Introduction to Emergency Stop Devices Definition and Purpose A safety emergency stop is a critical control device designed to halt machinery instantly in hazardous situations.…

Introduction to Emergency Stop Devices

Definition and Purpose

A safety emergency stop is a critical control device designed to halt machinery instantly in hazardous situations. Also known as an emergency stop button, E-stop button, or emergency stop switch, it serves as a first line of defense to prevent injuries or equipment damage by immediately disconnecting power or initiating a controlled stop.

Importance in Industrial Safety

Emergency stops are required in nearly all automated industrial settings. They comply with international safety standards such as ISO 13850 and IEC 60947-5-5, ensuring consistent safety protocols across industries. In sectors like manufacturing, automation, and robotics, they are essential for protecting personnel and equipment during dangerous events or overpressure events.

Broader integration with Safety & Automation Systems

While emergency stop buttons are critical within safe industrial systems, these components are only one part of an integrated safety system. These systems may work in tandem with various critical components such as safety PLCs, safety contactors, two hand stations or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Types of Emergency Stop Devices

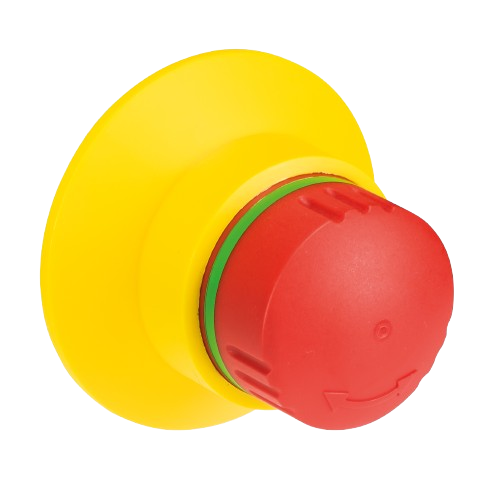

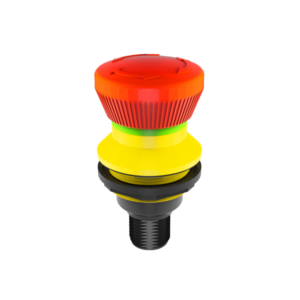

Emergency Stop Button

The emergency stop button is the most common form, typically featuring a red mushroom-shaped actuator. Designed for immediate activation, it is highly visible and intuitive, playing a vital role in machine downtime prevention.

Emergency Stop Switch

These emergency stop switches may include rotary, push-pull, or key-release mechanisms and are found in both control voltage branches and industrial network protocols.

E-Stop Button

The term E-stop button is used interchangeably with the emergency stop button but may specifically refer to versions with integrated mirror contacts, allowing feedback circuits to confirm safe activation.

Cable Pull Wire Switches

Ideal for long conveyor systems, pull cord emergency stop devices provide continuous access along hazardous zones and are suited to areas where standard buttons are impractical.

Grip Enabling Switches

These allow operators to maintain safe control during manual operations. Integrated in robotic safety systems, they add layered protection in sensitive environments.

Key Features and Components

Activation Mechanisms

Emergency stop devices feature latching systems that stay engaged until manually reset. Activation may occur through push, twist, or key mechanisms, depending on the connector configurations and use case.

Wiring and Connectivity

Proper emergency stop wiring ensures rapid circuit interruption. Connectivity includes incoming air supply lines in pneumatic systems or network connectivity for smart factory integration via PROFINET or similar interfaces.

Latching Systems

Most emergency stop devices use mechanical or electrical latching to prevent automatic resets. This feature is crucial in maintaining a halted state during inspection or repair, ensuring the protection of the process.

Functionality and Operation

How Emergency Stops Work

An emergency stop is connected to a safety control unit. When activated, it interrupts the control circuit, cutting power to the equipment or halting the process until a resetting procedure is performed.

Activation Scenarios

Typical triggers include a detected hazard, system overload, disc surface damage, or a dangerous event requiring immediate shutdown to avoid harm.

Resetting Procedures

Resetting requires manual disengagement, ensuring the hazard has been cleared and equipment is safe to resume operation. This helps maintain compliance with safety protocols.

