9

LOCK IN NOW. FORTRESS SAFETY.

Fortress Trapped Key Systems

Mechanical Magic in Industrial Environments

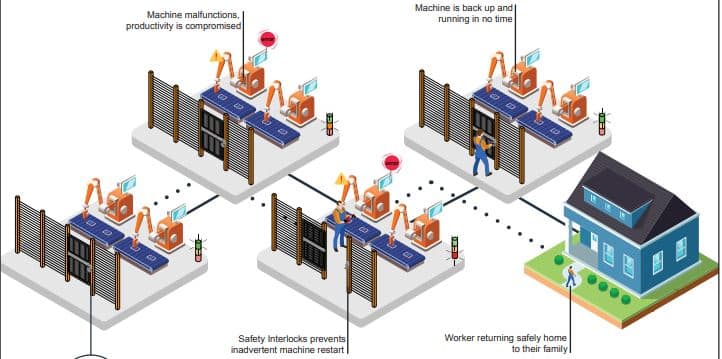

Mechanical systems play a vital role in ensuring safety in industrial automation by providing physical safeguards and controls. Components like safety interlocks, emergency stop mechanisms, and protective enclosures prevent accidental contact with moving parts and reduce the risk of injuries. Properly designed mechanical systems also include fail-safes and redundant features to handle malfunctions, protecting both workers and equipment. Regular maintenance and inspections of these systems are crucial for identifying potential hazards and ensuring ongoing safety compliance. By integrating robust mechanical safeguards, industrial automation systems enhance overall safety, minimizing risks and ensuring a secure working environment.

Industrial safety demands robust and fail-safe solutions to prevent unauthorized access to hazardous areas and ensure controlled machine operations. Trapped Key Systems are at the forefront of this safety innovation, offering a mechanical, key-driven approach to access control that eliminates the risk of human error and ensures strict adherence to safety protocols. These systems are designed to enforce sequential operations, allowing personnel to safely enter restricted areas only when machinery is in a secure state.

Among the most reliable solutions available, Blocking Devices enhance safety by physically preventing access to dangerous zones until specific conditions are met, ensuring compliance with industry standards. Additionally, integrated Control Pads provide seamless operator interaction, enhancing the efficiency of safety mechanisms while maintaining ease of use.

For facilities requiring secure key management, Trapped Key Exchange solutions help prevent unauthorized key removal, reinforcing a structured safety process. With a range of Trapped Key Accessories available, these systems can be customized to fit specific operational needs, making them indispensable for industries that prioritize workplace safety and risk mitigation.

Trapped key systems are safety mechanisms used in industrial automation to ensure secure and controlled access to hazardous areas. They involve a series of interlocking devices where keys are physically trapped until safety conditions are met, preventing unauthorized access or operation. This system enhances safety by ensuring that machinery cannot be operated until all safety measures are in place.

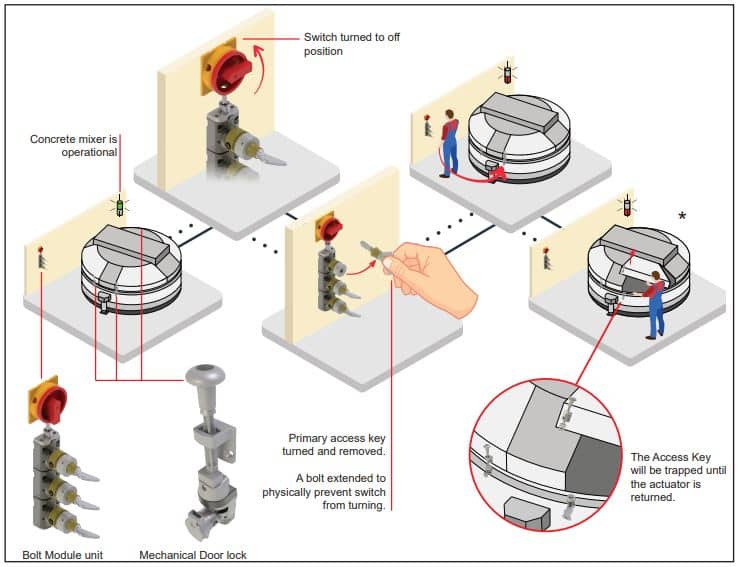

Operations of a trapped key system:

Isolation of power:

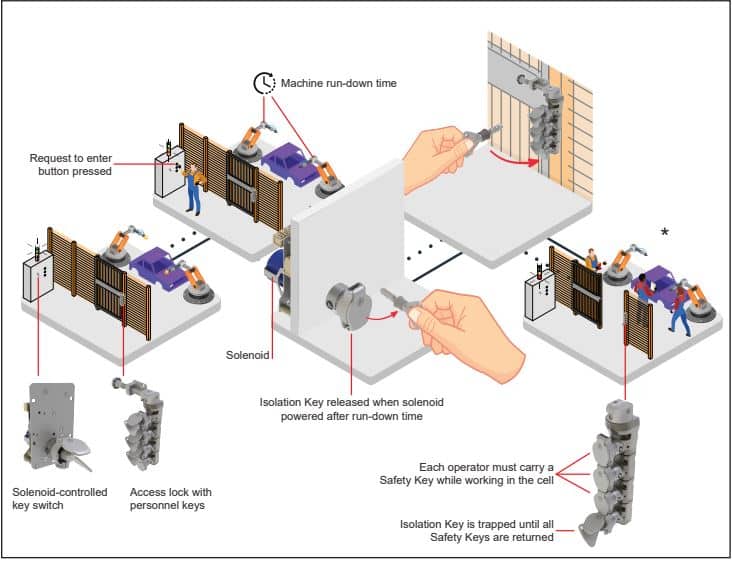

The safe sequence begins with isolating a power source, allowing access through a gate to a high-risk area. When the machine powers down, only then will it be safe to access the hazardous area.

Transfer of keys:

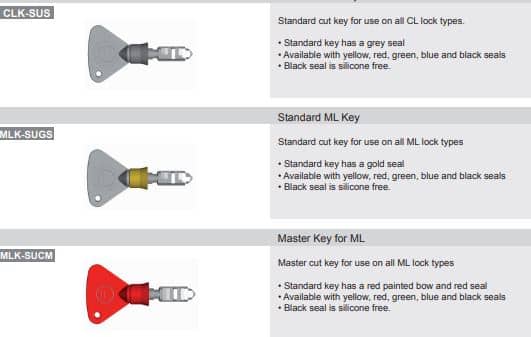

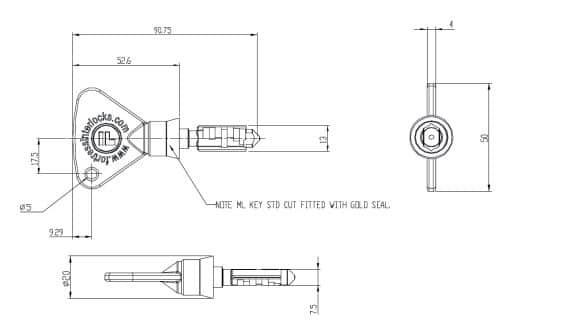

Keys are physically transferred in a sequential order, with various types of keys ensuring that the initial key can only be retrieved after all keys have been returned in sequence and personnel are clear of the hazard.

Safety Standards and Compliance:

Trapped key systems are well designed mechanical safety systems that are validated according to international safety standards (e.g., ISO 13849, IEC 61496) and local regulations (e.g., AS/NZS 4024 in Australia, EN 61496 in Europe). These standards ensure that trapped key safety systems provide reliable safety functions and meet the required performance criteria.

The safe sequence begins with isolating a power source, allowing access through a gate to a high-risk area. When the machine powers down, only then will it be safe to access the hazardous area.

Keys are physically transferred in a sequential order, with various types of keys ensuring that the initial key can only be retrieved after all keys have been returned in sequence and personnel are clear of the hazard.

Trapped key systems are well designed mechanical safety systems that are validated according to international safety standards (e.g., ISO 13849, IEC 61496) and local regulations (e.g., AS/NZS 4024 in Australia, EN 61496 in Europe). These standards ensure that trapped key safety systems provide reliable safety functions and meet the required performance criteria.

KEY INFORMATION ABOUT Trapped key systems:

- Trapped key systems involve a series of locks and keys where each key is unique and can only be released or trapped under specific conditions.

- These systems typically consist of multiple interlocking components such as switches, gates, or doors that must be operated in a specific sequence to control access or start machinery.

- Trapped key systems are designed to comply with safety standards like AS 4024.1, AS/NZS 4024.2019 and ISO 14119 , ensuring they meet strict safety requirements to prevent accidents caused by unauthorized access or improper machine operation .

- Common applications include controlling access to dangerous machinery, ensuring safe maintenance procedures, and managing complex operations where safety is paramount. By ensuring that certain steps are followed in a specific order, trapped key systems help prevent accidents caused by unintended access, equipment start up, or exposure to hazardous environments.

- Examples: Guarding of machines, Access control during machine operations and safety interlocking with other safety devices.

- The operation usually requires keys to be released in a predetermined sequence. For example, to access a hazardous area, a worker might need to remove a key from a control panel, insert it into a gate lock to open the gate, and then use that key to release another key that allows machinery to be operated.

