What Are Two-Hand Control Relays? Purpose and Function Two-hand control relays are safety components designed to ensure that operators use both hands simultaneously to initiate…

What Are Two-Hand Control Relays?

Purpose and Function

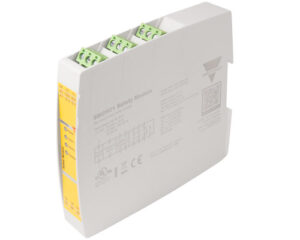

Two-hand control relays are safety components designed to ensure that operators use both hands simultaneously to initiate a machine operation, preventing accidental or hazardous activation. They are widely used in punch presses, cutting machines, and industrial machinery requiring high safety integrity.

How They Work

The operator must press two separate control buttons within a defined time window. If both are not activated properly, the relay will not energize the output, ensuring operator presence and intent.

Key Features of Two-Hand Control Safety Relays

Simultaneity Monitoring

Ensures both input buttons are pressed within 0.5 seconds, maintaining compliance with safety standards like EN 574 Type IIIC.

Anti-Tampering Protection

Advanced models include cross-circuit detection, feedback monitoring, and fault detection to prevent bypassing or short-circuit manipulation.

Integration with Safety Controllers

Often paired with safety relays, contactors, or PLCs to form a complete safety circuit in industrial settings.

Types of Two-Hand Control Relays

Basic Two-Channel Relays

Simple logic-based units with dual input channels for pushbuttons and a single safety output.

Modular Safety Relays

Allow for expansion and integration with light curtains, E-stop buttons, or guard switches for more complex machines.

Category 3 and 4 Safety Relays

Designed for high-risk machinery, offering redundant circuitry, self-monitoring, and fail-safe performance.

Industrial Applications

Press and Forming Machines

Essential for metal forming, hydraulic presses, and cutting applications, where accidental actuation can result in severe injury.

Assembly and Robotic Workstations

Used to ensure hands are away from dangerous zones during machine start-up in automated manufacturing cells.

Packaging Equipment

Prevents unsafe triggering of packaging blades, sealers, or stamping machines during the loading/unloading process.

Compliance and Safety Standards

Two-hand control relays support or comply with:

-

EN ISO 13851 (EN 574) – Two-hand control devices

-

EN ISO 13849-1 – Safety-related parts of control systems

-

IEC 60947-5-1/5-3 – Control circuit devices

They help achieve Performance Level (PL) d or e, depending on integration and redundancy.

Installation and Design Guidelines

Mounting Pushbuttons

Use ergonomic spacing (minimum 260mm) to prevent one-hand operation. Mount at a comfortable height to reduce fatigue.

Circuit Integration

Integrate with feedback loops, output contact monitoring, and muting logic as needed. Ensure dual-channel wiring and tested redundancy.

Reset and Diagnostic Functions

Models may include manual or automatic reset options, LED status indicators, and diagnostic outputs for maintenance efficiency.

Why Choose Venus Automation?

-

Stocking trusted brands like Pizzato, IDEM, and DOLD

-

Relay models with M12 connectors, push-in terminals, and LED diagnostics

-

Expertise in machine safety design, including custom relay panel solutions

Frequently Asked Questions (FAQ)

Q1: What happens if only one button is pressed?

A: The relay will not activate. Both buttons must be pressed within a short time window to initiate output.

Q2: Can I use this with a PLC?

A: Yes, many two-hand control relays are designed for integration with programmable logic controllers and safety monitoring systems.

Q3: What is the minimum spacing between buttons?

A: EN 574 recommends 260 mm or more to prevent activation with one hand.