Risk Assessment

ak_dev2025-03-12T05:58:07+10:00

RISK ASSESSMENT PLANT AND EQUIPMENT

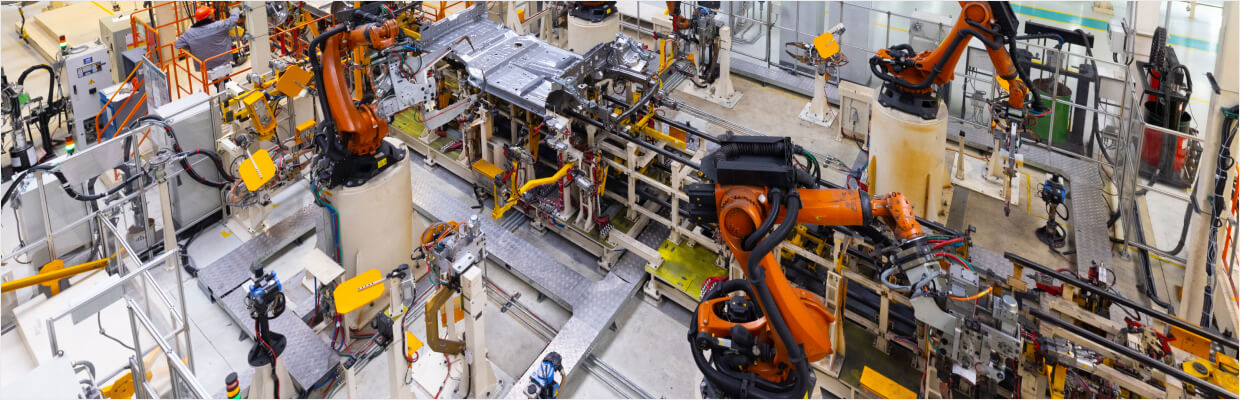

Analyse, understand and beat your Plant and Equipment Safety Risk

PLANT ASSESSMENT

- An on-site examination of plant and equipment

- Analysis of primary hazards

- Evaluating existing risk reduction principles

- Comparison of machine compliance with existing regulations

- Priority list (hierarchy of risk)

- Plant assessment report

RISK ASSESSMENT

- On-site inspection

- Consultation with all relevant personnel

- Provide a detailed report documenting risk control recommendations

SAFETY DESIGN

- Safety requirement specification

- Detailed electrical, mechanical, software and control system design

- Component selection

- Engineering drawings for easier upgrading and installation of safety devices

VALIDATION ANALYSIS

- Assessment of existing design against safety requirements

- Evaluate selected components

- Test of safety related hardware and software equipment

Our Blogs

Variable Speed Drives Explained: Types, Functions, and the Difference Between VSDs and VFDs

VSDs and VFDs

Definition and Overview.

Variable Speed Drives (VSDs) and Variable Frequency Drives...Servo Motor Overheating: Causes, Prevention, and Solutions

Understanding Servo Motor Overheating

Servo motor overheating is one of the most common and...How to Choose the Right Servo Motor

Definition and Functionality

Servo motors are high-performance actuators used to precisely control the angular...Subscribe Our Newsletters

Get all the latest information on Events, Sales and Offers.