Dold Relays Company Overview Dold is a global leader in industrial automation and safety technology, renowned for its high-quality relay solutions. Founded in Germany, Dold…

Dold Relays

Company Overview

Dold is a global leader in industrial automation and safety technology, renowned for its high-quality relay solutions. Founded in Germany, Dold has maintained a steadfast commitment to innovation, engineering excellence, and compliance with the strictest international safety standards. Their product portfolio includes safety relays, monitoring devices, and control solutions designed for a wide range of industrial applications.

Products and Solutions

Dold offers a diverse array of products tailored to meet the specific safety and control needs of modern industrial systems. From precision monitoring to fail-safe switching, Dold relays are trusted worldwide for reliability and performance.

SAFEMASTER Product Range

Dold safety relay modules are the cornerstone of the SAFEMASTER series, enabling critical safety functions such as emergency stop, guard door monitoring, and two-hand control. These modules are engineered with forcibly guided contacts and cross-circuit detection to prevent unintended operations and provide reliable feedback to safety controllers.

Beyond relays, the SAFEMASTER family includes a comprehensive range of safety devices such as safety mats, enabling switches, light curtains, and emergency stop buttons. These components work in tandem with Dold relays to form complete safety circuits that respond quickly and reliably to hazardous conditions. Integrated systems help simplify certification with standards like EN ISO 13849 and IEC 62061. The SAFEMASTER series represents Dold’s flagship range of safety technology, including emergency stop relays, safety gate monitors, two-hand control relays, and light curtain interfaces. Designed to comply with EN ISO 13849 and IEC 62061, these relays provide Category 4 protection and SIL-rated reliability. Dold safety relays like the OA 5603 are equipped with forcibly guided contacts to ensure fail-safe operation in critical environments.

These relays are commonly used in safety circuits that monitor emergency stop buttons, safety mats, and guard locking systems. Typical output contacts include 2 N/O (normally open) + 1 N/C (normally closed), with contact material options such as AgSnO2 for high durability and low contact resistance. Many SAFEMASTER relays also feature LED indicators to visually confirm operating states, power availability, and fault conditions.

Dold electromechanical relays are an essential part of the SAFEMASTER system. Within this line-up, safety relay modules provide an interface between operator safety devices and machine actuation, offering clear diagnostics and configurable outputs. These modules simplify compliance with safety standards and reduce the design complexity of safety control systems. , delivering the mechanical reliability and switching strength needed in high-risk applications. These relays enable redundant circuit paths, critical shutdown operations, and mechanical state monitoring with forcibly guided contact architecture. Dold safety relay modules are frequently installed in series with safety light curtains, E-stop buttons, and safety switches to form complete safety circuits.

VARIMETER Series for Electrical Safety

VARIMETER devices also play an essential role in speed monitoring and power supply stability. Dold offers specialized speed monitoring relays that detect under speed, overspeed, and standstill conditions in rotating equipment, helping prevent mechanical damage and ensuring operator safety. These are frequently used in conveyor systems, centrifuges, and mixers where speed control is critical.

Additionally, Dold provides power supply monitoring relays that supervise voltage fluctuations, phase loss, and phase sequence in three-phase systems. This guarantees a reliable power environment for sensitive automation and safety devices, protecting them from failure or downtime. VARIMETER relays provide precision monitoring of electrical parameters including voltage, current, frequency, and phase. Popular models like the IP 9077 and AI 940 are widely used for detecting under voltage, phase failure, and frequency anomalies in power distribution systems, contributing to improved uptime and system integrity. LED indicators on VARIMETER units offer real-time status feedback, streamlining diagnostics and maintenance.

Dold electromechanical relays are often used in combination with VARIMETER devices to physically interrupt circuits when monitored conditions fall outside specified ranges. This pairing ensures automated fault handling and layered protection in high-availability environments.

Innovative Drive Technologies: MINISTART/POWERSWITCH

The MINISTART and POWERSWITCH product families offer innovative motor control solutions including soft starters and switching relays. These devices support energy-efficient drive applications, protect against inrush currents, and offer smooth ramp-up functionality for motors. Dold’s relay modules play a crucial role in motor protection and process optimization.

