22

Guardians of the Machine: How samosPRO Keeps Your Factory Safe

Weiland Samos PRO PLC

The Core of Safety systems

Safety systems in industrial environments are essential for protecting workers, machinery, and the environment from hazards. These systems typically include safety controllers, relays, sensors, switches, and actuators that monitor and control safety functions like emergency stops, interlock, monitoring, and speed control. They ensure compliance with safety standards, enabling quick responses to unsafe conditions through communication and diagnostic interfaces. Commonly used in industries like manufacturing and automotive, these systems are integrated into broader automation frameworks to maintain safety and operational efficiency.

Ensuring industrial safety requires intelligent automation solutions that provide seamless control, monitoring, and protection across manufacturing environments. The Wieland SAMOS system is designed to meet these demands, offering a highly flexible and scalable safety solution. As a leading Modular Safety Controller, it ensures that industrial operations adhere to the highest safety standards while maintaining efficiency.

At the heart of this system is the samos® PRO, a compact yet powerful Compact Safety Controller engineered to handle complex safety applications with ease. Whether integrated with existing automation infrastructure or deployed as a standalone system, the samos® PRO enhances risk mitigation by enabling real-time safety monitoring and rapid response mechanisms.

For industries seeking advanced safety automation, Safety PLCs like the samos® PRO bridge the gap between compliance and performance. This Programmable Safety Controller is designed to simplify safety logic implementation while offering extensive customization through intuitive programming tools. With the ability to manage multiple safety functions across factory floors, the samos® PRO is a game-changer in industrial safety automation.

The samos® PRO is programmed using the intuitive and license-free samos® PLAN 6 software, which includes features for automatic hardware configuration, integrated simulation, and comprehensive function block libraries certified by TÜV. This makes it ideal for ensuring functional safety in various industrial applications

Operations of the Samos controller:

1. Input Monitoring

The controller continuously monitors inputs from safety devices like emergency stops, light curtains, door switches, and sensors, detecting changes in status such as emergency activations or obstructions.

2. Logic Processing

Safety logic is configured using the samos® PLAN 6 software, allowing for the creation of safety functions and sequences with pre-certified function blocks. The logic processes input signals to determine the appropriate safety responses.

3. Output Control

The controller activates or deactivates safety outputs based on processed logic, controlling actuators, motors, and other machinery to ensure safe operation. High-power outputs can directly manage safety devices without additional relays.

4. Communication and Diagnostics

The controller uses communication gateways (e.g., PROFINET IO, EtherNet/IP, Modbus TCP) to connect with other systems, providing remote access to diagnostic information for monitoring and troubleshooting. On-site diagnostics are aided by LEDs displaying the status of all inputs and outputs.

5. Safety Assurance

The system continuously checks for faults, triggering safety responses when issues are detected. It allows simulation of sensor inputs for testing, and real-time validation with oscilloscope functions helps monitor performance and detect irregularities.

The controller continuously monitors inputs from safety devices like emergency stops, light curtains, door switches, and sensors, detecting changes in status such as emergency activations or obstructions.

Safety logic is configured using the samos® PLAN 6 software, allowing for the creation of safety functions and sequences with pre-certified function blocks. The logic processes input signals to determine the appropriate safety responses.

The controller activates or deactivates safety outputs based on processed logic, controlling actuators, motors, and other machinery to ensure safe operation. High-power outputs can directly manage safety devices without additional relays.

The controller uses communication gateways (e.g., PROFINET IO, EtherNet/IP, Modbus TCP) to connect with other systems, providing remote access to diagnostic information for monitoring and troubleshooting. On-site diagnostics are aided by LEDs displaying the status of all inputs and outputs.

The system continuously checks for faults, triggering safety responses when issues are detected. It allows simulation of sensor inputs for testing, and real-time validation with oscilloscope functions helps monitor performance and detect irregularities.

KEY features ABOUT the samos controller:

Samos® PLAN 6 Software: Intuitive operation through automatic hardware configuration, error-free commissioning with integrated simulation, and logic analysis.

Comprehensive Library: Includes TÜV-certified function blocks for various applications like muting, press, analog, and combustion libraries.

Flexible Screens: Comfortable machine setup, flexible window arrangements, and customizable layouts for laptops, PCs, and tablets.

Expandable I/O: Basic module includes 20 inputs and 4 outputs, expandable up to 116 safe inputs and 52 outputs with additional modules.

Communication Gateways: Integrated communication options include PROFINET IO, EtherNet/IP, Modbus TCP, and can be extended with PROFIBUS DP, CANopen, and EtherCAT modules.

Forcing Function: Allows simulation of missing sensor hardware, minimizing errors during shift changes and enabling fast troubleshooting.

Online Recording: Includes oscilloscope function for real-time validation and long-term recording for troubleshooting.

