What Are Power Relays? Definition and Basic Functionality Power relays are electrically actuated switching devices that allow low-power control signals to operate high-power circuits. Acting…

What Are Power Relays?

Definition and Basic Functionality

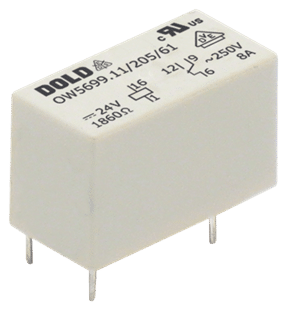

Power relays are electrically actuated switching devices that allow low-power control signals to operate high-power circuits. Acting as an interface between control electronics and power equipment, these devices ensure safe and efficient switching in a wide range of applications, from lighting systems to industrial machinery. Power relays are critical in enabling automation, energy efficiency, and system protection, especially where manual switching would be impractical or unsafe. They offer electrical isolation between the control circuit and the power load, minimizing risks associated with surges, faults, or overloads.

Distinction Between Power Relays and Signal Relays

Signal relays are engineered for low-voltage, low-current switching—ideal for transmitting signals or performing logic-level control in electronics and communication systems. In contrast, power relays are designed to switch high currents (often exceeding 10A) and high voltages (up to several hundred volts), making them suitable for motor loads, heating elements, or large lighting systems. Power relays feature more robust contact materials, larger switching gaps, stronger actuation mechanisms, and additional protections like arc suppression and thermal insulation.

Types of Power Relays

Electromechanical Relays

Electromechanical power relays consist of a coil, armature, spring, and one or more sets of electrical contacts. When voltage is applied to the coil, a magnetic field is generated, moving the armature and changing the state of the contacts. These relays are highly versatile and widely used in control panels, process automation, motor starters, and HVAC systems. Auxiliary contacts enable integration into feedback loops, safety interlocks, and multi-stage control circuits.

Solid State Relays

SSRs replace mechanical contacts with semiconductor switching elements such as thyristors or triacs. They offer silent operation, faster switching speeds, and longer lifespans due to the absence of moving parts. SSRs are ideal in high-speed automation, temperature control, and noise-sensitive environments, such as medical equipment or instrumentation panels.

Key Features of Power Relays

Contact Arcing Prevention: Integrated arc extinguishing chambers, magnetic blowout coils, and contact separation technologies reduce wear caused by arcing, particularly in inductive load switching.

Dust and Contaminant Resistance: IP-rated or hermetically sealed relays prevent ingress of dust, oil, humidity, and corrosive vapors, maintaining performance in harsh industrial conditions.

High Current and Voltage Handling: Power relays are rated to control loads well above 10A and up to several hundred volts. Some models, especially heavy-duty contactors, support over 100A continuous current and are built to withstand high inrush currents from motors and transformers.

Applications of Power Relays

Lighting Systems: Employed in smart building systems, street lighting, and stadium illumination, power relays facilitate group switching, scheduled operation, and load shedding.

High Voltage Applications: In substations, energy storage arrays, and electric vehicle chargers, power relays help isolate DC and AC circuits for safety, maintenance, and fault management.

Industrial Automation: Power relays enable programmable logic controllers (PLCs) to control actuators, pumps, solenoids, and fans in real-time. They also act as intermediaries between soft starters and motors, helping reduce mechanical stress and electrical surges.

Innovations in Power Relay Technology

Crystalline Dust Growth Prevention: Special coatings and encapsulation techniques minimize the risk of internal crystal formation, which can lead to unintended conduction paths and premature failure.

Advanced Material Use: Contacts are increasingly made from silver-tin oxide, copper-tungsten, or gold-flashed alloys, offering higher resistance to welding and pitting from repetitive arcing.

Smart Relay Technologies: These relays provide self-diagnostics, cycle counters, load monitoring, and temperature sensing. Smart models may feature LED indicators, communication ports, or support for Modbus/CAN protocols for seamless integration with smart grid or Industry 4.0 platforms.

Selecting the Right Power Relay

Operational Requirements: Determine the relay’s coil voltage, switching capacity, contact configuration (SPDT, DPDT, etc.), and maximum surge current tolerance. Matching the relay to the application avoids overloads and mechanical wear.

Environmental Considerations: Harsh settings require sealed or ruggedized enclosures, while temperature extremes demand materials rated for wide operating ranges.

Load Type and Specifications: Capacitive and inductive loads impose different stress profiles on the relay. The wrong match can lead to contact welding, insufficient break performance, or excessive switching noise.

Market Trends and Developments

Growing Demand for Renewable Energy Applications: As solar, wind, and battery systems become more common in commercial and industrial use, power relays are evolving to support higher DC voltages, bidirectional current flow, and grid-tied safety protocols.

Miniaturization with Performance Gains: The push for smaller, more powerful devices is driving innovation in PCB relay designs with improved thermal performance, arc management, and surface-mount compatibility.

Integration with IoT and Energy Monitoring Systems: Power relays are increasingly integrated into smart panels, digital energy meters, and predictive maintenance platforms, enabling remote diagnostics and real-time switching data collection.

Broader integration with Safety & Automation Systems

In modern industrial environments, power relays are only one part of an integrated safety architecture. These systems will work in tandem with various critical components such as safety PLCs, safety contactors or safety light curtains (including muting light curtains) to ensure real-time hazard detection and safe machine shutdown. Common peripheral safety devices like the emergency stop button, two hand station, and emergency stop rope pull are all effectively managed by the safety PLC’s logic structure.

Advanced installations frequently incorporate safety relays, safety non-contact switches, RFID switches, mechanical interlock switches, and solenoid locking switches—each adding specific protective functions to the machinery. To maintain continuous system health, engineers also deploy standstill monitors, speed monitors, soft starters, and reversing contactors within their automation frameworks. For measuring the product itself, solutions such as measurement light curtains can be integrated.

Beyond motion and logic safety, electrical condition monitoring is equally essential. Devices like insulation monitors, battery monitors, current monitors, voltage monitoring relays, phase sequence relays, under voltage relays, and undercurrent monitoring relays are often integrated to detect anomalies in power flow or equipment performance, with this data displayable on HMI Touch Panels or similar systems. To support reliable operation, high-quality power relays and regulated power supplies are essential.