Dold Monitor Relays: Reliable Monitoring for Industrial Safety Introduction In industrial environments, electrical safety and machine reliability are paramount. Unplanned downtime, undetected faults, and inadequate…

Dold Monitor Relays: Reliable Monitoring for Industrial Safety

Introduction

In industrial environments, electrical safety and machine reliability are paramount. Unplanned downtime, undetected faults, and inadequate monitoring systems can lead to catastrophic failures. Dold monitor relays address these challenges through advanced relay technology designed to provide reliable, continuous supervision of electrical and mechanical parameters. This article explores how Dold’s monitoring solutions enhance plant safety, prevent damage, and ensure compliance with safety standards.

What is a Dold Monitor Relay?

Dold monitor relays are safety components designed to track specific parameters such as voltage, current, insulation resistance, phase sequence, and standstill status of rotating machinery. They serve as integral parts of safety control systems, triggering alarms or shutdown procedures when thresholds are crossed.

Originating from Dold & Söhne KG, a German leader in electrical safety and automation, these relays are a part of the VARIMETER and SAFEMASTER product lines. They are widely used across industries for applications where uninterrupted performance and worker safety are critical.

Benefits of Dold Monitor Relays

Improved Industrial Safety

By continuously monitoring essential parameters, Dold relays help prevent accidents caused by electrical faults, motor stalls, and insulation breakdowns. They are especially effective in Category 4 / SIL 3 safety applications.

Equipment Protection and Longevity

Dold monitoring relays detect abnormal conditions early, allowing operators to take corrective action before equipment suffers irreversible damage. This leads to extended asset life and reduced maintenance costs.

Reduced Downtime

With real-time supervision and configurable alarms, these relays help avoid unexpected shutdowns, keeping production lines and automated systems running smoothly.

Compliance with Safety Standards

Dold relays are compliant with EN ISO 13849, IEC 60204-1, and IEC 62061, enabling companies to meet legal and insurance requirements for machine safety.

How Dold Monitor Relays Work

Dold relays use electromechanical or solid-state circuits to measure electrical or mechanical values. When a deviation from normal conditions is detected (e.g., under voltage, overcurrent, standstill), the relay actuates its relay contacts to disconnect power, signal a fault, or trigger a safety routine.

The relays often include changeover contacts, LED indicators, and adjustable time delays to fine-tune behaviour and ensure precise performance.

They are engineered to detect direct contact hazards—such as loss of insulation or exposed live wires—and activate emergency response measures. In many cases, the relay is designed with a limited extent of permissible deviation, meaning it will only tolerate predefined parameter drift before initiating a shutdown.

Additionally, some models use auxiliary voltage supplies to power monitoring logic independently of the load voltage, ensuring the relay remains operational even during line faults.

Fault indicators provide a clear visual or digital alert when abnormalities are detected, aiding in fast diagnosis and recovery. Indicators for operating status show live feedback on system health, allowing operators to monitor ongoing performance without needing additional instrumentation.

These features together support preventive maintenance by allowing early detection of wear, electrical instability, or system imbalance, significantly reducing the risk of downtime and extending component life.

Dold monitor relays are compatible with both single-phase and three-phase AC systems. In single-phase systems, they monitor voltage presence, current draw, and insulation resistance to protect standalone machines and control panels. In three-phase systems, relays ensure proper phase sequence, detect phase loss or asymmetry, and provide comprehensive protection for motors and rotating equipment often used in heavy industry.

Types of Dold Monitoring Relays

VARIMETER Insulation Monitors

These detect insulation faults in IT systems, even during live operation. They prevent fires and electric shocks, ideal for medical and industrial equipment.

Voltage and Phase Monitoring Relays

These monitor phase sequence, phase failure, and voltage asymmetry to protect motors and sensitive electronics.

Current Monitoring Relays

Useful for detecting overload, underload, and motor jam conditions, improving the reliability of conveyor systems and pumps.

Standstill and Speed Monitoring Relays

From the SAFEMASTER SBR series, these ensure that rotating parts have fully stopped before allowing access to hazardous areas.

Single-Phase and 3-Phase AC-Systems

Dold monitor relays are built to operate seamlessly across both single-phase and 3-phase AC-systems, ensuring flexibility for a wide range of industrial applications.

In single-phase AC systems, Dold relays monitor basic parameters such as voltage levels, insulation resistance, and load current. These are commonly used in smaller machines, building automation, and control panels where protection against under voltage or insulation faults is critical.

