19

Streamlining EV Electrical Installations. Discover the Power of the Wieland Podis® Flat Cable System

Wieland Podis Flat Cable System

OVERVIEW

As the electrical industry continues to evolve, innovations that promise efficiency, reliability, and cost-effectiveness are increasingly essential. The Wieland Podis® flat cable system is one such innovation, redefining how electrical installations are approached, particularly in industrial and commercial environments. As a distributor of this advanced system, Venus Automation is excited to showcase its numerous benefits and applications. Here, we delve into what the Podis® flat cable system is, how it works, and why it stands out in the market.

As the demand for electric vehicle (EV) infrastructure grows, efficient and scalable electrical installation solutions are essential. The Wieland PODIS Flexible Power Bus is a game-changer in streamlining EV charging installations, providing a decentralized power distribution system that significantly reduces cabling complexity and installation time. Unlike traditional wiring methods, this system utilizes a flat cable design, allowing quick and tool-free connections without the need for extensive conduit runs.

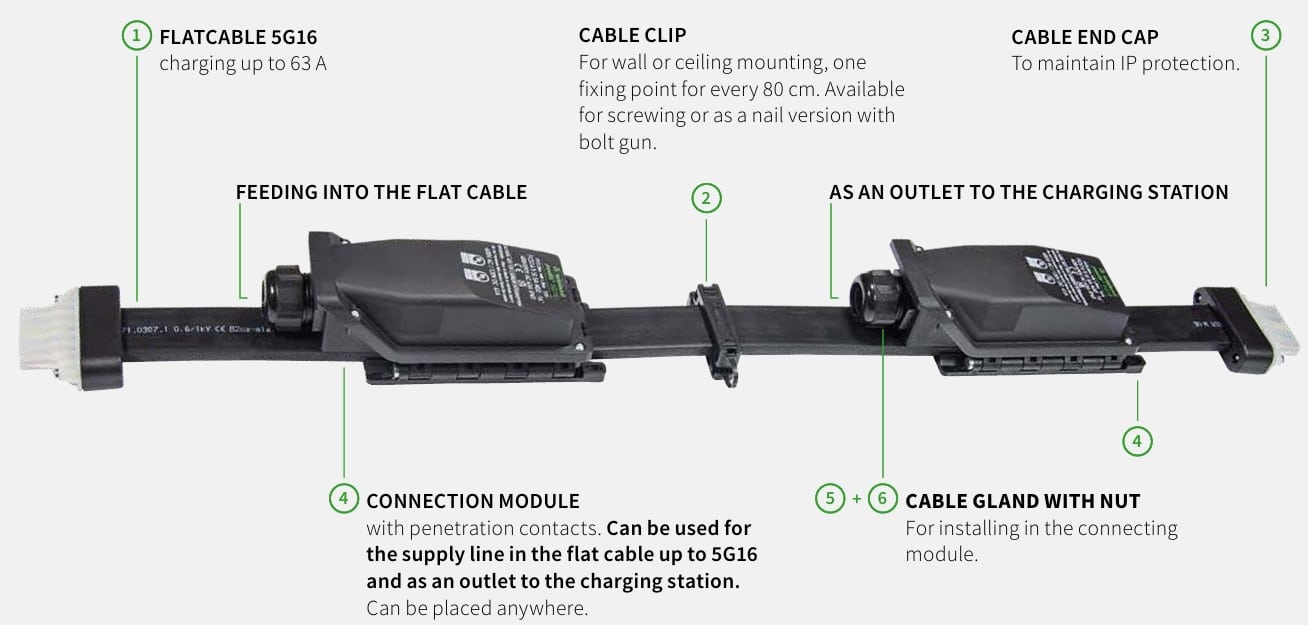

A key component of this system is the Flat Cable Li2HH 5G16, designed for high-performance power distribution while ensuring durability in demanding environments. The system is further enhanced with modules such as the Connecting Module FCS 16 5 SA SAM50K and the Connecting Module FCS 16 5 SI SA M32, which provide quick and secure power tap-offs, minimizing labor-intensive installation processes.