Remote Diagnostics: Global remote diagnostics and access via integrated Ethernet, VPN router, LAN, WLAN, or mobile radio.

Advanced Security: Protection against manipulation and unauthorized access, ensuring project integrity and security against hacker attacks.

Temperature Range: Operates in extreme conditions from -25°C to +65°C.

High Switching Power: 4A switching power per output, reducing the need for additional relays.

Standards Compliance: Meets EN 61508, EN 60204, EN 62061, EN ISO 13849-1, EN 81-20/50, EN 692, EN 693, EN/IEC 61511, EN 50156-1 standards, and is TÜV and cULus approved.

One-Click Report Generation: Simplified project documentation with one-click report generation, including project info, CRC, and safety values (SIL, Kat, PL, PFHd).

Samos® PLAN 6 Software: Intuitive operation through automatic hardware configuration, error-free commissioning with integrated simulation, and logic analysis.

Comprehensive Library: Includes TÜV-certified function blocks for various applications like muting, press, analog, and combustion libraries.

Flexible Screens: Comfortable machine setup, flexible window arrangements, and customizable layouts for laptops, PCs, and tablets.

Expandable I/O: Basic module includes 20 inputs and 4 outputs, expandable up to 116 safe inputs and 52 outputs with additional modules.

Communication Gateways: Integrated communication options include PROFINET IO, EtherNet/IP, Modbus TCP, and can be extended with PROFIBUS DP, CANopen, and EtherCAT modules.

Forcing Function: Allows simulation of missing sensor hardware, minimizing errors during shift changes and enabling fast troubleshooting.

Online Recording: Includes oscilloscope function for real-time validation and long-term recording for troubleshooting.

Remote Diagnostics: Global remote diagnostics and access via integrated Ethernet, VPN router, LAN, WLAN, or mobile radio.

Advanced Security: Protection against manipulation and unauthorized access, ensuring project integrity and security against hacker attacks.

Temperature Range: Operates in extreme conditions from -25°C to +65°C.

High Switching Power: 4A switching power per output, reducing the need for additional relays.

Standards Compliance: Meets EN 61508, EN 60204, EN 62061, EN ISO 13849-1, EN 81-20/50, EN 692, EN 693, EN/IEC 61511, EN 50156-1 standards, and is TÜV and cULus approved.

One-Click Report Generation: Simplified project documentation with one-click report generation, including project info, CRC, and safety values (SIL, Kat, PL, PFHd).

Samos Pro compact controllers:

- The system features a main CPU for managing safety functions, 16 safe inputs, 4 configurable input/outputs, and 4 dedicated outputs. It supports programming and diagnostics via Ethernet and USB. The I/O is expandable up to 112 inputs and 56 outputs, and the system complies with international safety standards.

The enhanced model includes all Basic features, with an additional Ethernet port for advanced diagnostics and monitoring. It supports analog inputs for applications like press monitoring, offers extensive diagnostics, and maintains the same I/O expandability. Programming and monitoring are enhanced via Ethernet connectivity.

- The system features a main CPU for managing safety functions, 16 safe inputs, 4 configurable input/outputs, and 4 dedicated outputs. It supports programming and diagnostics via Ethernet and USB. The I/O is expandable up to 112 inputs and 56 outputs, and the system complies with international safety standards.

The enhanced model includes all Basic features, with an additional Ethernet port for advanced diagnostics and monitoring. It supports analog inputs for applications like press monitoring, offers extensive diagnostics, and maintains the same I/O expandability. Programming and monitoring are enhanced via Ethernet connectivity.

Common features in the Samos Pro compact series:

Emergency Stop Monitoring

- Both controllers monitor emergency stop buttons and circuits, ensuring that machinery can be quickly halted in case of an emergency. This is crucial for preventing accidents and injuries.

Safety Gate Monitoring

- They monitor safety gates and doors, ensuring that machinery cannot operate unless safety gates are securely closed. This protects operators from accessing dangerous areas during machine operation.

Light Curtain Integration

- The controllers are used with safety light curtains to detect the presence of operators or objects in hazardous zones. If the light curtain beam is interrupted, the controller can initiate a safe stop of the machinery.

Two-Hand Control Monitoring

- Both products can monitor two-hand control systems, which require an operator to use both hands to initiate a machine cycle, ensuring that hands are clear of the danger zone during operation.

Muting Functions

- They support muting functions, temporarily bypassing safety devices under controlled conditions, such as allowing materials to pass through safety light curtains without stopping the machine.

Speed and Standstill Monitoring

- The controllers can monitor the speed and standstill of machines, ensuring they operate within safe limits. They can stop the machine if unsafe speeds are detected or if the machine does not come to a complete stop when required.

