Description

Understanding Multipole Connectors in Modern Systems Multipole connectors are essential in today’s industrial and automation landscapes, offering a reliable and compact way to manage multiple…

Understanding Multipole Connectors in Modern Systems

Multipole connectors are essential in today’s industrial and automation landscapes, offering a reliable and compact way to manage multiple electrical connections within a single housing. Whether used in control panels, field devices, or machinery, these electrical connectors streamline cabling, improve system modularity, and simplify maintenance. Their ability to carry multiple signals—power, data, or control—through one connection point makes them ideal for high-density wiring environments with compact design requirements. Multipole systems also support a secure and standardized power connection between components.

Introduction to Multipole Connectors

Multipole connectors are electrical interfaces designed to connect several circuits using one unified connector body. Available in various configurations—such as circular or rectangular—they can handle both signal and power transmission across numerous industrial applications. Often referred to as multi-pin or multipin connectors, they are used where compactness, durability, and performance are required in harsh or space-constrained settings.

Common use cases include:

- Industrial automation systems

- Robotic assemblies

- Power distribution modules

- Control cabinets and sensor hubs

Their popularity stems from a standardized pin layout, optional locking mechanisms, and compatibility with a wide range of termination methods like screw, crimp, and solder. Wieland Electric is a prominent supplier of multipole and power connectors used in these setups, offering solutions with verified current ratings and a variety of contact surface finishes.

Importance of Multipole Connectors

Multipole connectors play a critical role in ensuring safe and organized electrical connectivity in complex systems. Instead of relying on multiple single-pin connections, engineers can consolidate cables, reduce wiring errors, and speed up deployment. This not only lowers installation costs but also boosts uptime by enabling faster troubleshooting and modular upgrades. Wieland Electric’s advanced connector range with female inserts simplifies integration and ensures reliability.

In environments such as manufacturing plants or automated warehouses, where reliable connectivity is vital, the robust design of heavy-duty multipole connectors offers added protection against mechanical stress, vibration, and exposure to dust or moisture. Circular connectors are especially common in these settings due to their space-efficient design and ease of connection.

Key Features of Multipole Connectors

Configuration flexibility

Multipole connectors are available in a broad range of pole counts, allowing engineers to select the exact number of contacts required for a given application. Whether it’s a 3-pin setup for basic connectors handling control signals or a 24-pole arrangement for more complex systems, this flexibility supports efficient wiring without overengineering. Modular designs also enable easy adaptation as system needs evolve, which is especially valuable in scalable automation frameworks. A wide variety of models ensures the right fit for any technical requirement.

Ingress protection

Many multipole connectors come with high IP ratings, such as IP65 or IP67, providing dependable protection against water, dust, and oil. This makes them ideal for outdoor installations, washdown environments, or industrial zones exposed to contamination. Waterproof multipole connectors with sealed gaskets or locking sleeves ensure system reliability even in the most demanding conditions, including heavy machinery or transport infrastructure.

Installation efficiency

These connectors are designed for fast, tool-less installation in many cases, minimizing assembly time and human error. Pre-terminated connectors or those with screw less terminals help reduce setup time on production lines or in field service. Moreover, clearly marked pin configurations, polarized mating interfaces, and snap-in locking features contribute to consistent and error-free wiring practices. Removal tools are available for maintenance and disconnection without damaging the contacts or housings. Wieland Electric provides optional removal tools tailored to their female inserts and modular connector designs.