To ensure a reliable and safe termination, the Cable End Cap Podis 5G16 protects exposed cable ends, maintaining system integrity. With its plug-and-play connectivity, similar to the indoor-focused Wieland GESIS Easy Plug-in System, the Podis® Flat Cable System sets a new standard for efficient EV electrical installations.

what is the wieland podis flat cable system?

The Podis® flat cable system by Wieland Electric is a decentralized power distribution solution designed to simplify and enhance electrical installations. Unlike traditional systems that rely on numerous round cables and extensive wiring, the podis® system uses flat cables that can connect multiple devices along a single supply line. This system is particularly beneficial for EV charging stations, industrial automation, and building infrastructures like parking garages and production facilities. Below is a photo of a general installation with conventional wiring.

Features

Accessories

- Outgoing module with conventional wiring

- Wiring the connection modules at the installation site

- Connection cross-section of the outgoing cable 1,5-16 mm

- Rated current 63A and voltage up to 690V

- Flat Cable 5G16 | 00.771.0307.1

- Cable Clip Screw | 05.569.7453.0

- Cabe end cap | Z6.563.6553.0

- Connection module with cut-out for cable gland | 75.456.0053.1

- Cable gland 18-25 mm | Z5.507.1653.1

- Nut | 05.505.0353.1

How does it work?

The Podis® system operates through a modular, pluggable design that simplifies installation and maintenance. It utilizes a tray cable power bus that connects various power modules, enabling easy integration of components without the need for extensive cabling or complicated setups. The system’s piercing contacts allow for quick and secure connections, eliminating the need for stripping and terminating wires. This design not only speeds up installation but also reduces the potential for errors, ensuring a reliable and robust power distribution network.

Special Features and Implementation

Decentralized Power Distribution

The Podis® system’s decentralized design allows for power distribution across various points in a facility without the need for extensive cabling. This feature simplifies the overall wiring architecture and reduces material costs.

A standout feature of the Podis® system is its piercing contacts, which enable connections to be made without cutting or stripping the cable. This innovation reduces installation time and potential errors, enhancing the overall reliability of the system.

The modular design of the Podis® system supports easy expansion and reconfiguration. Components can be added or moved without significant alterations to the existing setup, making it ideal for dynamic industrial environments.

The plug-and-play nature of the Podis® system simplifies the installation process, allowing for quick and hassle-free setups. This feature is particularly beneficial in time-sensitive projects where minimizing downtime is crucial.

The flat cable design requires less space compared to traditional round cables, making it suitable for installations in confined areas such as underground car parks or compact industrial environments.

Key Features and Benefits

The modular design of the Podis® system significantly reduces installation time. By using piercing contacts and pre-assembled cable sets, the system can be set up quickly and efficiently, reducing labour costs and minimizing downtime. This efficiency and speed in installation are crucial in large-scale industrial projects where time is of the essence.

Flexibility is another major advantage of the Podis® system. The system’s pluggable modules allow for easy modifications and expansions, which is vital for environments where changes and upgrades are frequent, such as in industrial automation and building technology. This means that the Podis® system can adapt to the evolving needs of a facility without requiring a complete overhaul of the existing infrastructure.

Cost-effectiveness is also a significant benefit of the Podis® system. By simplifying the installation process and reducing the need for extensive cabling, the system cuts down on both material and labour costs. Studies have shown that it can reduce installation costs by up to 75% compared to traditional methods.

These savings can be particularly impactful in large-scale projects where budget constraints are a common concern.

With fewer connections and cables, the Podis® system minimizes the risk of electrical faults. The use of high-quality materials and precise engineering ensures long-term reliability and safety in various applications. This enhanced reliability and safety are crucial in environments where consistent power distribution is critical to operational success.

Applications

Industrial

The Podis® system is versatile and adaptable, making it suitable for a wide range of industrial applications. Here are some key areas where the system excels:

Airport Logistics

In airport logistics, the Podis® system is used extensively for baggage handling systems. Its decentralized power distribution and easy installation make it ideal for this application, where reliability and efficiency are paramount. Major airports like Jeddah King Abdulaziz International and London Heathrow have successfully implemented the Podis® system to enhance their baggage handling operations.

