The Importance of Safety Contactors Safety vs. General-Purpose Contactors Safety contactors are purpose-built to meet the stringent demands of industrial safety systems. Unlike general-purpose contactors,…

The Importance of Safety Contactors

Safety vs. General-Purpose Contactors

Safety contactors are purpose-built to meet the stringent demands of industrial safety systems. Unlike general-purpose contactors, which simply control electrical loads, safety contactors are designed to ensure safe disconnection in case of a fault or emergency. They often feature mechanically linked auxiliary contacts and positively driven operation, making them essential in systems that require safety circuit redundancy and fail-safe operation.

Role in Machinery Safety

In industrial environments, safety contactors play a crucial role in machine guarding, emergency shutdown, and automated fault isolation. Whether it’s stopping hazardous motion or isolating power during maintenance, a safety contactor acts as a reliable safety interface in machinery risk reduction strategies. This functionality makes them indispensable in automated manufacturing lines and robotic systems.

Emergency Power Disconnection

When connected with safety systems such as emergency stop buttons or light curtains, safety contactors provide immediate power isolation to dangerous equipment. This is critical in preventing injuries during unexpected operational failures. The inclusion of a Hokuyo safety laser scanner, for instance, adds advanced detection capabilities that, when coupled with a safety contactor, forms a robust emergency disconnection system.

Broader integration with Safety & Automation Systems

In modern industrial environments, safety contactors are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs and safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Key Features of Safety Contactors

Performance and Reliability

Designed for industrial applications, safety contactors must operate under demanding conditions. Features like high switching capacity, long electrical life, and resistance to environmental stress ensure dependable performance. Models are available with 3-pole and 4-pole configurations, and support standard voltages including 24V DC and 110V AC to suit various safety control systems.

Safety Certifications and Standards

Compliance with international safety standards such as IEC 60947-4-1 and ISO 13849 is essential. Certified safety contactors include safety-rated auxiliary contacts, redundant circuits, and support integration with dual-channel safety monitoring relays. These certifications guarantee suitability for Category 4 and Performance Level e safety circuits.

Selecting the Right Safety Contactor

Importance of Correct Model Selection

Choosing the appropriate safety contactor depends on several factors: load current, control voltage, application type, and the need for auxiliary contact blocks or overload protection. Users should also consider if the contactor is to be used in a machine control center (MCC) or a standalone safety application.

Notable Safety Contactor Models

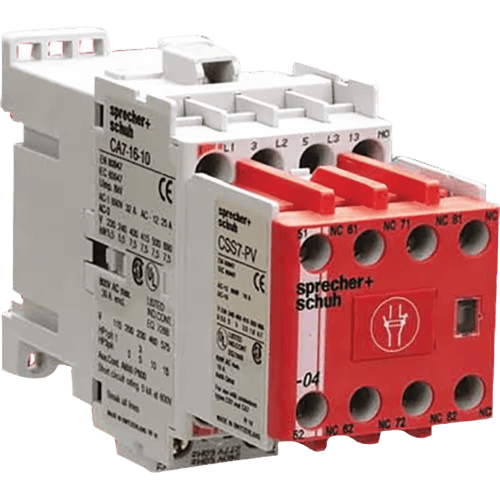

Sprecher + Schuh Safety Contactors

Sprecher + Schuh models are recognized for integrating seamlessly with electrical and motor control systems. With compact dimensions, they offer features like mechanical interlocks, auxiliary contacts, and compatibility with overload relays, ideal for use in safety circuits with frequent stop-start cycles.

Safety Contactor Applications

Usage in Machine Control Centers (MCCs)

Safety contactors are standard components in machine control centers, enabling centralized and safe power distribution. Their ability to disconnect multiple motors or drives with a single control signal streamlines system safety architecture in complex installations.

Advanced Design Features and Installation Flexibility

Modern safety contactors offer a comprehensive product range designed to meet the diverse needs of industrial safety systems. These devices handle electrical loads, including high-current and high-power loads, ensuring safe and efficient switching in demanding applications.

A key safety innovation is the use of mirror contacts and integrated mirror contacts, which ensure reliable operation of emergency stop circuits. These contacts provide critical feedback capabilities to the control system, allowing for contacts for feedback circuit monitoring and real-time contactor status verification. This is essential when configuring emergency stops and emergency stop button integrations into control panel design.

Most units support various coil options and customisable options, offering flexibility in installation options for electrical panels of any size or complexity. Engineers can choose from multiple control supply voltage levels, ensuring compatibility across different control voltage branches. High insulation voltage ratings and certified protection ratings further guarantee safety under continuous operation.

To aid installation, features such as closed terminal designs and clearly marked control terminals simplify wiring. Many models follow a color code standard, often using an eye-catching yellow color for safety components, improving visibility and reducing wiring errors during panel assembly.

For those seeking efficient energy usage, advanced contactors may include an energy auxiliary function that monitors consumption and helps reduce energy costs. Combined with a comprehensive range of options and accessories, these devices are ideal for streamlined integration and enhanced safety.

Whether you’re upgrading existing systems or designing a new control panel layout, referencing an industry tech tip or control panel design guide ensures you leverage the full capability of today’s safety contactor technology.