Machine Guarding and Its Importance in Industrial Safety

Overview of Machine Guarding

Machine guarding is a fundamental safety measure in industrial environments, designed to protect workers from mechanical hazards, moving parts, and dangerous machine functions. At its core, machine guarding involves using a physical barrier or safety device to prevent accidental contact with hazardous components during normal operation or maintenance.

Common types of machine guards include fixed guards, adjustable guards, interlocked devices, light curtains, and awareness barriers. These are deployed based on the type of guard needed for specific equipment, ranging from milling machine guards to retractable curtains used around forging machines and industrial machinery.

The presence of effective guards ensures that machine operators can carry out tasks safely without risking exposure to hazardous motion, jagged edges, or unfinished surfaces. Guarding systems are also engineered to restrict access to danger areas, mitigating the chance of preventable injuries such as lacerations, amputations, or crushing incidents.

As part of a comprehensive machine safety program, guarding solutions support safe work practices, fulfil safety requirements, and align with ANSI/RIA-compliant machine safety protocols. More importantly, they help reduce severe workplace injuries and reinforce the safety of workers across various industries.

Types of Machine Guarding Methods

Modern industrial environments demand tailored guarding methods to suit varying equipment, processes, and operational hazards. Whether it’s protecting a machine operator from a rotating shaft or preventing access to high-risk areas during active motion, these methods are designed to ensure maximum protection and workplace safety across a wide variety of applications.

Fixed Perimeter Guarding

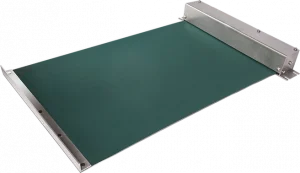

Fixed perimeter guarding is a common type of physical barrier that surrounds or encloses hazardous zones to block direct human access during machine operation. These guards are typically constructed from steel mesh panels, gates, or modular fencing systems and are ideal for dangerous machinery like robotic cells, palletizers, and large industrial machinery.

This method ensures maximum safety by clearly defining the vicinity of machinery, preventing accidental contact, and complying with comprehensive machine safety protocols. Milling machine guards, for example, use fixed guarding around moving cutters and belts to reduce mechanical hazard exposure.

Fixed guarding is highly durable, requires minimal maintenance, and is suited for applications where access during operation is unnecessary or restricted to maintenance intervals.

Safety Devices

Safety devices include technologies like light curtains, two-hand controls, interlock switches, and pressure-sensitive mats that respond dynamically to operator presence. These devices are critical in areas where a fixed guard may hinder efficiency or operator workflow.

Light curtains create an invisible protective field around hazardous zones—if interrupted, they immediately shut down the machinery. Two-hand controls require simultaneous use of both hands to start or maintain operation, minimizing the risk of accidental contact with mechanical motions.

These systems are crucial for advanced machine safety, allowing for flexibility without compromising on safety requirements. They are often integrated with standard components of control systems and contribute to maximum protection in environments where frequent maintenance or material handling is required.

Awareness Barriers

Awareness barriers—such as warning lines, barrier tape, or low-profile fencing—serve as visual or physical cues to alert personnel of nearby hazards. Though not intended to physically stop access like fixed guards, they play a key role in hazard recognition and preventable injuries.

This method is suitable for low-risk zones or in combination with administrative controls where access to danger areas must be discouraged but not physically restricted. Awareness barrier safeguards are commonly used near conveyors, tool-change zones, or unfinished surfaces that pose a tripping mechanism or minor hazard.

Their success depends heavily on employee training, clear signage, and strong procedural enforcement—making them a supporting element rather than a standalone guard.

Implementation of Machine Guarding

Successfully implementing machine guards requires more than just installing physical barriers. It demands a strategic approach that combines engineering principles, risk analysis, and adaptability to modern technologies. A well-executed implementation ensures maximum safety, reduces preventable injuries, and aligns with evolving industry trends such as Industry 5.0.

By incorporating tailored solutions—from adjustable guards to smart safety devices—businesses can improve protection, ensure compliance with safety requirements, and enhance the overall safety of workers.

Designing Effective Guarding Systems

Designing effective machine guarding systems begins with identifying the type of guard best suited to the machine’s function and operational environment. This involves evaluating:

- The machine’s moving parts and potential for hazardous motion

- Operator interaction points and access to danger areas

- Requirements for visibility, cleaning, or maintenance

An effective design ensures that guards don’t interfere with normal operation, while still acting as reliable physical barriers. For example, milling machine guards must prevent contact with rotating cutters while maintaining clear access for material placement and visual monitoring.

Design considerations also include standard components, ergonomic access, inspection windows, and compatibility with other safety controls, such as two-hand controls or interlocks.

Risk Assessment and Hazard Analysis

Prior to installation, every machine type must undergo a detailed risk assessment and hazard analysis. This process involves:

- Identifying mechanical hazards such as nip points, shear points, and jagged edges

- Evaluating equipment hazards and exposure during startup, shutdown, or emergency stops

- Analyzing potential for severe workplace injuries like amputations or crush incidents

A solid hazard analysis helps determine if fixed guarding, awareness barriers, or advanced safety devices like light curtains are the appropriate solutions. It also informs decisions about necessary administrative controls and operator training, reducing the likelihood of workplace injuries.

By basing guard selection on actual risk data, businesses achieve targeted protection that aligns with both OSHA and ISO compliance with safety requirements.

Role of Administrative Controls

While physical machine guards and safety devices are essential, administrative controls play a vital role in maintaining workplace safety. These controls provide the procedural and organizational framework to ensure that safety measures are followed consistently, especially in facilities with high interaction between personnel and industrial machinery.

Administrative controls help mitigate residual risks that remain even after mechanical safeguarding, ensuring a complete and compliant machine guarding safety program.

Establishing Roles and Responsibilities

Clearly defined roles and responsibilities are the foundation of any effective safety system. Designating accountable personnel for safety oversight, equipment monitoring, and incident reporting ensures that machine guarding policies are not just documented—but actively enforced.

Each machine operator should understand their scope of work, access limitations, and response protocols for guard-related issues. Supervisors must be responsible for verifying compliance, ensuring that physical barriers are in place, and coordinating with maintenance teams when safety systems are compromised.

This structure reduces confusion during emergencies, supports incident response, and ensures that everyone involved is aware of their contribution to maximum protection and operational integrity.

Training for Operators and Supervisors

No guarding system is effective without proper training. All personnel must receive comprehensive instruction on safe work practices, recognizing mechanical hazards, and operating within the limitations defined by machine guards.

Training should include how to use two-hand controls, how to visually inspect adjustable guards, and what to do if a guard or light curtain is bypassed or damaged. For supervisors, the focus should expand to include documentation procedures, enforcing safety requirements, and reporting issues during audits or walkthroughs.

Continual training reduces the likelihood of accidental contact, improves hazard awareness, and aligns teams with regulatory standards like OSHA and ISO.

Regular Inspections and Maintenance

Administrative control frameworks must include a schedule for regular inspections and maintenance. Over time, guards can become loose, damaged, or misaligned—especially on equipment with frequent maintenance needs or high-cycle operations.

Supervisors should use machine safety checklists to confirm the presence, condition, and functionality of guards and safety devices. Operators should be encouraged to report unusual wear or obstruction during daily checks.

Timely maintenance not only prevents exposure to hazardous motion and unfinished surfaces but also ensures continued compliance with safety requirements. Proper recordkeeping of inspections and corrective actions further strengthens accountability and demonstrates regulatory due diligence.

Broader integration with Safety & Automation Systems

In modern industrial environments, Industrial Fencing Guards are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, under voltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.