Automation Solutions

Dold relays are central to automation systems, serving as critical components in the control architecture of modern machinery and process environments. Whether used in discrete manufacturing, batch processing, or building management, these relays facilitate seamless integration of sensor inputs, actuator outputs, and safety logic into a unified automation platform.

In industrial automation systems, Dold relays are applied for:

- Controlling conveyor systems, robotic arms, and motors

- Interfacing between low-voltage control signals and high-power switching operations

- Coordinating safety functions with standard PLC logic using relay-based isolation

- Providing redundancy and fail-safe shutdown in emergency conditions

Their compatibility with automation standards and modular design allows engineers to tailor systems for specific applications while ensuring compliance with international safety regulations. Combined with advanced diagnostics, LED indicators, and compatibility with fieldbus systems, Dold relays enhance the reliability and visibility of complex automation systems.

Dold relays are central to automation processes, offering precise timing, signal conditioning, and control switching. In particular, Dold safety relay modules play a key role in bridging automation and safety, ensuring controlled intervention when unsafe conditions arise. Timer relays with adjustable delay, multifunctional timers, and compact interface relays allow engineers to implement sophisticated logic without the complexity of PLCs. These include:

- On-delay relays: Activate output after a pre-set time following the input signal.

- Off-delay relays: Maintain output for a set time after input signal removal.

- Flasher relays: Alternate output between on and off states at set intervals.

- Multifunction timer relays: Support multiple timing functions in one device.

These time delay relays are ideal for sequencing operations, soft starts, or managing dwell times in automated processes. Their front-accessible dials and digital displays simplify setup and allow precise time configuration ranging from milliseconds to several minutes.

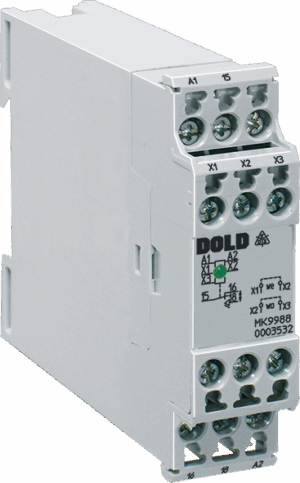

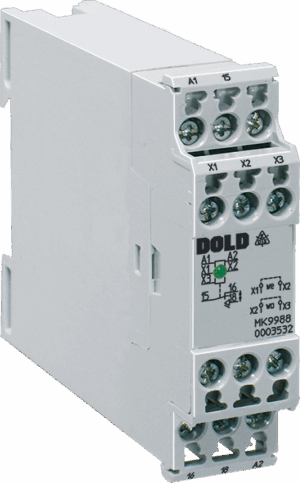

Dold Time Delay Relays

Dold offers a comprehensive range of time delay relays designed to meet diverse industrial automation and safety requirements. These relays are engineered for precise timing control, ensuring reliable operation across various applications.

Key Features of Dold Time Delay Relays:

- Versatile Time Functions: Dold’s relays support multiple timing functions, including on-delay, off-delay, cyclic timing, flasher operations, and more. This versatility allows for tailored solutions in complex control systems.

- Adjustable Time Ranges: With time settings ranging from milliseconds to several hours, users can fine-tune operations to match specific process requirements.

- Robust Design: Built to withstand industrial environments, Dold relays feature durable construction, ensuring longevity and consistent performance.

- Compliance with Standards: Dold’s time delay relays conform to international standards such as IEC/EN 61812-1, ensuring safety and compatibility in global applications.

- User-Friendly Interfaces: Many models come equipped with intuitive controls, such as rotary switches and LED indicators, facilitating easy setup and monitoring.

Notable Models Include:

- MK 7850N: A multifunction relay offering up to 10 time functions, including on-delay, off-delay, and cyclic timing, with adjustable time ranges from 0.02 seconds to 300 hours.

- RK 7817: Designed for compact installations, this relay provides 8 time functions and is suitable for both AC and DC applications.

- MK 9906N: Features on-delay functionality with selectable time ranges up to 300 hours, ideal for applications requiring extended timing operations.

Dold’s time delay relays are integral components in automation systems, offering precise control and enhancing the safety and efficiency of industrial processes.

