Importance of Mechanical Interlocks in Industrial Safety Mechanical interlocks are a crucial safety device in many industrial environments, designed to prevent accidental operation and ensure…

Importance of Mechanical Interlocks in Industrial Safety

Mechanical interlocks are a crucial safety device in many industrial environments, designed to prevent accidental operation and ensure equipment can only be accessed under safe conditions. These systems physically block access to hazardous areas until predefined safety protocols are met.

By integrating safety interlocks into machine guards and control panels, industries can elevate their level of safety and compliance with machine safety standards. Their use is particularly vital in harsh environments and clean environments where reliability and secure locking mechanisms are essential.

Different Types of Safety Interlocks

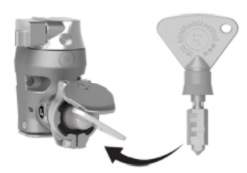

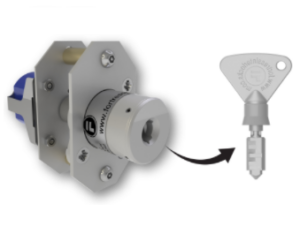

Trapped Key Interlocks

Trapped key interlocks are mechanical safety interlock switches that use a key exchange system to enforce a safe sequence of operations. The key is only released when it’s safe to proceed, providing a strong physical connection to safety logic.

Commonly found in industrial settings, these interlocks are ideal for scenarios where multiple doors or access points need strict coordination. Their design ensures that energy sources are fully isolated before access is granted, minimizing risks.

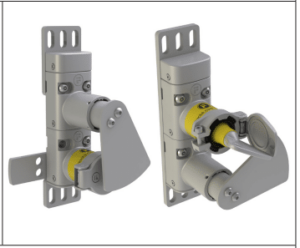

Guard Locking Systems

Guard locking switches maintain machine guards in a locked state until a safe stop condition is achieved. These safety interlocks combine both mechanical and electrical interlocking features to control hazardous areas.

They’re ideal for applications requiring delayed access after machine shutdown, especially when inertia or residual energy presents a risk. Connection type flexibility and housing material options help these devices adapt to a wide range of industrial applications.

RFID Safety Switches

RFID-based non-contact safety switches offer coded access with a high level of safety. These automation products use radio-frequency identification to detect whether the guard is properly closed, without requiring physical contact.

They are suitable for both harsh and clean environments and are increasingly used in industries where tamper resistance and flexibility are priorities.

Electromechanical Interlocks

Electromechanical interlocks blend mechanical interlocking with electrical safety, offering a hybrid solution for diverse industrial environments. They often include features such as IP-rated enclosures and optional monitoring contacts for integration into safety control panels.

These interlocks support various connection types and are well-suited for machines with moving parts where access must be tightly controlled.

Notable Safety Interlock Brands & Products

Overview of DOLD Safety Interlocks

DOLD is known for its high-performance safety interlock switches, engineered to meet demanding machine safety standards. Their product range includes both mechanical and electrical interlocking systems designed for secure and reliable operation in critical zones.

Euchner Safety Gate Systems Explained

Euchner provides a wide range of safety interlocks, including non-contact safety switches and guard locking switch systems. Their interlocks are optimized for use in modern industrial automation systems, with strong emphasis on tamper resistance and safe operation.

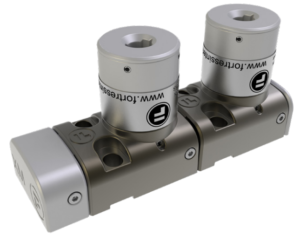

Euchner’s MGB, CET, and CTP Ranges

- MGB (Multifunctional Gate Box): Modular units with mechanical and electrical interlocking, suitable for complex access control.

- CET: Transponder-coded safety switches with electromagnetic locking.

- CTP: Compact safety switches combining mechanical latch with RFID detection for enhanced safety and reliability.

Features of DOLD’s SAFEMASTER Range

DOLD’s SAFEMASTER range includes mechanical safety interlock switches and control units designed for seamless integration into industrial settings. With wide compatibility and robust housing materials, they support a broad range of machine guard and access control applications.

Standards and Compliance

Understanding EN ISO 14119

EN ISO 14119 governs the design and selection of interlocking devices associated with safety guards. It emphasizes the need for effective guard locking mechanisms, tamper resistance, and appropriate connection types.

This standard guides the use of safety interlocks in line with machine safety standards, ensuring they deliver consistent protection and performance in industrial environments.

Technological Advancements in Interlocks

Electromagnetic RFID Guard Locking

Modern interlocks now incorporate electromagnetic force and RFID verification, combining secure locking with identity recognition. These systems eliminate the need for mechanical contact while maintaining a high safety level and enabling faster diagnostics.

Control Stations with Distributed I/O

Distributed I/O control panels allow interlock systems to communicate directly with safety controllers. This setup improves real-time monitoring and simplifies maintenance, especially in large-scale automation environments.

Applications of Safety Interlocks

Guarding Movable Machinery

Mechanical interlock switches are critical for movable machinery, preventing access until motion has completely stopped. These systems enhance safety around robotic arms, conveyors, and automated presses.

Use in Hazardous Environments

In explosive or chemically aggressive environments, safety interlocks must withstand extreme conditions. IP-rated housing material and mechanical interlocking are often preferred in these harsh environments for maximum protection.

Comprehensive Machine Safety Solutions

Safety Controllers

Safety controllers interpret signals from safety interlock switches and ensure coordinated response across machines. They serve as the brains behind automated safety systems.

Safety Mats

Pressure-sensitive safety mats complement interlock systems by detecting operator presence in hazardous zones. When integrated with control panels, they offer an additional safety layer in access-restricted areas.

Emergency Stop Buttons

Emergency stop buttons work alongside safety interlocks to provide immediate shutdown capability. Positioned near interlocked areas, they are essential for quick operator response in emergency scenarios.

Benefits of Safety Interlocks

Protecting Against Unauthorized Access

Mechanical interlocks and safety switches physically prevent unauthorized access to restricted zones. Whether in high-voltage equipment or fast-moving machines, they act as a frontline defense.

Enhancing Operational Integrity

By ensuring only safe operations can occur, interlock systems reduce downtime and damage risks. This helps maintain consistent productivity and supports long-term equipment health.

Promoting a Safe Workplace Environment

A strong interlock system contributes to a culture of safe operation. With clear safety protocols and reliable enforcement through interlocks, workers feel more secure and confident in their environment.