12

Safety Relays: The Unsung Heroes of Industrial Safety

A Brief Overview of Safety Relays:

In the hustle and bustle of industrial workplaces, ensuring the safety of employees is paramount. Accidents can lead to serious injuries, fatalities, and significant downtime. Enter safety relays—specialized devices designed to keep machinery operating safely, creating a secure environment for workers.

Safety relays are the unsung heroes of industrial safety, ensuring that machinery operates within safe limits and immediately stopping dangerous motion when hazards arise. Designed to monitor safety inputs such as Emergency Stops, light curtains, and two-hand control stations, Industrial Safety Relays play a crucial role in preventing accidents and protecting workers from harm.

For applications requiring extended safety functions, Relay Expansion Modules allow for scalable safety solutions, seamlessly integrating with existing control systems. Specialized Emergency Stop Relays and Safety Switch Relays ensure rapid response times, immediately cutting power to hazardous machinery in critical situations.

Advanced safety systems also rely on Time Delay Relays, which introduce controlled shutdown sequences to prevent sudden stops that could damage equipment or pose risks to operators. In environments with moving machinery, Speed Monitoring Relays enhance safety by detecting irregular motor speeds and preventing dangerous overspeed conditions.

From Two-Hand Control Relays for high-risk tasks to Light Curtain Relays for automated workspaces, safety relays provide essential protection, reinforcing the importance of well-integrated industrial safety systems.

What are Safety Relays?

Safety relays are electromechanical devices that monitor and manage safety-critical inputs and outputs, such as emergency stop buttons and safety sensors. When hazardous conditions are detected, these relays ensure safe responses like stopping machinery. They are essential in various industries including manufacturing, automotive, packaging, and pharmaceuticals.

Types of Safety Relays:

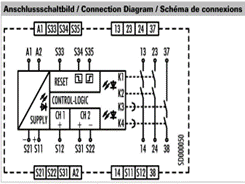

DUAL CHANNEL SAFETY RELAYS

These safety relays monitor two independent input signals, ensuring redundancy. Both channels must operate correctly for the output to switch, enhancing reliability in safety-critical applications.

TIME DELAYED SAFETY RELAYS

Featuring adjustable delays, these relays allow for a controlled sequence of operations before activating or deactivating outputs. This is useful when an immediate shutdown could cause damage or additional hazards.

FORCE GUIDED SAFETY RELAYS

Designed to ensure all contacts in the safety relay switch simultaneously, preventing contact welding or sticking, and enhancing reliability in critical applications.

EMERGENCY STOP SAFETY RELAYS

Specifically for emergency stop applications, these relays ensure immediate and reliable shutdown of machinery when an emergency stop button is pressed.

GUARD MONITORING SAFETY RELAYS

These safety relays monitor safety devices like interlock switches or safety gates, ensuring machinery cannot operate when guards are open or bypassed.

LIGHT CURTAIN SAFETY RELAYS

Interfacing with safety light curtains, these safety relays detect the presence of objects or personnel in hazardous areas, ensuring machinery stops or slows down when the light curtain is interrupted.

Time Delay Relays

In some cases, an immediate shutdown of machinery could cause damage or create additional hazards. A time delay allows for a controlled and safe shutdown sequence, preventing mechanical damage or product spoilage. Wieland’s SNV 4063KL-A features advanced time delay capabilities with adjustable delays from 0.15 to 3 seconds or 1.5 to 30 seconds, providing the flexibility to customize response times to your specific needs. This ensures your safety measures are precisely tailored to your operations.

How do safety relays work?

Safety relays operate by monitoring inputs from safety devices and evaluating these signals to ensure safe operating conditions. Here’s a breakdown of their functionality:

Continuously monitor signals from safety devices such as emergency stop buttons, guard doors, and light curtains.

Assess input signals to determine if operating conditions are safe.

Process input signals using internal logic circuitry to decide if the equipment can operate safely.

If conditions are safe, the relay energizes the output circuitry. If unsafe conditions are detected, it de-energizes the output circuity to stop the machinery.

Safety relays incorporate several advanced features to enhance their effectiveness and reliability. Many safety relays include redundant internal circuits and perform periodic self-checks to ensure proper operation and maintain reliability. They are designed to respond within milliseconds, which helps minimize risks during emergencies. Additionally, advanced relays offer diagnostic features that monitor the status and health of the relay and connected safety devices, aiding in maintenance and troubleshooting. These features collectively ensure that safety relays perform their critical functions reliably and efficiently in industrial environments.

Practical Applications:

Safety relays are used in a variety of scenarios to ensure industrial safety. They provide an immediate shutdown of machinery during emergencies through emergency stop functions. For guard monitoring, safety relays ensure that guards or barriers are in place before any operation can proceed. Light curtain monitoring involves detecting personnel or objects in hazardous areas to prevent accidents. Additionally, two-hand control requires the simultaneous operation of two buttons to initiate potentially hazardous actions, ensuring both hands are away from danger and enhancing overall safety.

Time – Delayed Safety Relays: In some situations, an immediate shutdown might cause damage or additional hazards. Time-delayed safety relays like Weiland’s SNV 4063KL-A provide customizable delays from 0.15 to 30 seconds, ensuring a controlled and safe shutdown sequence that prevents mechanical damage or product spoilage.