In 3-phase AC systems, which are standard in heavy industry and high-powered motors, Dold relays add value by monitoring:

- Phase sequence to prevent motor reversal

- Phase loss for immediate disconnection during faults

- Phase asymmetry to catch imbalance conditions that damage equipment

These capabilities are particularly useful for conveyor systems, pumps, fans, and motor-driven production lines.

Their integration helps maintain operational reliability and safety across diverse electrical setups.

Technical Specifications

Nominal Voltage Ranges

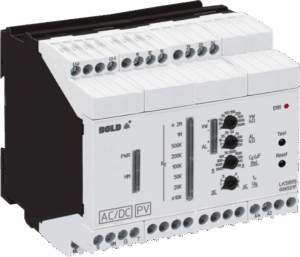

Dold monitor relays support a wide range of nominal voltages, typically from AC/DC 24 V to 240 V depending on the model. This makes them versatile across different electrical systems and applications.

Enclosure Design

Most models feature a compact DIN-rail mountable enclosure made from high-durability, flame-retardant plastic. Enclosures are designed to meet IP20/IP40 protection classes, with select models offering higher ingress protection for industrial environments.

General Electrical Characteristics

- Response Time: Adjustable (typically 100 ms – 10 s)

- Supply Voltage Tolerance: ±15%

- Output Contacts: 1 or 2 changeover relays (NO/NC)

- Contact Material: Silver alloy with gold flash for high reliability

- Indication: LED status indicators for power, error, and threshold

- Auxiliary Voltage: Independent input to power internal logic during faults

- Direct Contact Detection: Triggers immediate disconnection on live contact faults

- Limited Extent Tolerance: Activates response once deviation crosses pre-set limits

- Fault Indicator: LED or digital output to indicate fault type and location

- Operating Status: Real-time signal of normal or abnormal operation

- Preventive Maintenance: Supports scheduled service through early anomaly detection

- System Compatibility: Suitable for single-phase and three-phase AC networks

Implementation Guidelines

Installation and Setup

- Mount on DIN rails

- Connect according to circuit diagrams (normally open / closed contacts)

- Adjust setpoints via onboard dials or digital settings

Required Equipment

- Appropriate relay type (voltage, current, standstill, etc.)

- Multimeter or oscilloscope for verification

- PLC or safety controller integration (optional)

Best Practices

- Calibrate during commissioning

- Test under fault conditions to verify performance

- Use LED indicators for diagnostics

Use Examples

- Packaging Plants: Speed monitoring relays used to ensure safe access to motor-driven cutter heads

- Power Stations: Insulation monitors detect early faults, avoiding system-wide failures

- Elevator Systems: Phase monitoring relays prevent motor damage due to phase loss or reversal

Misconceptions and Clarifications

“Monitoring relays are optional”

False — in safety-critical systems, monitoring relays are mandatory for compliance with machine safety standards.

“They slow down production”

On the contrary, they help avoid unplanned stoppages, improving overall efficiency.

Challenges in Deployment

Complex Selection Process

Choosing the right relay for the right application can be difficult. Dold provides product finders and datasheets to simplify this.

Integration with Legacy Equipment

Older systems may require retrofitting or custom wiring, but Dold supports integration through universal contact types and wide voltage ranges.

Future Outlook

As Industry 4.0 evolves, Dold is integrating smart features such as IO-Link, remote diagnostics, and predictive monitoring into its relays. This will enhance real-time visibility and facilitate smarter maintenance practices.

Conclusion

Dold monitor relays are an essential part of modern industrial safety infrastructure. Whether you are protecting motors, ensuring safe access to machinery, or meeting compliance requirements, Dold offers robust, reliable monitoring solutions for every need.

Contact Us

Have any Technical questions about Dold Monitor Relays or need help selecting the right product for your application? Our technical team is here to assist you.

Contact us if you need help with:

- Choosing a relay for specific nominal voltage requirements (24 V, 110 V, 230 V, etc.)

- Understanding enclosure design (IP ratings, DIN-rail compatibility)

- Clarifying response time, contact material, and changeover contact specs

- Integrating monitor relays with PLCs or legacy control systems

- Downloading datasheets, wiring diagrams, or compliance documents

- Interpreting specifications for auxiliary voltage, direct contact faults, and limited extent triggers

- Understanding fault indicators, operating signals, and maintenance alerts

📧 Email: [email protected]

📞 Phone: +61 3 9553 5688

🌐 Website: venusautomation.com.au/contact

Let us help you protect your machines and improve operational safety.