products.

Pizzato: Robust and Versatile Interlocks

Pizzato offers the FG and NG series of metal body interlocks, designed for secure operation in industrial environments. The Pizzato FG series provides mechanical interlock switches ideal for safety doors and gates, while the Pizzato NG series features solenoid-controlled interlocks with high locking force and diagnostic capabilities. Both ranges are engineered for integration into machine control systems and comply with international safety standards.

Emerging Technologies in Metal Body Interlocks

RFID Safety Switches

RFID technology is revolutionising interlock devices with contactless verification, enhancing safety protocols and reducing the potential for tampering. These switches are ideal for smart factory integrations and Industry 4.0 readiness, and can be paired with modern control units and panels.

Enabling Switch Pendants

Handheld enabling devices offer three-position functionality to allow safe maintenance or troubleshooting during machine operation. They complement fixed interlocks to provide additional safety in mobile or semi-automated systems, particularly when managing access to dangerous machinery.

Integrating Metal Body Interlocks into Safety Systems

Flexibility and Customization

Modern interlock systems offer high levels of flexibility, from simple mechanical switches to smart systems with network connectivity. This allows integration into a range of applications, ensuring compatibility with specific industrial requirements and existing safety guards, safety doors, or machine control infrastructure.

Enhancing Safety and Efficiency

Integrating interlocks into broader safety systems not only prevents unsafe access but also streamlines workflows. With application library support and expert insights from vendors like Venus Automation, businesses can ensure consistent upgrades aligned with industry updates and safety goals while meeting the needs of harsh industrial environments and ensuring reliable operation under normal conditions.