Emergency stops (often referred to as emergency stop devices or E-stop buttons) are a fundamental safety mechanism used across industrial environments to halt machinery immediately…

Emergency stops (often referred to as emergency stop devices or E-stop buttons) are a fundamental safety mechanism used across industrial environments to halt machinery immediately in the event of an emergency situation. These devices play a crucial role in mitigating risks associated with hazardous motion, equipment failure, or accidental entrapment during a production process.

By initiating a fail-safe operation, E-stops help prevent injury to personnel and reduce the potential for damage to equipment. They are a legal and functional requirement in most industrial equipment setups, particularly in areas where workers are exposed to hazardous situations.

Key Features of Emergency Stop Devices

Reliable Actuation Mechanisms

A core feature of all emergency stop switches is their ability to deliver consistent and fail-safe performance. Most rely on spring pressure to maintain engagement until a manual action resets the device. High-quality E-stops offer one-of-a-kind safe break action design to ensure circuit interruption even in cases of contact block failure or improper installation.

Advanced models, including conventional E-stop switches from top brands, also integrate redundant additional contact features to maintain system integrity and satisfy machine safety standards.

Strategic Placement for Accessibility

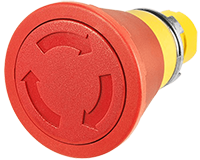

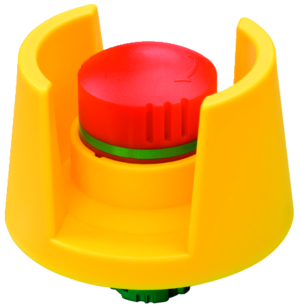

E-stops must be strategically installed in control panels or on machines where an accessible button can be reached quickly during a foreseeable emergency. To be effective, they must be clearly visible—usually with a yellow background and prominent red emergency button—and operable with a deliberate action.

Design guidelines often require E-stops to be mounted on the front face of enclosures or panel mount installations, making them accessible even in harsh environments or when wearing PPE.

Resetting Protocols Post-Activation

Once triggered, the emergency stop function must remain latched until a deliberate reset is performed. This helps maintain a clear distinction between normal operation and post-incident evaluation. Resetting mechanisms may vary—ranging from key-release push types to manual rotation resets—but all must comply with industry safety codes and preserve human safety.

In advanced systems, resetting an E-stop may require confirmation via interlinked interlock devices, especially when integrated into more complex industrial machines.

Broader Integration with Safety & Automation Systems

While emergency stop components are critical within safe industrial systems, these are only one part of an integrated safety system. These devices will work in tandem with various critical components such as safety PLCs, safety contactors, two hand stations or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Types of Emergency Stops

Push Buttons

The most common E-stop type is the emergency stop button—a large, red, mushroom-head switch designed for fast identification and ease of use. Typically mounted on control panels or machine surfaces, these buttons provide instant shutdown through a spring-loaded mechanism and often include options for 30mm XN E-stops, illuminated rings, or anti-tamper designs.

They are used across a wide range of applications and are a default safety component on most factory and automation systems.

Pull Cords

Pull cord E-stops are used for larger equipment or conveyor systems where multiple personnel may need access to an emergency shutoff. A Cable Pull Switch extends a cord across the length of the machine, and pulling the cord activates the emergency stop function immediately.

Ideal for hazardous motion zones or hygienic environments, pull cords are a reliable option for maintaining coverage over large machines without needing multiple push buttons.

Applications Across Industries

Robotics Systems

In robotics systems, the risk of unexpected motion, pinching, or collision is significant. Emergency stop devices are strategically integrated at operator stations and on the robot itself to immediately halt motion in case of hazardous situations. These E-stops help prevent damage to equipment and protect against hazardous motion, especially during maintenance or teaching modes.

Advanced robots often feature E-stops with illuminated feedback and additional contact points, ensuring feedback loops are maintained within broader safety PLC networks.

Manufacturing Environments

E-stops are a standard requirement in modern manufacturing environments, especially where fast-moving machinery or human interaction with industrial machines is frequent. Whether mounted on control panels, conveyor lines, or heavy equipment, these emergency stop switches provide workers a simple yet effective interface to respond in real-time to emergency situations.

Manufacturers often choose from a wide variety of designs—from push buttons to pull cords—tailored to specific production layouts and safety zones.

Installation Guidelines

Panel Mounts

Panel mount installations are among the most common E-stop configurations. These are embedded directly into operator stations, control enclosures, or junction boxes, offering centralized control within reach of technicians. The yellow background and red emergency stop button make them immediately recognizable.

Panel-mounted E-stops are ideal for permanent machinery and are usually equipped with robust contact blocks for long-term reliability.

Surface Mounts

Where flexibility is essential, surface mount emergency stop devices provide an external mounting option. These are ideal for retrofitting existing equipment or use in environments where machinery is regularly repositioned. Surface-mounted E-stops often come prewired and ready to install with manual action reset mechanisms, supporting fast deployment without panel cutouts or additional enclosure space.

Safety Standards and Regulations

Emergency stop systems must comply with strict global standards to ensure fail-safe operation and protect human safety. Common standards include ISO 13850 (Safety of machinery – Emergency stop function), IEC 60947-5-5, and ANSI B11.0 for North America.

These standards define essential criteria such as:

- Latching behavior after activation

- Required manual reset

- Resistance to improper installation

- Color-coding (e.g., yellow background and red button)

- Suitability for harsh environments

Regulatory adherence ensures that your E-stops are not only functionally effective but legally compliant and ready for inspection across jurisdictions.

Maintenance and Consistent Operation

Maintaining E-stop functionality is vital for safety assurance. Routine testing should verify that:

- The contact blocks engage reliably

- The emergency stop button resets correctly

- Wiring is intact and not compromised by vibration or environmental exposure

- Devices respond under standard and foreseeable emergency conditions

Replace damaged components immediately, and inspect units regularly—especially in environments with chemical hazards, high humidity, or abrasive materials—to avoid failure during critical events.