Safety edges, mats, and bumpers are essential protective devices used in industrial environments to detect contact, pressure, or presence in hazardous zones. These devices provide…

Safety edges, mats, and bumpers are essential protective devices used in industrial environments to detect contact, pressure, or presence in hazardous zones. These devices provide an additional layer of safety by detecting potential collisions, entrapments, or unauthorized presence and triggering an immediate stop of machinery or equipment to prevent injuries. Safety edges, mats, and bumpers are commonly used in automated systems, machinery with moving parts, and access control areas where physical contact may occur.

Key Features

- Responsive Detection: Quickly responds to physical pressure, contact, or presence, activating safety mechanisms.

- Durable Construction: Built with resilient materials to withstand industrial conditions, including impacts, dust, moisture, and temperature variations.

- Versatile Integration: Easily integrates with safety controllers and relays to provide seamless system functionality.

- Customizable Sizes and Shapes: Available in various lengths, shapes, and sizes to fit different applications and machinery.

- Fail-Safe Design: Remains effective even during power loss or faults, ensuring continuous protection.

Types of Safety Devices

-

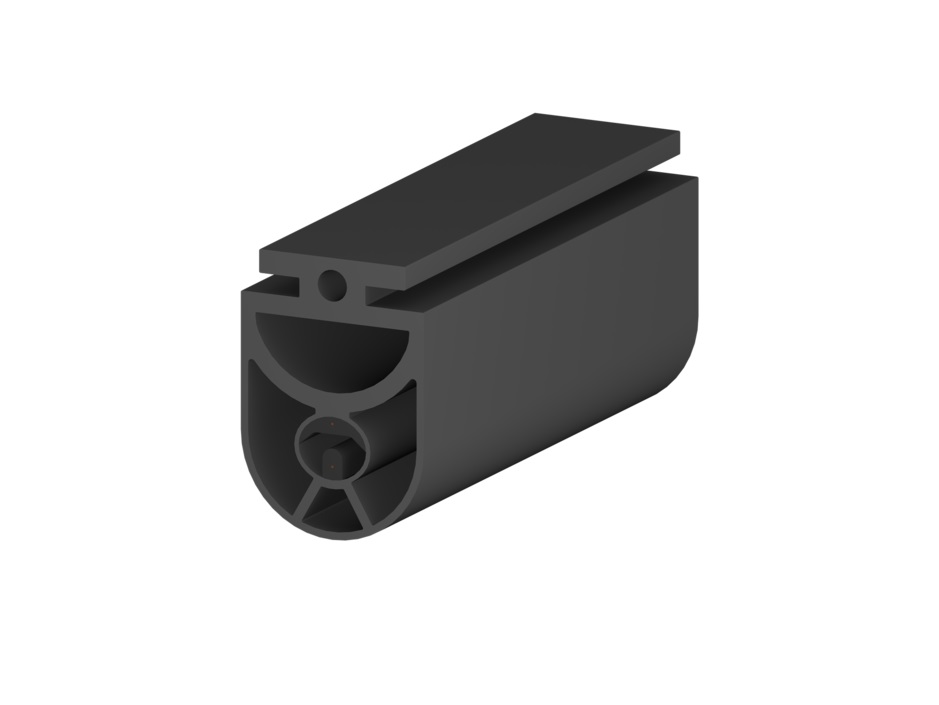

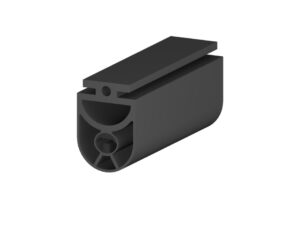

Safety Edges:

- Flexible, pressure-sensitive strips mounted on the edges of moving machinery or doors.

- Designed to detect contact and stop movement to prevent entrapment or crushing injuries.

-

Safety Mats:

- Pressure-sensitive floor mats that detect the presence of personnel in hazardous areas.

- Trigger a machine stop when weight is applied to the mat, ensuring perimeter and zone protection.

-

Safety Bumpers:

- Cushioned, impact-resistant pads installed on moving parts or vehicles to absorb shocks and detect impacts.

- Commonly used on automated guided vehicles (AGVs) and robotic arms to prevent collisions and reduce damage.

Typical Applications

- Guarding moving doors and gates in industrial and commercial settings.

- Protecting operator access points around machinery and robotic cells.

- Perimeter protection for conveyor belts and automated workstations.

- Collision protection for mobile machinery, such as AGVs and forklifts.

Broader Integration with Safety & Automation Systems

In modern industrial environments, safety edges, mats or bumpers are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Benefits of Safety Edges, Mats, and Bumpers

- Enhanced Operator Safety: Prevents collisions, entrapments, and unauthorized access to hazardous areas.

- Quick Response Time: Activates shutdown mechanisms immediately upon contact or detection.

- Flexibility and Customization: Easily adapted to various machinery types and industrial layouts.

- Low Maintenance: Durable designs require minimal maintenance for long-term use.

- Regulatory Compliance: Ensures compliance with safety standards such as ISO 13856 for pressure-sensitive protective devices.

Safety edges, mats, and bumpers are indispensable in modern industrial safety systems, providing reliable protection in dynamic environments where personnel and machinery interact. Their versatility and robust performance make them crucial for preventing accidents and maintaining safe working conditions.