Types of Multipole Connectors

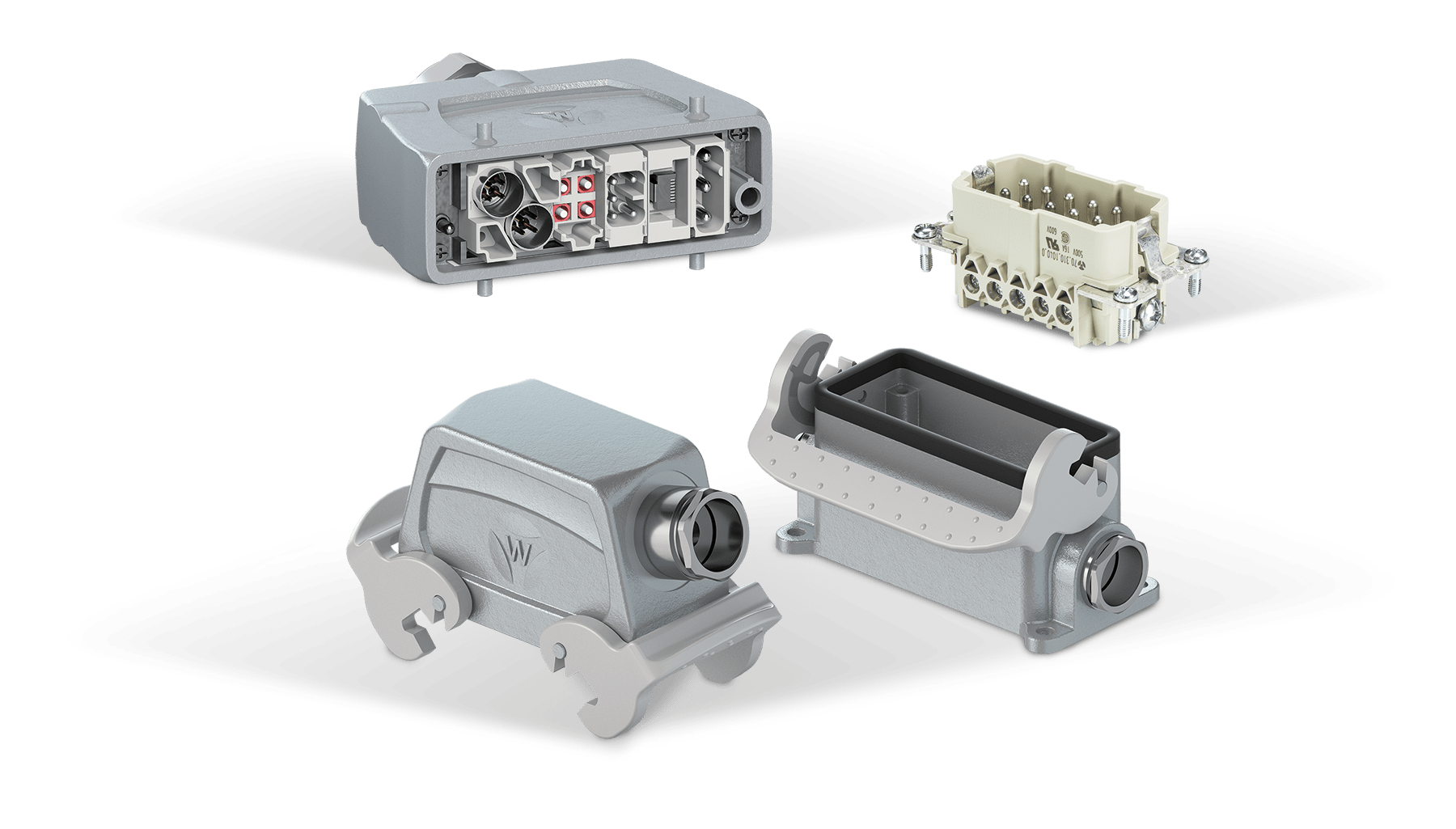

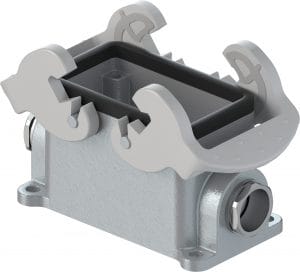

Heavy-duty multipole connectors

Heavy-duty multipole connectors are engineered for use in rugged industrial environments, offering superior resistance to vibration, mechanical stress, and high current loads. Typically housed in metal enclosures, these connectors are ideal for machine tools, production lines, and control panels that operate under continuous or heavy-duty conditions.

Key benefits include:

- High power and signal contact options

- Robust locking mechanisms

- Compatibility with modular inserts and mounting frames

Brands like Wieland Electric offer heavy-duty variants that meet IEC 61984 standards for safety and reliability in industrial control systems. Their female inserts ensure consistent contact performance and safe power connection.

