Safety light curtain connection boxes are critical components for simplifying the wiring, control, and integration of safety light curtains in industrial environments. These boxes serve…

Safety light curtain connection boxes are critical components for simplifying the wiring, control, and integration of safety light curtains in industrial environments. These boxes serve as a centralized hub that connects emitters, receivers, muting sensors, and external control units. Their primary role is to streamline installation, reduce wiring errors, and enhance overall system reliability.

In high-risk environments such as packaging lines, robotic work cells, or automated conveyors, proper wiring and integration of safety devices are non-negotiable. Connection boxes ensure the safety light curtain system remains compliant with safety standards like Category 4 / PLe and SIL3.

Advanced models such as the ReeR JANUS MJBOX series offer integrated muting functions, restart override features, and dual normally-open (NO) contacts, making them suitable for systems requiring complex safety logic and signal coordination. Similarly, the MX Light Curtain Interface Box provides reliable connectivity for various configurations and safety controllers.

Key Features and Components of Light Curtain Connection Systems

Modern safety light curtain connection systems are engineered to meet the rigorous demands of industrial environments. Some of the essential features include:

- Integrated Muting Control: Critical for palletizing systems or material transport, the muting function allows the temporary disabling of safety outputs under safe and pre-defined conditions.

- Restart Override Functions: Prevents automatic restart after a fault, ensuring manual confirmation and greater operational control.

- Pre-Wired M12 5-Pole or 8-Pole Connectors: Enables plug-and-play installation with minimal setup time.

- Diagnostic LED Indicators: Offer quick visual status of connection integrity, fault detection, and device alignment.

- Tamper-Proof Locking Screws and Mounting Brackets: Designed for secure installations with protection against unauthorized adjustments.

Many connection boxes include support for programmable logic controllers and integrate easily into broader machine safety systems. Options such as single-ended or double-ended cables (e.g., F39-JD7A-D or F39-JD10B-L) cater to varied installation lengths and configurations.

Broader integration with Safety & Automation Systems

In modern industrial environments, just safety light curtains (standard or muting) and their connection boxes are only one part of an integrated safety architecture. These components will work in tandem with various critical components such as safety PLCs or safety contactors to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, undervoltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.

Benefits of Using Connection Boxes in Light Curtain Installations

Using a connection box with safety light curtains offers a range of performance and safety advantages:

- Simplified Wiring Architecture: Connection boxes eliminate complex wiring runs by centralizing connections for emitters, receivers, muting sensors, and override switches.

- Enhanced System Reliability: Built-in diagnostics, secure connection points, and fault detection improve uptime and reduce maintenance overhead.

- Rapid Deployment and Maintenance: Modular cable systems and quick-release connectors streamline setup, testing, and troubleshooting.

- Scalable Integration: Suitable for multiple safety light curtain models and control systems, enabling future scalability.

- Compliance with Machine Safety Standards: Facilitates compliance with international safety categories such as PLe/SIL3.

Connection boxes from leading suppliers such as ReeR are widely adopted across logistics, packaging, and manufacturing sectors for their flexibility, robust construction, and integration with advanced control panels.

Selecting the Right Connection Box for Your Application

Choosing the appropriate connection box involves evaluating the following factors:

- Application Requirements: Consider the number of devices to be connected, input/output logic, and whether muting, override, or safety relay support is needed.

- Cable Type and Length: Select between single-ended and double-ended cables to match installation distances. Use dedicated cables like F39-JD3B-L for specific models.

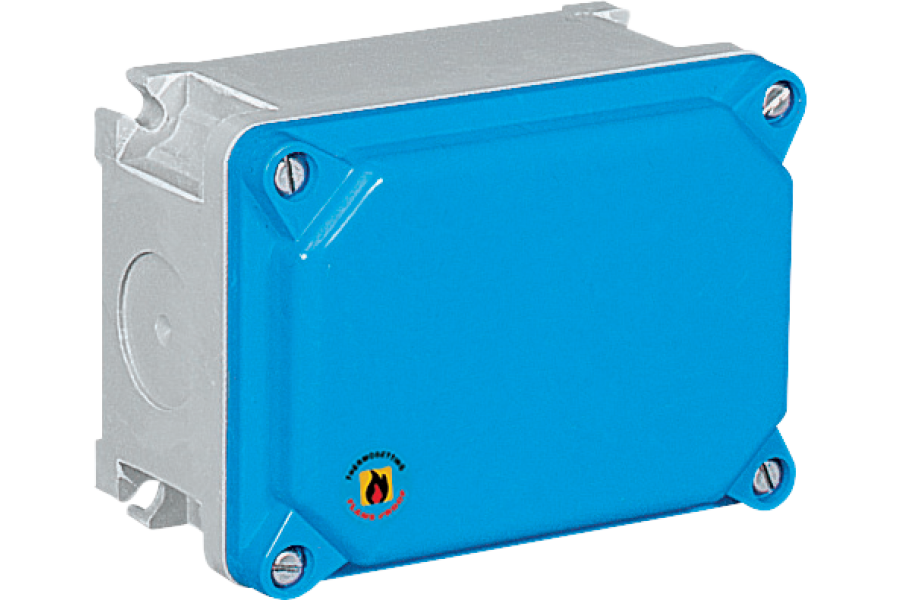

- Environmental Considerations: For applications in dusty or wash-down environments, opt for IP-rated enclosures with protective covers.

- Mounting Style and Bracket Options: Evaluate fixed vs. adjustable bracket kits (e.g., F39-LJB3-M6K) based on equipment layout.

- Support for Accessories: Ensure compatibility with muting arms, protective spatter shields, and sensor alignment tools.

Venus Automation offers a wide range of connection boxes and accessories tailored for advanced industrial safety. Whether integrating into new machinery or retrofitting an existing setup, the right connection box plays a crucial role in achieving functional safety, efficiency, and compliance.