Dold relays are designed to accommodate a variety of supply voltages, making them suitable for both international standards and specific application needs. Common coil voltage options include:

- 24V DC: Frequently used in industrial automation and control panels

- 110V AC / 230V AC: Suitable for mains-powered systems, particularly in building automation and machinery

- 12V DC and 48V DC: Applied in compact or battery-powered environments

These options ensure compatibility with a broad range of power systems. Dold relays also offer tolerance to voltage fluctuations and include surge protection features in select models, improving reliability in unstable electrical environments.

Dold offers a wide range of relay types tailored to various industrial and safety applications. Each relay type is designed to meet specific operational needs, from control signal switching to critical safety functions:

- Electromechanical Relays: Traditional relays using physical contacts for switching. Known for reliability and high current capacity, commonly used in general automation and energy systems.

- Solid-State Relays (SSR): Use semiconductor components to switch loads silently and with extremely fast response times. Ideal for high-speed applications, they offer long operational life due to the absence of moving parts.

- Safety Relays: Engineered to comply with rigorous safety standards (e.g., EN ISO 13849, SIL 3), these include forcibly guided contacts to prevent contact welding and ensure safe operation.

- Monitoring Relays: Designed to detect faults in voltage, current, phase sequence, or frequency, helping to avoid equipment damage or downtime.

- Timer Relays: Enable precise time-delay functions including on-delay, off-delay, and multifunctional timing for sequence control in automated systems.

- Interface Relays: Serve as signal adapters between control-level and field-level components, often used to protect PLC inputs and outputs.

Dold’s general-purpose relays, including contact protection and switching relays like the BA 7961, deliver dependable performance in control circuits. Meanwhile, Dold safety relay modules provide category-compliant safety switching capabilities for systems that demand rigorous functional safety, such as those conforming to Performance Level e (PL e) and SIL 3 requirements. Their high switching capacity, compact design, and wide coil voltage range make them suitable for a variety of automation and energy management applications. Output contacts are available in multiple configurations including SPDT (single pole double throw), DPDT (double pole double throw), and specialized multi-channel arrangements for safety redundancy. Dold also offers models with 2 to 4 output contacts, which can be configured as normally open (N/O), normally closed (N/C), or a mix of both. Many of these are implemented as changeover contacts—also known as SPDT—where one common terminal alternates connection between two other terminals. These changeover contacts are especially useful for controlling alternate circuits, switching between power sources, or reversing motor direction. A changeover contact provides both a normally closed and a normally open path from a shared terminal, making it highly versatile for dynamic switching operations where logic reversal or backup circuit activation is required. In safety applications, they can be used to monitor both active and inactive states of safety devices, enhancing redundancy and reliability. Their mechanical simplicity and clear ON/OFF feedback make them ideal for automation and safety applications like alarm systems, control switching, and safety interlocks. This versatility enables integration into a wide range of safety circuits and logic designs.

Dold electromechanical relays provide a mechanical switching solution that is easy to test and diagnose. Their tactile response and visible contact operation make them ideal for systems that require periodic inspection or manual override. These relays also serve as robust final elements in emergency stop loops or motor isolator functions.

Relay contacts in Dold devices are precision-engineered using materials such as silver-nickel (AgNi), silver-cadmium oxide (AgCdO), and silver-tin oxide (AgSnO2), depending on the load type and switching frequency. These contact materials are carefully selected for their conductivity, arc resistance, and resistance to contact welding under load. Dold engineers continually refine the surface treatment and shape of relay contacts to minimize contact bounce and optimize signal transfer. In applications involving frequent load switching or harsh conditions, robust contact designs prevent material degradation and ensure safe, stable operation. These contacts are designed to ensure long service life, low arc erosion, and consistent performance in both inductive and resistive circuits. Visual indicators such as LEDs are included on many models to indicate relay coil activation or fault conditions, aiding in fast troubleshooting.

Relay performance is evaluated across several critical factors:

- Switching Capacity: Dold relays offer high current and voltage handling suitable for both low-voltage DC and industrial AC circuits.

- Mechanical and Electrical Lifespan: Optimized contact materials and design deliver hundreds of thousands to millions of switching operations depending on the model.

