7

You Would NOT Believe This: DSP LASERS

DSP laser system Overview :

In modern industrial settings, precision and safety go hand in hand. As automation advances, so does the need for cutting-edge safety solutions that can effectively monitor and control hazardous areas. One such breakthrough technology is the DSP Laser System, a revolutionary solution designed to enhance workplace safety and operational efficiency. By utilizing advanced laser detection, these systems provide accurate, real-time monitoring of restricted zones, preventing unauthorized access and reducing the risk of accidents.

Unlike traditional safety barriers, DSP lasers offer non-intrusive, highly adaptable protection without interfering with workflow. Their ability to detect objects with pinpoint accuracy makes them ideal for safeguarding robotic workstations, automated machinery, and high-risk environments. These intelligent laser sensors can seamlessly integrate into existing safety automation systems, ensuring compliance with strict industry regulations while maximizing productivity.

As industries continue to prioritize worker safety, technologies like DSP laser systems are becoming essential components in comprehensive risk mitigation strategies. Whether in manufacturing, logistics, or high-speed production lines, the implementation of laser-based safety solutions represents a significant leap forward in industrial protection, delivering unmatched reliability and precision.

Safety in industrial workplaces is paramount, encompassing measures and technologies designed to protect workers from accidents and injuries. Key aspects include the implementation of safety protocols, use of personal protective equipment (PPE), and integration of advanced safety systems. The DSP Laser System exemplifies such safety technology, offering precise monitoring of hazardous zones around machinery.

By utilising laser beams to create a detection area, the DSP Laser System can instantly stop machinery if an intrusion is detected, preventing potential accidents. This system is particularly valuable in metalworking with press-brake machines, where it safeguards operators from injuries caused by inadvertent machine movements. Thus, DSP Laser Systems significantly enhance workplace safety by providing a reliable and immediate response to dangerous situations.

WHAT is the dsp laser system?

A DSP (Digital Signal Processing) Laser System refers to a type of laser system that incorporates digital signal processing techniques to enhance its performance and capabilities. These systems are used in various applications such as communications, medical devices, manufacturing, and scientific research.

Key overview of the DSP laser system:

Purpose and Function

The DSP Laser System is designed to improve safety in industrial settings, particularly for press-brake operations. It creates a monitored detection area that stops machine movements upon intrusion, protecting operators. The system includes features like an inhibition function for safe operations and overtravel monitoring, ensuring compliance with safety standards and preventing accidents.

Applications

The DSP Laser System enhances safety by creating a detection area between the dies of a press-brake, instantly stopping the machine’s dangerous movements if interrupted, thereby protecting operators. It includes an inhibition function that allows the stop signal to be bypassed only when the machine’s closing speed is 10 mm/s or less, preventing accidents during slow movements. Additionally, the system monitors overtravel by interfacing with position detectors, ensuring compliance with safety standards.

features

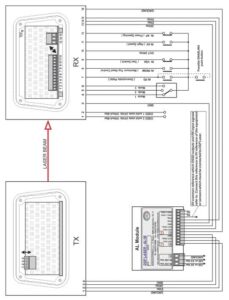

The DSP Laser System includes a transmitter and receiver powered by 24Vac or 24Vdc, with an optional DSP LASER AL module. It enhances safety by stopping machine movements if an intrusion is detected in the detection area. The system supports different operating modes for various processing needs and features automatic overtravel monitoring, fault indication via LEDs, and ON/OFF signals from OSSD outputs. It offers multiple power supply options, including modules for 24Vdc and 220Vac or 24Vac.

integration

DSP technology facilitates the integration of laser systems with other digital and automated systems, enabling advanced automation and control in industrial and scientific settings.

The DSP Laser System is designed to improve safety in industrial settings, particularly for press-brake operations. It creates a monitored detection area that stops machine movements upon intrusion, protecting operators. The system includes features like an inhibition function for safe operations and overtravel monitoring, ensuring compliance with safety standards and preventing accidents.

The DSP Laser System enhances safety by creating a detection area between the dies of a press-brake, instantly stopping the machine’s dangerous movements if interrupted, thereby protecting operators. It includes an inhibition function that allows the stop signal to be bypassed only when the machine’s closing speed is 10 mm/s or less, preventing accidents during slow movements. Additionally, the system monitors overtravel by interfacing with position detectors, ensuring compliance with safety standards.

The DSP Laser System includes a transmitter and receiver powered by 24Vac or 24Vdc, with an optional DSP LASER AL module. It enhances safety by stopping machine movements if an intrusion is detected in the detection area. The system supports different operating modes for various processing needs and features automatic overtravel monitoring, fault indication via LEDs, and ON/OFF signals from OSSD outputs. It offers multiple power supply options, including modules for 24Vdc and 220Vac or 24Vac.

