Encoders are feedback devices that convert mechanical motion into electrical signals, allowing precise measurement of position, speed, and direction. Whether tracking the angular position of…

Encoders are feedback devices that convert mechanical motion into electrical signals, allowing precise measurement of position, speed, and direction. Whether tracking the angular position of a motor shaft or the linear position of a moving object, encoders play a vital role in modern automation systems.

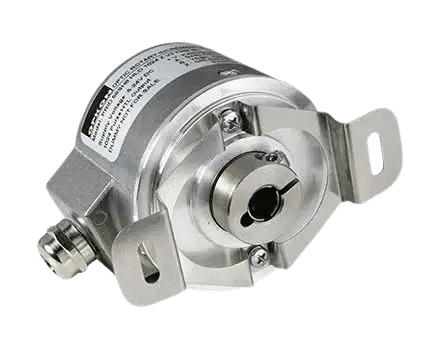

There are different types of encoders including rotary encoders and linear encoders. Rotary encoders, for example, measure shaft position using either incremental or absolute output signals. A quadrature encoder outputs square wave signals to indicate direction of motion, while a multi-turn absolute encoder tracks both position and the number of full shaft revolutions.

Importance in Motor Control and Automation

Encoders are critical to the performance of servo motors and motor control systems in industrial automation. They provide real-time position feedback to ensure motors follow precise motion paths. This is especially important in applications requiring fine control over angular position, such as robotic arms, CNC machinery, and volume control systems.

Whether using a magnetic rotary encoder for heavy-duty applications or an optical encoder for high-resolution positioning, selecting the right feedback device significantly enhances control accuracy and system responsiveness.

Types of Encoders

Absolute Encoders

An absolute encoder provides a unique digital code for each angular position of the encoder shaft. Unlike incremental encoders, absolute encoders maintain position data even after power loss. Options include single-turn encoders and multi-turn encoders, both suited for different levels of precision and shaft rotations.

Absolute position measurements are crucial for applications where re-homing is not practical, such as in multi-axis automation systems. Absolute multi-turn encoders use magnetic sensing or optical sensors to track shaft position across multiple revolutions.

Incremental Encoders

Incremental encoders generate output signals each time the encoder shaft rotates by a fixed angle. These output pulses—often in square wave format—provide information on direction of rotation, shaft revolutions, and position changes. Measurement resolution depends on pulses per revolution (PPR), a key spec when selecting a device for precise measurement tasks.

An incremental encoder interface is commonly used in automation systems for real-time speed monitoring and direction of travel detection.

Magnetic Encoders

Magnetic encoders use a magnetic sensor and rotating magnetic poles to detect shaft position. These encoders are valued for their compact size, resistance to mechanical wear, and suitability in harsh environmental conditions.

Magnetic technologies enable reliable performance in high-vibration or dusty settings, making them ideal for industrial applications where durability is a priority. Magnetic rotary encoders are available in both incremental and absolute versions, often featuring hollow shaft or solid shaft options.

Comparing Absolute and Incremental Encoders

Precision Feedback and Position Accuracy

Absolute encoders excel in applications requiring exact position tracking—even during power cycles—while incremental encoders are typically chosen for their high-speed feedback and simple interface.

For systems needing high-accuracy position feedback, absolute position encoders ensure each point on the encoder shaft correlates to a specific digital signal. Meanwhile, incremental encoders provide phase difference output signals used to calculate direction and speed in servo systems.

Suitability for Different Applications

Absolute encoders are ideal for robotics, elevators, and automation systems requiring continuous positional awareness. Incremental encoders suit high-speed operations such as conveyors, motors with digital output control, and mechanical encoders where cost-efficiency is critical.

The choice depends on whether your system requires absolute position data or relative movement tracking.

Magnetic Encoders in Harsh Environments

Durability and Reliability

Magnetic encoders provide exceptional reliability under challenging environmental conditions. Unlike optical encoders, they do not rely on fragile components, making them more resilient to dust, oil, vibration, and temperature fluctuations.

Heavy-duty applications benefit from hollow shaft magnetic encoders that can withstand shaft misalignment and mechanical stress. Their magnetic sensing ensures consistent signal generation, even in less-than-ideal operating environments.

Factors for Selection in Tough Conditions

When selecting encoders for tough environments, consider:

- Shaft type (e.g. hollow shaft encoder)

- Sealing against contaminants

- Resistance to mechanical wear

- Mounting configuration (Encoder Mounting)

- Magnetic vs optical technology

Magnetic encoders with compact housings and rugged materials are often preferred in extreme conditions where traditional optical encoders may fail.

Choosing the Right Encoder

Consideration of Motor Types

The type of motor being used significantly influences encoder selection. Servo motors, for example, benefit from encoders with high pulses per revolution and accurate angular position tracking. For linear motors, linear encoders offer direct feedback on travel distance.

Systems requiring direction of motion tracking or precise rotational position monitoring may opt for rotary encoders with integrated magnetic technologies.

Encoder Mounting Options

Encoder mounting plays a crucial role in ensuring accurate feedback and long-term reliability. Options include shaft-mounted, hollow shaft, and flange-mounted encoders.

Proper encoder mounting helps minimize mechanical wear, ensures proper alignment with the motor shaft, and reduces vibration. When selecting an encoder, consider space constraints, environmental conditions, and cable orientation.

Integration with Mitsubishi Industrial Motor Control

Comprehensive Solutions

Mitsubishi’s industrial automation ecosystem integrates seamlessly with a wide range of encoders for motor control, ensuring optimal feedback and communication with PLCs and drives. From digital signal processing to precise measurement of shaft revolutions, Mitsubishi systems support both absolute and incremental encoder interfaces.

These solutions are tailored for complex industrial applications requiring absolute position, speed control, and robust feedback loops.

Enhancing Automation and Efficiency

By combining encoders with Mitsubishi’s motion control products, manufacturers benefit from enhanced system efficacy and streamlined feedback integration. Applications include robotic arms, conveyor systems, and multi-axis machines, where encoder position data is critical for synchronization and accuracy.

Using Mitsubishi-compatible feedback devices ensures long-term stability in demanding automation tasks.

Optimizing Motor Performance with Encoders

Ensuring Reliable Feedback

Reliable feedback is the cornerstone of precise motor control. Encoders enable real-time monitoring of motor shaft position, direction of rotation, and counts per revolution—data that drives responsive, adaptive control loops in automation systems.

Choosing a feedback device with suitable measurement resolution and robust output signals prevents drift and ensures consistent performance.

Improving System Efficacy

With the right encoder, systems operate with enhanced precision and lower error margins. Quadrature encoders improve directional accuracy, while absolute encoders reduce initialization delays. Digital code signals from optical or magnetic sensors streamline motion control, leading to faster cycle times and reduced downtime.

For high-performance applications, the integration of encoder technologies ensures efficient energy use, smoother motion, and long-term reliability.