- Response Time: Electromechanical relays provide typical switching times in the range of 5–20 ms, while solid-state relays operate in microseconds. Dold SSRs, in particular, are valued in applications requiring near-instantaneous switching performance.

- Vibration and Shock Resistance: Dold designs incorporate robust housings and mounting to endure harsh environments.

- Thermal Stability: Heat-resistant components and thermal protection features ensure stable performance even in high-duty-cycle applications.

In addition to electromechanical relays, Dold also offers solid-state relays (SSRs) for applications requiring silent operation, faster switching, and extended electrical life. SSRs are ideal for high-speed control of resistive loads and are commonly used in temperature control systems and automated test equipment.

Dold electromechanical relays remain a preferred choice for integrators looking for reliable, serviceable, and widely compatible switching devices that perform consistently even in demanding industrial conditions.

Electronic Enclosures

To support their electrical components, Dold offers rugged, modular electronic enclosures that ensure environmental protection and ease of installation. These enclosures are engineered to accommodate Dold’s relays and monitoring devices, simplifying integration into control cabinets.

Dold’s Product Finder Tool

Dold provides an intuitive Product Finder Tool on their website, enabling engineers and purchasers to quickly identify the right safety relay, timer relay, or monitoring module. The tool filters by application, function, and electrical specification, reducing time-to-selection and improving procurement efficiency.

Recent Technological Advancements

Dold is also advancing its integration of security software to protect programmable relays and network-connected modules from cyber threats. As industrial automation becomes increasingly interconnected, the risk of unauthorized access and tampering rises. Dold addresses this by incorporating authentication protocols, secure boot mechanisms, and encrypted communications into select relay systems. These security software layers ensure safe relay programming, parameter configuration, and real-time monitoring across industrial networks. Especially in safety-critical applications, where relay behavior must remain predictable and tamper-proof, Dold’s embedded security solutions help manufacturers meet both operational safety and cybersecurity compliance standards. Dold continues to push the envelope in functional safety and monitoring by integrating digital diagnostics, modular design, and plug-and-play capabilities into their latest relay models. Recent developments include smart relays with communication interfaces for Industry 4.0 environments.

Customer-Oriented Approaches

Dold’s engineering support team collaborates closely with OEMs, system integrators, and distributors to offer tailored solutions. Their commitment to flexible configuration and rapid delivery ensures that customers receive the best-fit product for every safety and automation challenge.

Functional Safety Focus

Dold’s safety relays meet the highest industry certifications, including Category 4, SIL 3, and Performance Level e (PLe). Each device undergoes rigorous testing and quality control to deliver unparalleled functional safety in applications like emergency stop circuits, guard locking, and two-hand control.

Certified Safety Technologies

Dold relays incorporate certified technologies such as forcibly guided contacts, cross-circuit detection, and redundancy architectures. These features make them indispensable in applications requiring maximum operational safety and regulatory compliance.

Trade Fairs and Events

Dold regularly participates in leading automation and safety technology expos including SPS – Smart Production Solutions and Hannover Messe. These events allow professionals to interact with Dold’s latest innovations and consult with technical experts in person.

Global Reach and Industry Applications

With distributors and partners across Europe, Asia, and Australia, Dold relays are used in a wide variety of sectors—from automotive manufacturing and food processing to renewable energy and mining. Their global reach is supported by a robust logistics network and multilingual support resources.

Key Industry Sectors and Applications

Dold relays are trusted in:

- Machine guarding and robotics

- Power distribution and load monitoring

- Conveying systems and packaging machinery

- Renewable energy control panels

- HVAC and building automation

- Complex safety applications requiring dual-channel architecture and diagnostic feedback

Dold’s Commitment to Safety and Innovation

Safety is not just a feature—it’s the foundation of Dold’s engineering philosophy. Through constant innovation, investment in R&D, and feedback from field applications, Dold delivers relays that evolve with industrial needs.

Vision for the Future

Dold envisions a future where safety and automation co-exist seamlessly through intelligent relays, digital interfaces, and globally harmonized compliance standards. Sustainability and customer-centric development will remain key pillars of growth.

How to Learn More About Dold Relays

Contact Venus Automation to discuss bulk procurement, technical requirements, or system design consultations.