DSP technology facilitates the integration of laser systems with other digital and automated systems, enabling advanced automation and control in industrial and scientific settings.

operational steps

The DSP Laser System package includes a transmitter (TX), receiver (RX), testing and positioning instruments, and an instruction manual, with optional modules such as ALdc, AL1B, and AL2B available. Proper mechanical installation is essential, with the detection area accurately positioned under the upper tool to define the safety intervention limits. Electrical connections require separate wiring for OSSD outputs to ensure redundancy and safety, with modules installed within an electrical board rated at least IP 54. After installation, the system must be adjusted using the provided instruments to correctly set the protection area and verify the OSSD outputs’ functionality.

applications and functions

The DSP LASER system creates a detection area between the dies of a press-brake. Any interruption in this area immediately stops the machine’s dangerous movements, ensuring operator safety

The system allows inhibition of the stop signal only if the machine’s closing speed is reduced to 10 mm/s or less, preventing accidents during the closing stroke of the press-brake

The control circuit can interface with position detectors to monitor overtravel, enhancing compliance with safety standards

The DSP LASER system creates a detection area between the dies of a press-brake. Any interruption in this area immediately stops the machine’s dangerous movements, ensuring operator safety

The system allows inhibition of the stop signal only if the machine’s closing speed is reduced to 10 mm/s or less, preventing accidents during the closing stroke of the press-brake

The control circuit can interface with position detectors to monitor overtravel, enhancing compliance with safety standards

The DSP Laser System provides key benefits including enhanced safety by immediately stopping machine movements upon detecting intrusions, versatile operation modes for different processing needs, and automatic monitoring features that ensure compliance with safety standards. It offers reliable performance with clear fault indicators, and flexible power supply options. Additionally, its easy integration and adjustments make it adaptable to various industrial applications, particularly in metalworking.

key benefits of the dsp laser system

Description:

DSP allows for precise control of laser parameters such as pulse width, repetition rate, and power output, leading to improved accuracy and efficiency in applications..

Description:

Digital signal processing can enhance the stability and reliability of the laser output by minimizing noise and other disturbances.

Description:

DSP Laser Systems can be programmed and reconfigured for different tasks, making them versatile for various applications.

Description:

These systems often include features such as real-time monitoring, adaptive control, and diagnostics, which help in optimizing performance and maintaining system health.

Description:

DSP technology facilitates the integration of laser systems with other digital and automated systems, enabling advanced automation and control in industrial and scientific settings.

Description:

DSP allows for precise control of laser parameters such as pulse width, repetition rate, and power output, leading to improved accuracy and efficiency in applications..

Description:

Digital signal processing can enhance the stability and reliability of the laser output by minimizing noise and other disturbances.

Description:

DSP Laser Systems can be programmed and reconfigured for different tasks, making them versatile for various applications.

Description:

These systems often include features such as real-time monitoring, adaptive control, and diagnostics, which help in optimizing performance and maintaining system health.

Description:

DSP technology facilitates the integration of laser systems with other digital and automated systems, enabling advanced automation and control in industrial and scientific settings.

offered products

Nuova’s DSP Laser System is a safety device designed to protect operators in industrial settings, particularly around press brakes. It features a transmitter and receiver that create a detection zone around the machine’s moving parts. If any object or person enters this zone, the system immediately stops the machine to prevent accidents. The DSP Laser System supports various operating modes for different applications, includes automatic monitoring for compliance with safety standards, and offers flexible installation options with multiple power supply configurations. It ensures reliable operation and enhances workplace safety by providing quick response to potential hazards.

DSP Laser wiring with AL Module

Building a Complete Input Framework: Beyond Laser Detection

While the DSP Laser System excels at guarding critical machine zones with pinpoint precision, it represents just one layer in a much broader safety input strategy.

Venus Automation offers a wide range of safety input devices to suit varied industrial applications. Detection solutions include the safety light curtain range, available for body protection, hand protection, and finger protection. Options supporting long range sensing and outdoor environments are available, along with muting light curtain models designed for automated processes. Supporting components such as photo cells, connection boxes, and muting accessories are also stocked. Additional detection options include multi beam systems and advanced laser scanner technologies.

To detect presence or motion at close range, proximity sensors are available, including non-contact switches, with magnetic, RFID, or stainless-steel technologies. Enclosures come in plastic, metal, or stainless-steel body variants for application-specific durability.

Mechanical safety detection is supported by products such as safety edge and mounting systems, contact mats, and bumpers with relevant edge accessories. These are ideal for perimeter and surface-triggered protection zones. For advanced zone control, trapped key systems and blocking devices ensure process integrity.

Manual control inputs are also critical in many safety scenarios. Venus Automation provides safety enabling switches, limit switch options, foot pedal switches, control pads, and standard control components.

Together, these input systems interface with the machine’s transmission system, ensuring rapid response to unsafe conditions. Combined with suitable outputs and logic control, they serve as the first line of defence in safeguarding personnel and equipment.

Click to view our products