Introduction to ASO Safety Contact Mat The ASO Safety Contact Mat is a highly responsive safety device designed to detect the presence of personnel in…

Introduction to ASO Safety Contact Mat

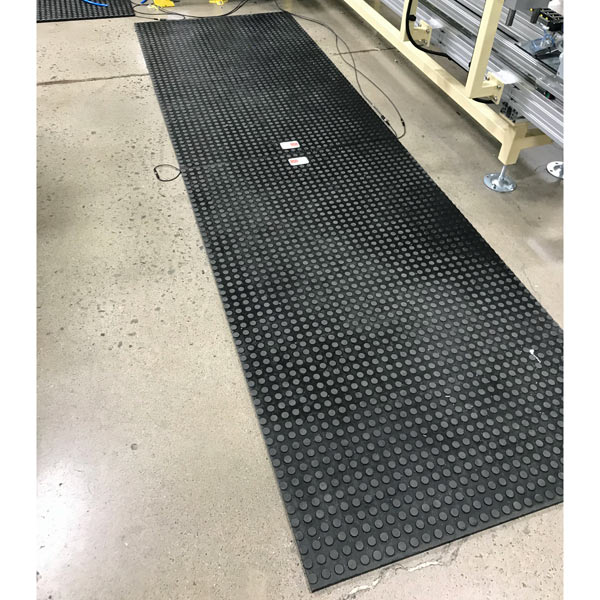

The ASO Safety Contact Mat is a highly responsive safety device designed to detect the presence of personnel in hazardous areas and immediately trigger a machine stop. Ideal for use around presses, robotic cells, and conveyors, these safety contact mats enhance protection in industrial settings where physical guarding may be impractical.

Made from single compound polyurethane material with options for polyurethane black or anti-slip checkered surfaces, ASO mats are designed to withstand mechanical stress and deliver reliable safety feedback. Their layered construction, including internal conductive plates, provides consistent performance over millions of switching cycles, even in high-traffic zones.

With proven resistance to moisture, oils, and chemical contaminants, ASO mats meet the demanding requirements of production automation, transport safety, and machinery control applications.

Key Features of the ASO Safety Contact Mat

Precise Specifications

ASO contact mats are engineered to meet strict safety requirements, providing fast response times, robust durability, and seamless system integration. The mats include fully enclosed electrical resistance circuits using conductive metal plates, ensuring reliable detection with minimal false triggers.

They are compatible with standard safety relays and safety monitoring relays, making them easy to connect into any compliant safety transmission architecture. With their impermeability against oils and excellent resistance to environmental stress, these mats offer dependable safety across a wide range of industries.

High Switching Pressure

Each mat is calibrated for high switching pressure, ensuring it activates only when a defined threshold is met—reducing false positives from dust, vibration, or lightweight items. The robust design allows support of heavy foot traffic and static loads, making it well-suited for facilities where workers may need to stand for long periods or walk over mats with equipment.

ASO’s mats maintain their sensitivity over time thanks to durable materials and reinforced connection cable interfaces. Some models support 2 two-core connecting cables or optional cable exits for custom integration into your system’s safety evaluation control electronics.

Industrials and Commercial Applications

Versatile Use Cases

ASO Safety Contact Mats are designed for a wide range of personnel safety applications, from factory automation lines to commercial access points. Their responsive surface ensures that even brief or partial contact results in an immediate machine stop—ideal for operators working around production automation, robotic cells, or semi-automated workstations.

In production lines, these mats offer a non-intrusive safety solution that can be integrated without altering the workflow. Whether installed at the base of a press or along the perimeter of a conveyor, their slim profile and flexible mounting options make them easy to deploy. When combined with safety relays or safety evaluation control electronics, they provide a reliable, EN-compliant safety layer across various machine types.

Commercial uses include packaging systems, assembly stations, and secure areas requiring limited human access. With support for custom configurations, ASO mats can be adapted to a wide range of operational layouts.

Safety Applications in Different Environments

These safety contact mats excel in both clean and rugged environments. Thanks to their sealed construction and chemical resistance, they are protected against oil, moisture, and dust ingress—making them suitable for machining centers, automotive plants, and safety in transport vehicles.

For sensitive or customer-facing areas, mats can be delivered with anti-slip surfaces, polyurethane contact surfaces, and dot or checkered textures, ensuring stability and aesthetics without compromising performance. They’re also compatible with laminar sections, aluminium cable duct covers, and clipable cable ducts to simplify installation and reduce tripping hazards.

From light-duty electrical enclosures to heavy mechanical demand zones, ASO mats adapt seamlessly to the operational and safety needs of modern industries—reinforcing a higher level of safety in every environment.