Application and Use

Industries and Sectors Utilizing E-Stops

Emergency stops are found in manufacturing, pharmaceutical, food processing, automotive, and robotic automation systems, ensuring operational safety in both human and machine-intensive workflows.

Common Use Cases in Factories

Applications include conveyors, assembly lines, and CNC machines, where operators may need to halt operations due to misalignment, obstruction, or unexpected behavior.

Innovations in Smart Factory Safety

Modern E-stop devices integrate with industrial network protocols, enabling real-time diagnostics, remote reset capability, and performance measurement for predictive safety analytics.

Installation and Maintenance

Best Practices for Placement

Devices should be installed within easy reach along machinery and walkways. Strategic positioning minimizes response time during emergencies and reduces installation time and cost.

Routine Inspection and Testing

Routine testing is critical to ensure locking functionality, valve position control, and circuit integrity. Maintenance should include a full installation process review.

Troubleshooting Common Issues

Issues such as false positives, internal faults, or poor contact wear can affect performance. Regular inspection of disc lifts, supply voltage, and connection integrity is vital.

Overview of Schlegel Emergency Stop Devices

Schlegel is a renowned manufacturer of emergency stop buttons, safety switches and contact blocks, recognized for their German-engineered quality, innovation, and compliance with international safety standards. Schlegel’s E-stop solutions are widely used in automation systems, machine control panels, and industrial networked environments, offering robust functionality and enhanced safety.

Features of Schlegel Emergency Stop Pushbuttons

Schlegel emergency stop pushbuttons are available in various actuator styles including mushroom head, key-release, and twist-to-release types. Key features include:

- IP65 to IP69K protection ratings, ensuring high durability in wet, dusty, and rugged environments.

- Mechanical latching systems with reliable disengagement upon reset.

- Options for illuminated actuators to enhance visibility during emergency situations.

- Modular configurations to fit a range of panel designs and connector configurations.

- Designed to integrate with feedback circuits, enabling status monitoring and remote diagnostics.

- Compatible with PROFINET and industrial network protocols for smart factory environments.

- Models with plastic housing or metal front rings, balancing cost-effectiveness and robustness.

- High switching voltage capacity suitable for both low and high power control systems.

These features make Schlegel an excellent choice for manufacturers seeking safety emergency stop devices that combine safety, aesthetics, and long-term performance.

Advanced Design Considerations and Environmental Durability

Modern emergency stop systems are built with critical components like internal contact blocks and replaceable contacts, offering greater reliability and ease of maintenance. Many models feature durable plastic or robust polyester plastic construction, enhancing corrosion resistance and exceptional robustness, especially in external environments and hygienic environments where levels of cleanliness are strictly regulated.

Control Integration and Operator Interfaces

A well-designed operator control station allows seamless human-machine interaction using accessible buttons, colored buttons, or pushbutton switches with push-pull, key-to-release, or lockable actuators. These manual control devices prevent accidental re-activation and protect against damage to machinery or damage to equipment during fault scenarios.

Pushbutton heads in models like the E-STOP pushbutton with the E-STOP symbol help workers identify emergency functions instantly. For enhanced usability, remote emergency options and wire emergency switches provide added flexibility in interlinked machines or large-scale machinery setups.

System Compatibility and Functional Integration

When used in combination with safety relay systems or safety relay units, conventional E-stop switches help form a complete safety circuit that protects human safety and prevents startup of inactive machines during fault diagnosis. These devices are compatible with pilot devices, RMQ Titan interfaces, and cutout switches, allowing easy inclusion in a broader control and monitoring system.

Many units also support additional options like built-in power supply monitoring, IP-rated enclosures, and compatibility with power cords for modular systems. Their role in a properly structured risk assessment is vital in developing essential safety features for any industrial setup.

Durability, Cost, and Lifecycle Considerations

These systems are designed for cost-effective options with replaceable components to extend product life. High-quality emergency switches are rated for thousands of cycles minimum, ensuring durability even in high-usage environments. This long lifespan, combined with a friendly choice of materials made with the environment in mind, contributes to both safety and sustainability.

By integrating these crucial components into your operations, you can significantly reduce downtime, enhance safety compliance, and maintain productivity across all types of machinery and sectors.