- Trapped key systems involve a series of locks and keys where each key is unique and can only be released or trapped under specific conditions.

- These systems typically consist of multiple interlocking components such as switches, gates, or doors that must be operated in a specific sequence to control access or start machinery.

- Trapped key systems are designed to comply with safety standards like AS 4024.1, AS/NZS 4024.2019 and ISO 14119 , ensuring they meet strict safety requirements to prevent accidents caused by unauthorized access or improper machine operation .

- Common applications include controlling access to dangerous machinery, ensuring safe maintenance procedures, and managing complex operations where safety is paramount. By ensuring that certain steps are followed in a specific order, trapped key systems help prevent accidents caused by unintended access, equipment start up, or exposure to hazardous environments.

- Examples: Guarding of machines, Access control during machine operations and safety interlocking with other safety devices.

- The operation usually requires keys to be released in a predetermined sequence. For example, to access a hazardous area, a worker might need to remove a key from a control panel, insert it into a gate lock to open the gate, and then use that key to release another key that allows machinery to be operated.

Trapped key system applications:

Sequential Interlocking Systems: These systems ensure equipment or machinery can only be operated in a predetermined sequence by requiring keys to be used in a specific order. For example, to start a process, a key must first be used to isolate power, then used to unlock a gate, and finally used to activate machinery.

Access Control Systems: Used to control access to hazardous areas, these systems require keys to unlock gates or doors leading to restricted zones. Keys are released in a sequence that ensures safety, such as ensuring the gate is closed before accessing the hazardous area.

Time Delayed Systems: These systems introduce a time delay between key releases, adding an additional layer of safety. For instance, a key may only be released to unlock machinery after a specified time delay following isolation of the power source.

Trapped key system examples:

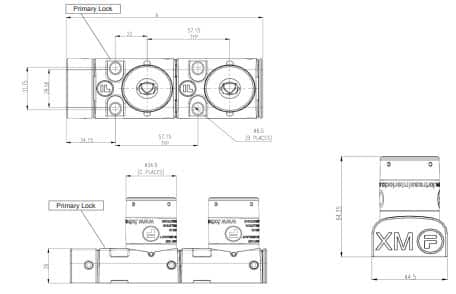

mGard is the specific range of mechanical trapped key systems designed by Fortress interlocks that are suitable for Ple/Cat. 4 or SIL 3. mGard presents a comprehensive range of robust mechanical trapped key products. These systems use purely mechanical access locks, eliminating the need for expensive wiring. mGard’s modular interlocking solutions are suitable for applications up to SIL3 (EN/IEC 62061), Category 4, and PLe (EN/ISO 13849-1), making them ideal for harsh environments. With a testing standard of 1,000,000 operations, the XMS stainless steel mechanical lock module is designed for use in all Ex hazardous areas, operating without power or heat generation. All materials used in mGard products have been extensively tested and verified.

From Mechanical Lockouts to Intelligent Safety Response: Explore Output Solutions

Trapped key systems provide a robust mechanical foundation for safe access and operational sequencing—but safety doesn’t end at interlocks. The safety monitoring and output range at Venus Automation provides tailored solutions to meet the needs of diverse machines and projects.

A key component in modern safety systems is the safety PLC. These programmable devices allow custom safety logic, with flexible input/output terminal assignments. Venus Automation offers a variety of models, including the MOSAIC PLC from Reer, Samos PLC from Wieland, and GEMNIS PLC from Pizzato—each delivering advanced and reliable safety functionality.

Where complex programmability is unnecessary, alternative options such as the safety relay range are available. This includes standalone relays, time-delay relay, speed-monitoring relay, standstill monitoring and timer, PCB relay, relay expansion modules, and control relays like the emergency stop relay, safety edge relay, light curtains relay, and two-hand control relay. These options provide effective and application-specific safety responses.

Essential manual inputs such as the emergency stop remain integral to any safety architecture, despite lacking an automatic safety input. Venus Automation supplies complete solutions including emergency stop accessories, pushbuttons, two-hand stops, and specialized devices like the rope pull emergency stop. For modern installations, wireless safety systems, including wireless emergency stop units, remote controls and accessories, are also available.

Critical integration elements such as contact blocks are supplied to ensure seamless circuit connections. Additional safety monitoring components include the safety encoder, which monitors motor speed, and interlock devices such as tongue solenoid interlock switch and electro-magnetic switches. For more complex safety guarding, multifunctional gatebox units provide a consolidated interface, easily mounted on protective enclosures like concertina guards.

Access restriction and control can also be achieved through electronic key systems, ensuring machinery operates only under authorized conditions. Finally, for output-side protection, safety contactors and pneumatic safety valve solutions are available to ensure reliable machine stoppage when hazardous conditions are detected.

Click to view our product Range