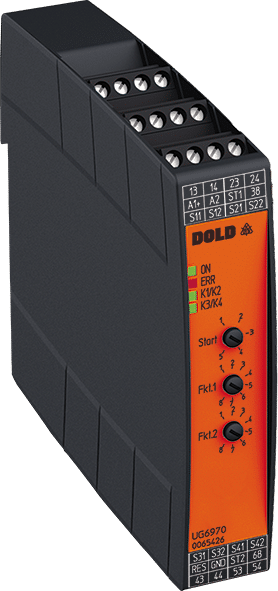

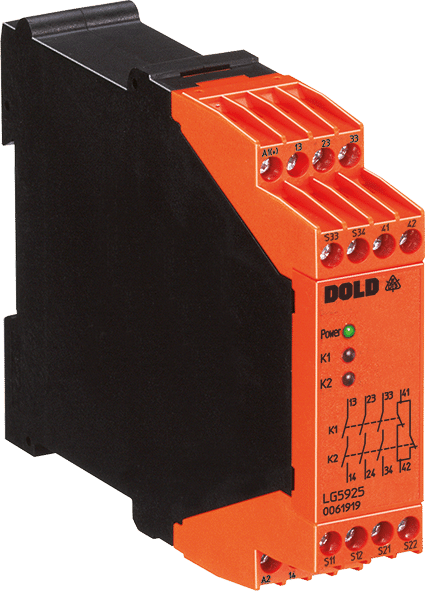

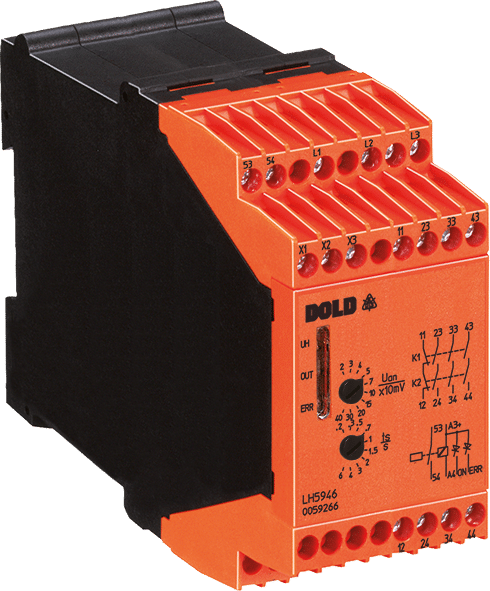

Cutting-Edge Solutions: The DOLD LH 5946 standstill speed monitor is a prime example of innovation in safety relays. It operates without requiring encoder sensors or proximity switches, detecting the standstill of electric motors by measuring the induced EMF. When the EMF approaches zero, it indicates a standstill state and activates the output relay, ensuring safe conditions.

Conclusion

Safety relays are built to withstand industrial environments, providing reliable performance over extended periods. They are easy to install, integrate seamlessly with various safety devices, and comply with international safety standards such as ISO 13849 and IEC 62061. Regular maintenance is essential to keep safety relays functioning effectively. Manufacturers provide guidelines for testing, inspection, and replacement intervals to maintain their reliability and safety.

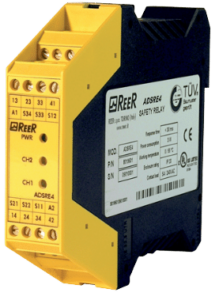

At Venus Automations, we stock a range of safety relays from top brands like Reer, Weiland, and Dold, ensuring you have access to reliable safety solutions for your industrial needs. Whether it’s emergency stop applications, guard monitoring, or integrating light curtains, safety relays are the unsung heroes that keep our workplaces safe.

Beyond Relays: A Complete Framework for Safety Monitoring and Output

While safety relays play a pivotal role in managing machine shutdowns and signal evaluation, they are just one element of a much broader safety architecture. The safety monitoring and output range at Venus Automation provides tailored solutions to meet the needs of diverse machines and projects.

A key component in modern safety systems is the safety PLC. These programmable devices allow custom safety logic, with flexible input/output terminal assignments. Venus Automation offers a variety of models, including the MOSAIC PLC from Reer, Samos PLC from Wieland, and GEMNIS PLC from Pizzato—each delivering advanced and reliable safety functionality.

Where complex programmability is unnecessary, alternative options such as the safety relay range are available. This includes standalone relays, time-delay relay, speed-monitoring relay, standstill monitoring and timer, PCB relay, relay expansion modules, and control relays like the emergency stop relay, safety edge relay, light curtains relay, and two-hand control relay. These options provide effective and application-specific safety responses.

Essential manual inputs such as the emergency stop remain integral to any safety architecture, despite lacking an automatic safety input. Venus Automation supplies complete solutions including emergency stop accessories, pushbuttons, two-hand stops, and specialized devices like the rope pull emergency stop. For modern installations, wireless safety systems, including wireless emergency stop units, remote controls and accessories, are also available.

Critical integration elements such as contact blocks are supplied to ensure seamless circuit connections. Additional safety monitoring components include the safety encoder, which monitors motor speed, and interlock devices such as tongue solenoid interlock switch and electro-magnetic switches. For more complex safety guarding, multifunctional gatebox units provide a consolidated interface, easily mounted on protective enclosures like concertina guards.

Access restriction and control can also be achieved through electronic key systems, ensuring machinery operates only under authorized conditions. Finally, for output-side protection, safety contactors and pneumatic safety valve solutions are available to ensure reliable machine stoppage when hazardous conditions are detected.

Click to view our products