Automotive Industry

The automotive industry benefits from the Podis® system’s ability to streamline production lines. It supports various conveyor technologies, including skid, floor, and roller conveyors. The system’s modular nature allows for quick reconfigurations and expansions, ensuring high plant availability and reduced downtime during maintenance.

Wind Energy Systems

Wind energy installations, including tower and nacelle electrification, benefit from the Podis® system’s robust and flexible design. It supports the integration of lighting, fieldbus control, and emergency lighting, ensuring safe and efficient operations in harsh environments.

Specialised Applications

Intralogistics

In intralogistics, where efficient material handling is critical, the Podis® system offers seamless power distribution for various conveyor systems. It simplifies the integration of sensors, motor starters, and control modules, making it easier to manage and expand logistic operations.

Mechanical Engineering

For mechanical engineering applications, the Podis® system supports complex machinery setups. It provides reliable power distribution, remote motor starting, and fieldbus control, reducing the complexity and increasing the flexibility of machine installations.

Cranes, Shaft and Tunnels

The system is also ideal for power distribution in cranes, shafts, and tunnels. Its robust design ensures high operational reliability and simplifies on-site diagnostics and maintenance, crucial for these demanding environments.

Conclusion

The Wieland Podis® flat cable system represents a significant advancement in electrical installation technology. Its modular, flexible, and efficient design addresses many of the challenges associated with traditional wiring methods. By reducing installation time, costs, and complexity while increasing reliability and safety, the Podis® system is an invaluable asset in various industrial and commercial applications. Venus Automation is proud to distribute this innovative solution, helping our clients achieve their operational goals with greater ease and efficiency. Explore the potential of the Podis® system and transform your electrical installations today.

Expanding the Power of Podis® with Automation Integration

To further enhance the benefits of the Podis® flat cable system, Venus Automation also offers a complete portfolio of industrial automation components that complement decentralized power distribution. These products ensure streamlined integration of control, communication, and monitoring systems—vital for environments where power and automation must operate in perfect synchrony.

In addition to safety-related products, Venus Automation stocks a comprehensive range of items focused on advanced automation technologies. These offerings enable cost reduction and improved operational efficiency; however, they do not eliminate the need for hard-wired safety systems, even when certain technologies may appear similar in function. Automation components serve as powerful tools for enhancing productivity across industrial environments.

For example, Programmable Logic Controllers (PLCs) are essential for automating the operation of industrial machinery. Venus Automation supplies a variety of PLCs from Mitsubishi, including the Alpha Series, FX Family Series, Q Series, IQ-R Series, and Networking CC-Link modules—each designed to support specific control and scalability needs. To complement these systems, light curtains for measurement are available, along with a wide selection of encoders. These include absolute encoders, incremental encoders, magnetic encoders, and rotary encoder types, all of which contribute to precise and reliable automation. When paired with compatible motors, variable speed drives offer enhanced motor control, increasing the value of encoder feedback. For even greater precision, servo motors and servo amplifiers are also available, supporting applications that demand accurate motor positioning.

Human-machine interaction is enabled through a full range of operator interface components, including selector switches, HMI touch panels, handheld pendants, industrial-grade pushbuttons, panel mounts, and relevant accessories. Monitoring of electrical circuit performance is supported by devices such as power relays, speed monitors, insulation monitors, current monitors, battery monitors, phase sequence relays, voltage monitoring relays, and undercurrent relays. Additional core components include power supplies and residual current transformer units. EV charging solutions are also available within this category.

Supporting both automation and safety systems is a robust offering of cables and connectors. This includes straight cables, angled cables, and multipole connectors such as REVOS and RST. For secure integration into control panels, Selos terminals are recommended. A complete range of plugs, sockets, inlets, flanges, couplers, and enclosures are also stocked to accommodate diverse industrial applications.

Click to view our products