ASO Safety Contact Mat Dimensions

| Part Number | Mounting Profile | Connecting Plug |

|---|---|---|

| SENTIR Mat | 1000mm x 750mm | 2 x 0.34 cable sheathing of black PU |

| SENTIR Mat | 1000mm x 1000mm | 2 x 0.34 cable sheathing of black PU |

| SENTIR Mat | 1000mm x 1500mm | 2 x 0.34 cable sheathing of black PU |

Advantages of Using the ASO Safety Contact Mat

Robust Construction

ASO Safety Contact Mats are engineered with a single compound polyurethane material that provides high structural integrity and uniform pressure sensitivity. The core includes conductive plates or internal metal plates, ensuring full-surface activation across the mat. Each layer is tightly bonded to prevent delamination, while the outer layer resists abrasion from boots, trolleys, or machinery traffic.

This robust construction allows the mat to absorb constant physical stress without loss of function—ideal for high-traffic areas and mechanical demand applications.

Reliable Performance

The mats are built to respond instantly upon contact, providing fast and accurate activation with every step. Calibrated for optimal switching pressure, they minimize false triggers from vibrations or light debris while ensuring that any human contact immediately interrupts machine motion.

Their precise response time and compatibility with safety monitor relays or safety relays make them suitable for systems requiring consistent, repeatable safety actuation. Even after extended use, the mats retain their electrical resistance characteristics and switching cycles consistency.

Enhanced Durability

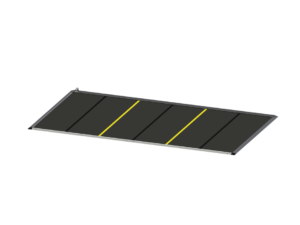

Designed for longevity, ASO mats are resistant to puncture, fatigue, and edge curling. They maintain form under static load and foot traffic, making them ideal for long-shift environments or areas with continuous occupancy. Models with fixation rails, built-in ramp rails, or reinforced corners add structural stability and reduce wear in critical contact zones.

Combined with annual function tests and simple wiring instructions, these mats offer low-maintenance operation over their service life—helping to reduce downtime and replacement costs.

Chemical Resistance

Industrial environments often expose equipment to harsh substances, but ASO mats are specifically designed for chemical resistance. They offer impermeability against oils, solvents, and mild acids, preventing degradation over time. This ensures consistent performance even when installed in zones exposed to coolants, cleaners, or chemical contaminants.

Their sealed construction and polyurethane black surface layer resist absorption, making them easy to clean and safe for use in environments with strict hygiene requirements.

Integration and Functionality

Accessories for Seamless Integration

ASO Safety Contact Mats are designed to integrate easily into modern automation and safety control systems. A wide range of accessory components supports clean and safe installations, including M8 sensor cables, connection cables, and fixation rails. For wiring flexibility, mats support optional cable exits, clipable aluminium cable ducts, and 2 two-core connecting cables.

ASO also offers tailored mat configurations and cable sheathing options that protect signal integrity in high-interference environments. These accessories simplify electrical integration and enhance protection of the entire switching circuit, particularly when combined with safety monitoring relays or ELMON Safety Relays.

Installation Process

The installation process is straightforward and supported by detailed instruction manuals and wiring instructions. Mats are typically installed over finished floors using built-in ramp rails or fixation rails to prevent slippage and reduce trip hazards. Surfaces should be clean, dry, and flat for optimal performance.

Mats can be connected in series for larger coverage areas, and connection to safety evaluation control electronics is typically handled through standard M8 connectors. ASO provides full support for custom configurations, making the installation adaptable to nearly any workspace or production layout.

Maintenance Guidelines

ASO mats are engineered for long life and low maintenance. Routine checks should include visual inspections for wear or damage, verification of electrical continuity, and validation of switching pressure thresholds. It’s recommended to conduct an annual function test as part of your safety protocol.

Mats should be kept clean from debris and checked for signs of edge curling, delamination, or cable strain. If exposed to chemical contaminants, use appropriate cleaning agents compatible with polyurethane contact surfaces. Following these guidelines ensures continued compliance with safety regulations and minimizes warranty claims due to user neglect.

Safety and Compliance

ASO Safety Contact Mats are built to meet or exceed international safety requirements for tactile safety devices. They comply with standards such as EN 1760-1 and ISO 13856-1, covering electrical sensitivity, switching reliability, and operator protection.

Each mat is thoroughly tested for electrical resistance, response time, and mechanical durability before shipment. Models are available with type approval and documentation verifying their use in regulated industrial environments. This ensures confidence in compliance during inspections or audits and provides peace of mind in critical safety functions.