Multi-pin thermocouple connectors

These specialized multipole connectors are used to manage multiple thermocouple inputs or outputs within a single compact housing. Each contact pin is matched to the thermocouple type (e.g., Type K, J, T), maintaining signal accuracy and preventing junction errors. Multi-pin thermocouple connectors are often used in process control, environmental chambers, and industrial ovens where multiple temperature readings need to be captured simultaneously.

They are available in:

- Miniature and standard form factors

- Color-coded insulators for type identification

- Panel mount or cable-mount variants

Waterproof solutions

Waterproof multipole connectors are essential for outdoor installations, marine environments, or washdown zones in food and beverage production. These connectors are typically rated IP67 or higher and use sealed gaskets, O-rings, or gel-filled chambers to prevent moisture ingress.

Applications include:

- Outdoor lighting systems

- HVAC units exposed to the elements

- Industrial sensor networks in wet conditions

Waterproof connectors with quick-disconnect features offer both protection and efficiency, reducing the need for enclosures and enabling fast maintenance or replacement. Circular connectors with waterproofing are particularly valued for their quick installation and reliable performance.

Applications of Multipole Connectors

Industrial applications

In industrial environments, multipole connectors are foundational to system integration and control. They streamline complex wiring between PLCs, sensors, motors, and control cabinets, reducing space and ensuring clear signal paths. Heavy-duty multipole connectors are commonly used in:

- Assembly lines and robotic cells

- Factory automation systems

- Power distribution panels

- Control and instrumentation modules

Their high current capacity, mechanical durability, and IP-rated protection make them indispensable in harsh industrial conditions. Wieland Electric connectors are frequently used in these systems due to their reliability, flexible cable entry options, and support for safe power connection.

Audio and broadcast applications

Multipole connectors also play a significant role in professional audio, video, and broadcast setups. Multi-pin audio connectors are often used to carry multiple balanced audio channels, power, or control signals within one cable—ideal for stage setups, film production, or studio environments.

Applications include:

- Intercom systems

- Multi-channel microphone arrays

- Broadcast camera rigs and lighting control systems

Their compact form factor and secure latching systems ensure reliable connections under frequent handling and movement. Circular connectors are commonly preferred in these applications due to their durability and ease of use.

Consumer electronics

In the consumer electronics space, multipole connectors are commonly found in devices that integrate multiple functions into a single interface. These connectors enable compact internal wiring in products like:

- Laptops and docking stations

- Game consoles

- Smart appliances

- Wearable technology

Designs prioritize space efficiency, signal clarity, and ease of assembly, with many multipole connectors in this sector using fine-pitch terminals, female inserts, and low-profile housings with cable entry designs optimized for compact electronics. A wide variety of miniature and board-mount circular connectors are also used in this sector to achieve dense packaging and portability.

Safety and Certification

TÜV-certified safety programs

TÜV certification is a globally recognized mark of safety and quality assurance. Multipole connectors that are TÜV-certified have undergone third-party testing to verify their compliance with international safety standards, such as IEC 61984 for industrial connectors. These certifications are particularly important in applications involving high voltages, critical signal paths, or human-machine interfaces.

Key reasons to prioritize TÜV-certified multipole connectors:

- Verified performance under fault conditions

- Approval for use in safety-critical machinery

- Compliance with EU directives and global export requirements

TÜV certification also strengthens buyer confidence and simplifies procurement for OEMs, system integrators, and control panel builders. Wieland Electric offers TÜV-certified multipole connectors that meet global compliance standards.

Reliability in challenging conditions

Multipole connectors are often deployed in environments where exposure to dust, moisture, vibration, or extreme temperatures can compromise electrical integrity. Certified connectors are built to withstand these elements while maintaining reliable operation over time.

Features that enhance reliability in harsh environments include:

- High ingress protection (IP65/IP67 or higher)

- Flame-retardant and impact-resistant housings

- Corrosion-resistant metal shells and contacts with robust contact surface treatments

These features are vital in sectors such as mining, transportation, and food processing, where failure could lead to safety hazards, equipment damage, or costly downtime. Wieland Electric’s components with premium contact surfaces and rated current capacities are engineered to maintain stability in these demanding scenarios.