Analog Signal Monitoring

- Particularly with the samosPRO Compact Plus, analog inputs can be monitored for applications like temperature, pressure, or other critical process variables. This ensures that machinery operates within safe parameters.

Press Safety Applications

- In press and forming operations, the controllers manage safety functions such as monitoring the safe position of press elements, ensuring that operators are not exposed to moving parts.

Integration with Other Safety Systems

- Both controllers can integrate with other safety devices and systems, such as safety relays, to provide comprehensive safety management across complex machinery setups.

Communication and Diagnostics

- They provide detailed diagnostic information and communication capabilities, enabling quick identification and resolution of safety issues, thus maintaining a safe operating environment.

- Both controllers monitor emergency stop buttons and circuits, ensuring that machinery can be quickly halted in case of an emergency. This is crucial for preventing accidents and injuries.

- They monitor safety gates and doors, ensuring that machinery cannot operate unless safety gates are securely closed. This protects operators from accessing dangerous areas during machine operation.

- The controllers are used with safety light curtains to detect the presence of operators or objects in hazardous zones. If the light curtain beam is interrupted, the controller can initiate a safe stop of the machinery.

- Both products can monitor two-hand control systems, which require an operator to use both hands to initiate a machine cycle, ensuring that hands are clear of the danger zone during operation.

- They support muting functions, temporarily bypassing safety devices under controlled conditions, such as allowing materials to pass through safety light curtains without stopping the machine.

- The controllers can monitor the speed and standstill of machines, ensuring they operate within safe limits. They can stop the machine if unsafe speeds are detected or if the machine does not come to a complete stop when required.

- Particularly with the samosPRO Compact Plus, analog inputs can be monitored for applications like temperature, pressure, or other critical process variables. This ensures that machinery operates within safe parameters.

- In press and forming operations, the controllers manage safety functions such as monitoring the safe position of press elements, ensuring that operators are not exposed to moving parts.

- Both controllers can integrate with other safety devices and systems, such as safety relays, to provide comprehensive safety management across complex machinery setups.

- They provide detailed diagnostic information and communication capabilities, enabling quick identification and resolution of safety issues, thus maintaining a safe operating environment.

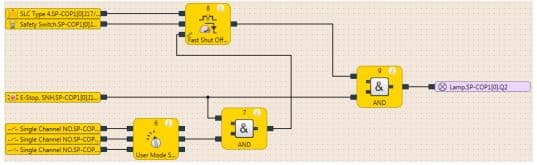

Samos PRo wiring and coding examples:

The samosPRO Compact system’s wiring involves connecting safety devices like emergency stops and light curtains to the controller’s inputs, while outputs manage actuators and machinery. The system can be expanded with additional modules for more inputs and outputs. Coding is done through the samos® PLAN 6 software, where safety logic is configured using drag-and-drop function blocks. The software allows for the creation of safety sequences, simulation, and testing, simplifying the integration and ensuring compliance with safety standards.

From Control to Response: Expanding into Safety Monitoring & Output Solutions

The SAMOS® PRO demonstrates how advanced safety PLCs form the core of responsive, intelligent safety systems—but safety doesn’t stop at the controller. The safety monitoring and output range at Venus Automation provides tailored solutions to meet the needs of diverse machines and projects.

A key component in modern safety systems is the safety PLC. These programmable devices allow custom safety logic, with flexible input/output terminal assignments. Venus Automation offers a variety of models, including the MOSAIC PLC from Reer, Samos PLC from Wieland, and GEMNIS PLC from Pizzato—each delivering advanced and reliable safety functionality.

Where complex programmability is unnecessary, alternative options such as the safety relay range are available. This includes standalone relays, time-delay relay, speed-monitoring relay, standstill monitoring and timer, PCB relay, relay expansion modules, and control relays like the emergency stop relay, safety edge relay, light curtains relay, and two-hand control relay. These options provide effective and application-specific safety responses.

Essential manual inputs such as the emergency stop remain integral to any safety architecture, despite lacking an automatic safety input. Venus Automation supplies complete solutions including emergency stop accessories, pushbuttons, two-hand stops, and specialized devices like the rope pull emergency stop. For modern installations, wireless safety systems, including wireless emergency stop units, remote controls and accessories, are also available.

Critical integration elements such as contact blocks are supplied to ensure seamless circuit connections. Additional safety monitoring components include the safety encoder, which monitors motor speed, and interlock devices such as tongue solenoid interlock switch and electro-magnetic switches. For more complex safety guarding, multifunctional gatebox units provide a consolidated interface, easily mounted on protective enclosures like concertina guards.

Access restriction and control can also be achieved through electronic key systems, ensuring machinery operates only under authorized conditions. Finally, for output-side protection, safety contactors and pneumatic safety valve solutions are available to ensure reliable machine stoppage when hazardous conditions are detected.

Click to view our product Range